Pulverized coal suspension combustion characteristic trial furnace for cement kiln

A characteristic test, suspension combustion technology, applied in the field of thermal analysis instruments, can solve the problems of different burnout time, very different working conditions, low heating speed, etc., to achieve the effect of rapid analysis ability, time saving and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

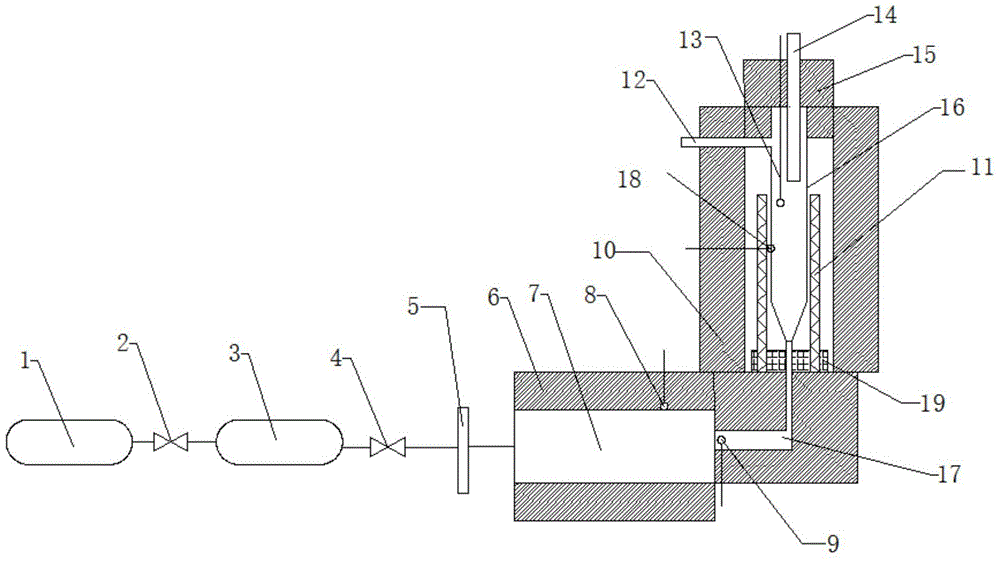

[0024] Pulverized coal suspension combustion characteristics test furnace for cement kiln, including air source system, heat gun 7, "L" shaped quartz tube 17, furnace heating system, and suspension furnace temperature monitoring and acquisition system;

[0025] The air source system includes an air compressor 1, a first pressure reducing valve 2, a gas pressure regulator tank 3, a second pressure reducing valve 4 and a gas flow meter 5; the gas outlet of the air compressor 1 passes through the first pressure reducing The valve 2 is connected to the inlet of the gas surge tank 3, and the outlet of the gas surge tank 3 is connected to the inlet of the gas flow meter 5 through the second pressure reducing valve 4;

