Novel insulated cable

A new type of cable technology, applied in the direction of insulated cables, power cables, insulated conductors, etc., can solve the problems of unable to meet the requirements of high current of the system, unable to restore electrical performance, increased production costs, etc., to achieve good rodent resistance, light weight, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings.

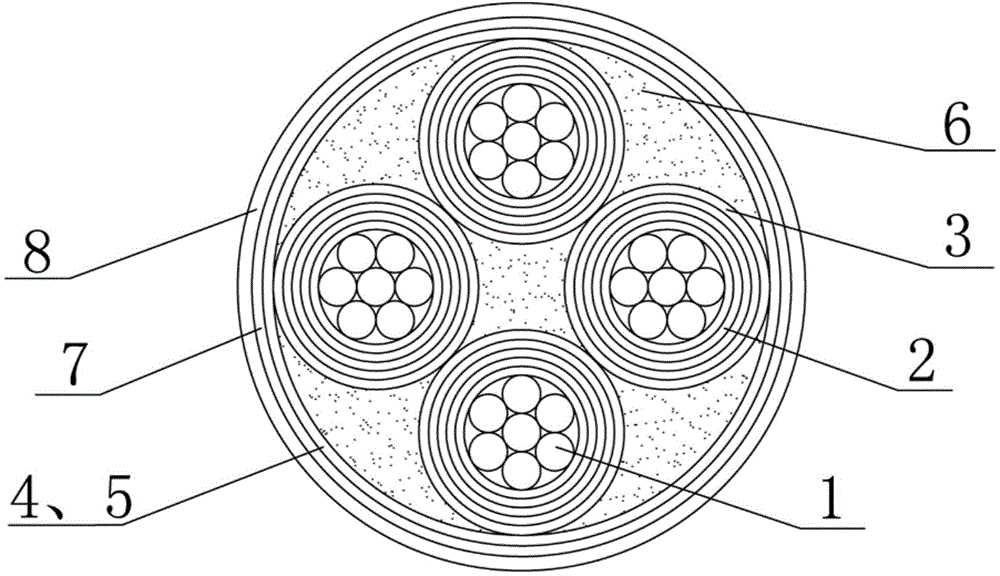

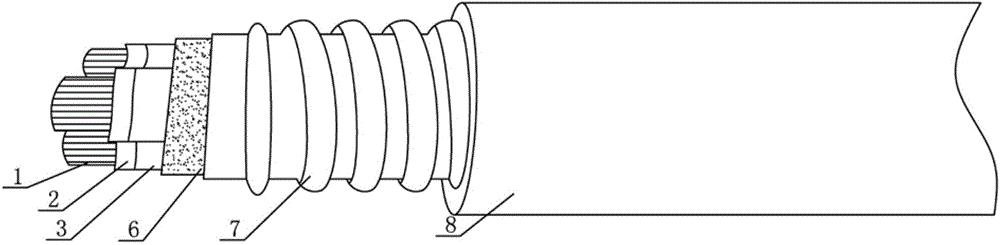

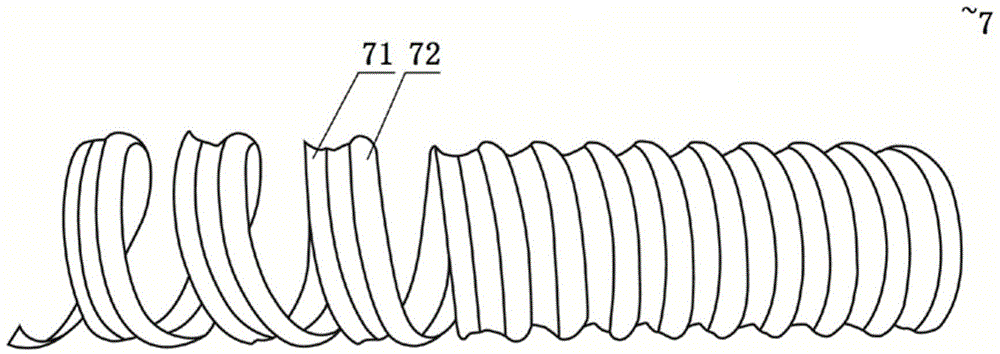

[0029] combine figure 1 and figure 2 , the novel fire-resistant insulated cable of the present invention, the cable comprises: at least one core conductor 1, each core conductor is covered or wound with a fire-resistant layer 2 and an insulating layer 3, and the entire cable core is covered or wound with a The oxygen barrier layer 4 and the cladding layer 5 are provided with a filling layer 6 between the core conductors 1 and between the entire cable core and the oxygen barrier layer 4 . Each core conductor 1 is formed by winding at least two aluminum alloy cores, and the preferred model of the aluminum alloy cores is: A8030.

[0030] Comparing AA-8030 aluminum alloy conductor and copper conductor, it is found that due to the difference in resistivity, their IACS is different. AA-8030 aluminum alloy is 61.8% of copper. When we increase the cross-sectional area of al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com