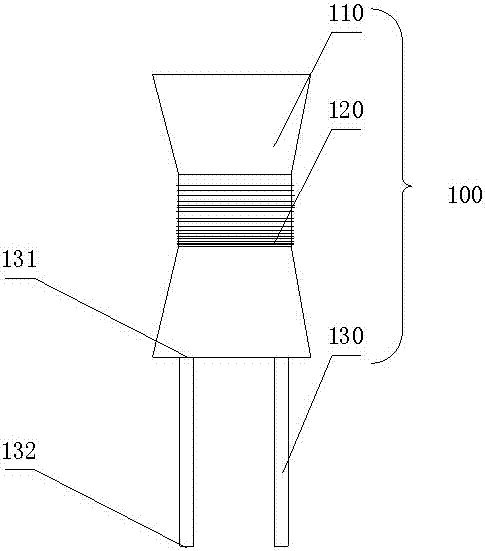

Inductance element and its preparation process

A technology for inductive components and outer layers, which is applied in the field of inductive components and its preparation process, can solve the problems of high requirements for magnetic core and coil materials, unsafe use of magnetic cores, and high requirements for compressive resistance of magnetic cores, achieving high pressure resistance, Low pressure resistance, solve the effect of inductance disconnection and no inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

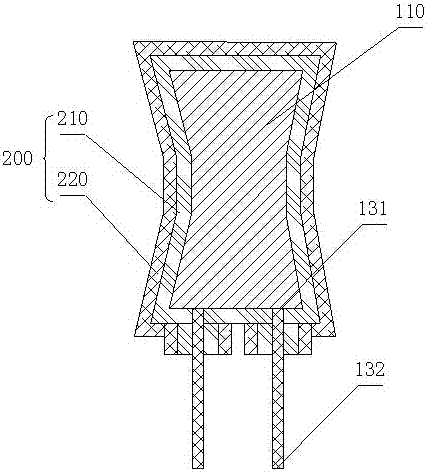

[0043] see figure 2 , the outer protective layer 200 in this embodiment is a wax layer 210 and an epoxy layer 220 arranged sequentially from the inside to the outside, and the wax layer 210 is coated on the magnetic core 110 and / or the coil 120 and part of the leads. On the outer side of the foot 130 , the epoxy layer 220 is coated on the outer side of the wax layer 210 .

[0044] The pin 130 in this embodiment is partially covered in the outer protective layer.

[0045] The preparation process of the inductance element of the present embodiment comprises the following steps:

[0046] S100: Manufacture the magnetic core to obtain the magnetic core; the manufacturing process of the magnetic core is an existing technology, and this embodiment will not repeat it. It should be noted that the preparation process of this embodiment is applicable to inductance elements of magnetic cores of various shapes;

[0047] S200: Winding, winding a metal wire around the magnetic core; the m...

Embodiment 2

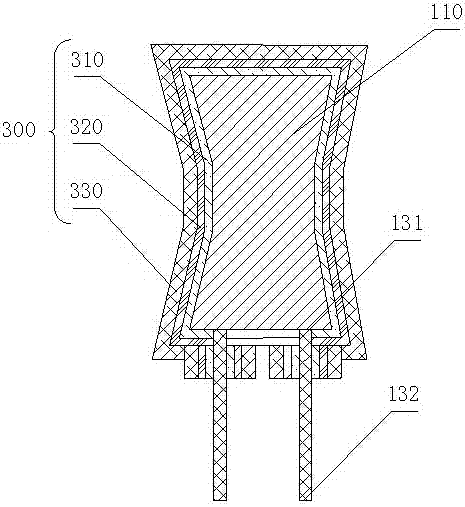

[0065] see image 3 , the outer protective layer 300 in this embodiment is a silicone oil layer 310 , a wax layer 320 and an epoxy layer 330 arranged sequentially from the inside to the outside, and the silicone oil layer 310 is tightly coated on the magnetic core 110 of the inner body 100 And on the coil 120 and part of the pin 130.

[0066] The innermost silicone oil layer of the outer protective layer in this embodiment is tightly coated on the outside of the magnetic core, coil and some pins, then the wax layer is coated on the outside of the silicone oil layer, and then the epoxy layer is coated on the wax layer outside. Setting the silicone oil layer can prevent the epoxy powder from adhering to the pins during the subsequent formation of the epoxy layer, thereby affecting the conductivity of the inductance element; setting the wax layer can ensure that the epoxy powder in the subsequent preparation of the epoxy layer can be well Adsorption, on the other hand, the wax ...

Embodiment 3

[0083] see Figure 4 , the outer protective layer 400 in this embodiment includes a first protective layer 410 wrapped on the outside of the coil 110 and / or the magnetic core 120 and a first protective layer 410 wrapped on the pin 130 and the magnetic core 110 The second protective layer 420 outside the connection end 131 and the pin 130;

[0084] Wherein the first protective layer 410 includes a wax layer 411 and an epoxy layer 412 arranged in sequence from the inside to the outside, the wax layer 411 is coated on the outside of the magnetic core 110 and / or the coil 120, the ring The oxygen layer 412 is coated on the outside of the wax layer 144;

[0085] The second protective layer 420 includes a silicone oil layer 421, a wax layer 422 and an epoxy layer 423 arranged sequentially from the inside to the outside, and the silicone oil layer 421 tightly covers the connection end of the pin and the magnetic core and / or or part on the pins.

[0086] The difference between the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com