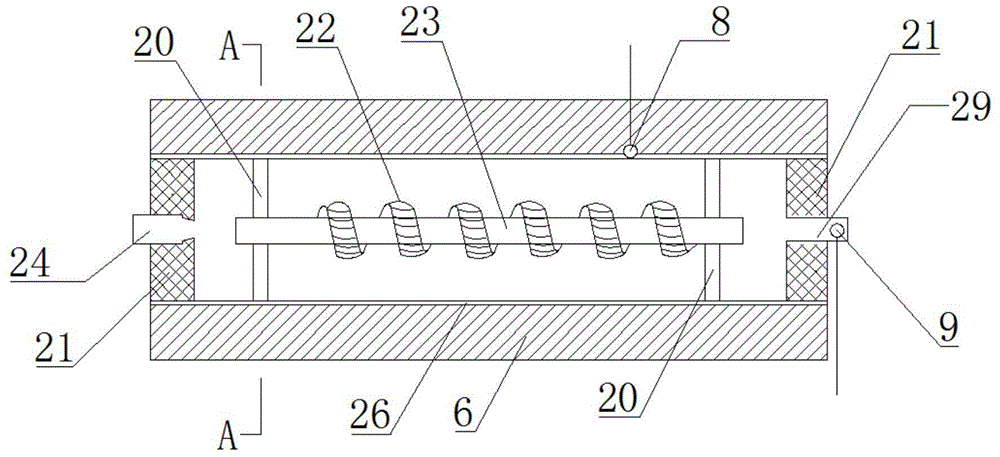

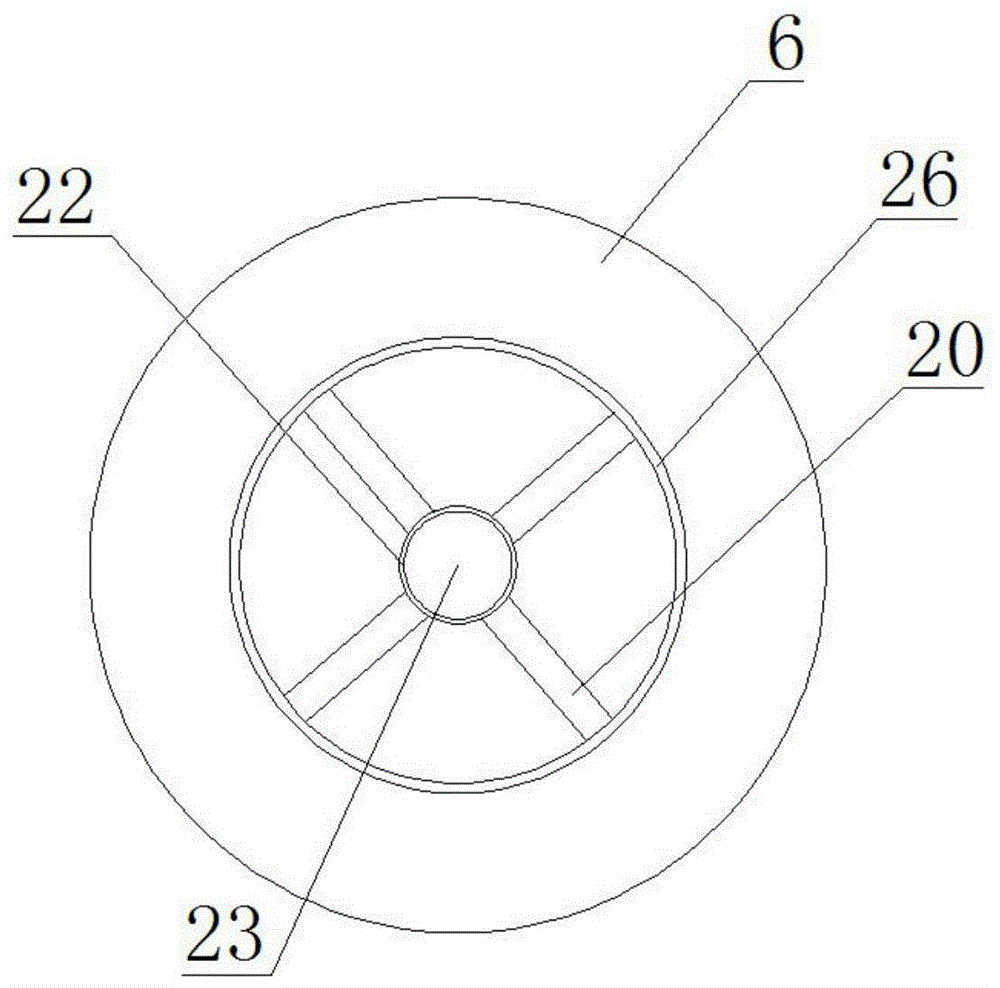

[0026] Described heat gun 7 comprises ceramic tube 26, high temperature resistant gelling material 21, gas inlet 24, gas outlet 29, ceramic column 23, support frame 20, heat gun high temperature resistance wire 22, heat gun overtemperature protection thermocouple 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com