Laser self-mixing interference system with feedback light intensity self-adaptive adjustment function

A self-mixing interference, self-adaptive adjustment technology, applied in control/adjustment systems, general control systems, instruments, etc., can solve complex problems such as the inability to fix reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

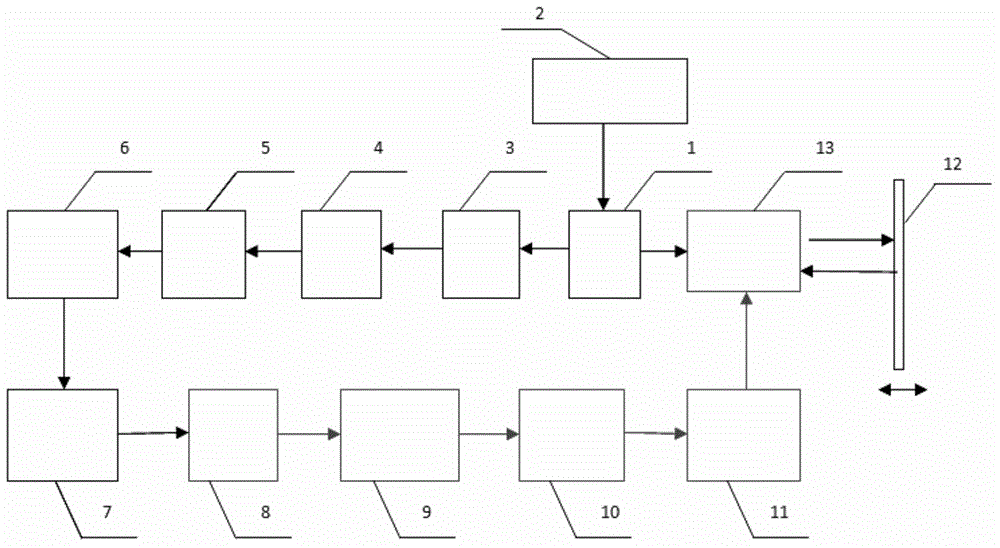

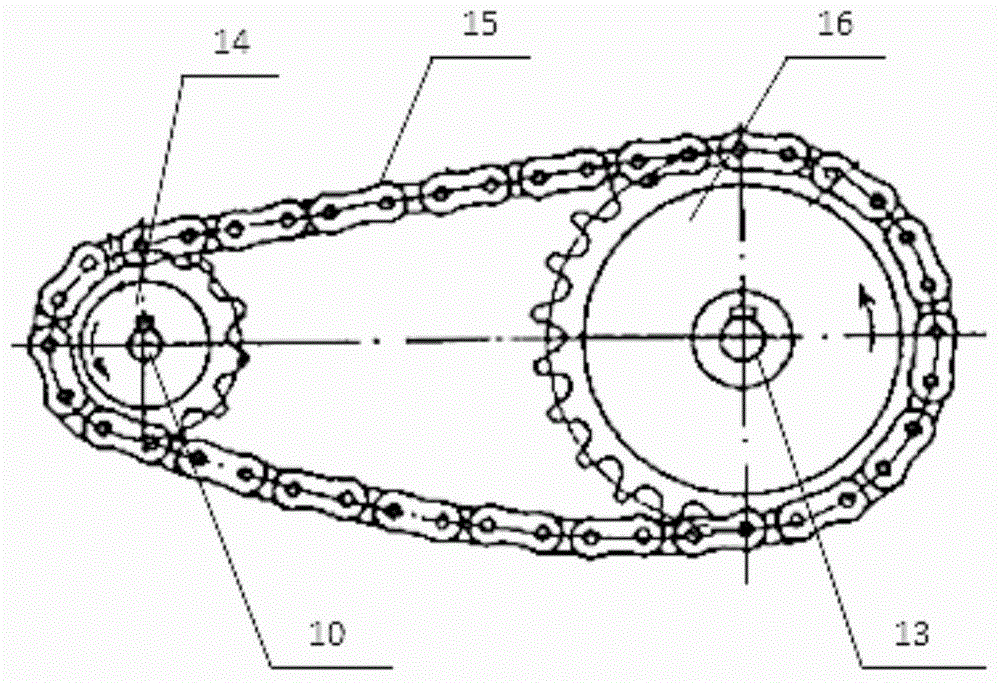

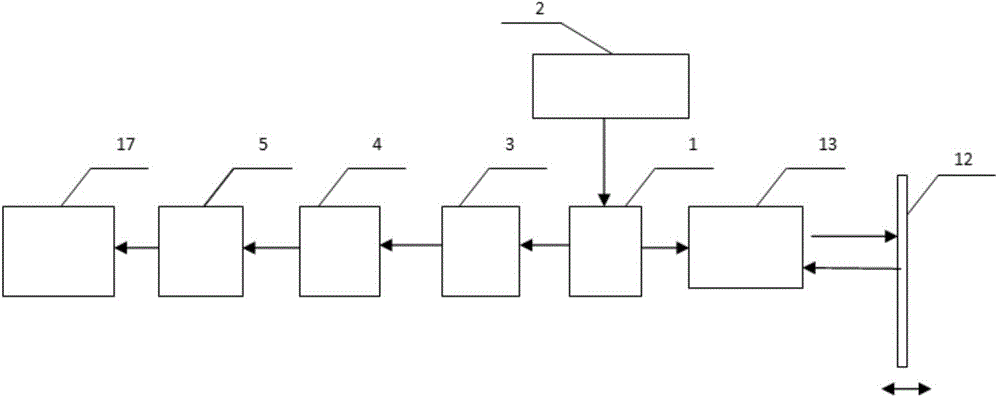

[0021] See attached figure 1 , The laser self-mixing interference system with adaptive adjustment of feedback light intensity includes: laser (1), which emits laser outward; driving power (2), which drives the laser; photodetector (3), which receives the laser from the laser and outputs the same An electric signal proportional to the laser intensity; a transimpedance amplifier (4) for amplifying the output signal of the photodetector; a filter (5) for filtering the signal amplified by the transimpedance amplifier (4); data acquisition card (6) Collect the signal filtered by the filter (5) and output it to the upper computer (7); the upper computer (7) receives the data collected by the data acquisition card (6) for processing, and outputs the processing result To the microcontroller (8); the microcontroller (8) receives the output result from the upper computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com