Automatic drawing frame for diode

A sliver and diode technology, applied in the field of machinery, can solve the problems of increased manufacturing cost of diodes, difficulty in manual handling of diodes, low work efficiency, etc., and achieve the effects of convenient production and processing, improved production and processing efficiency, and structural energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

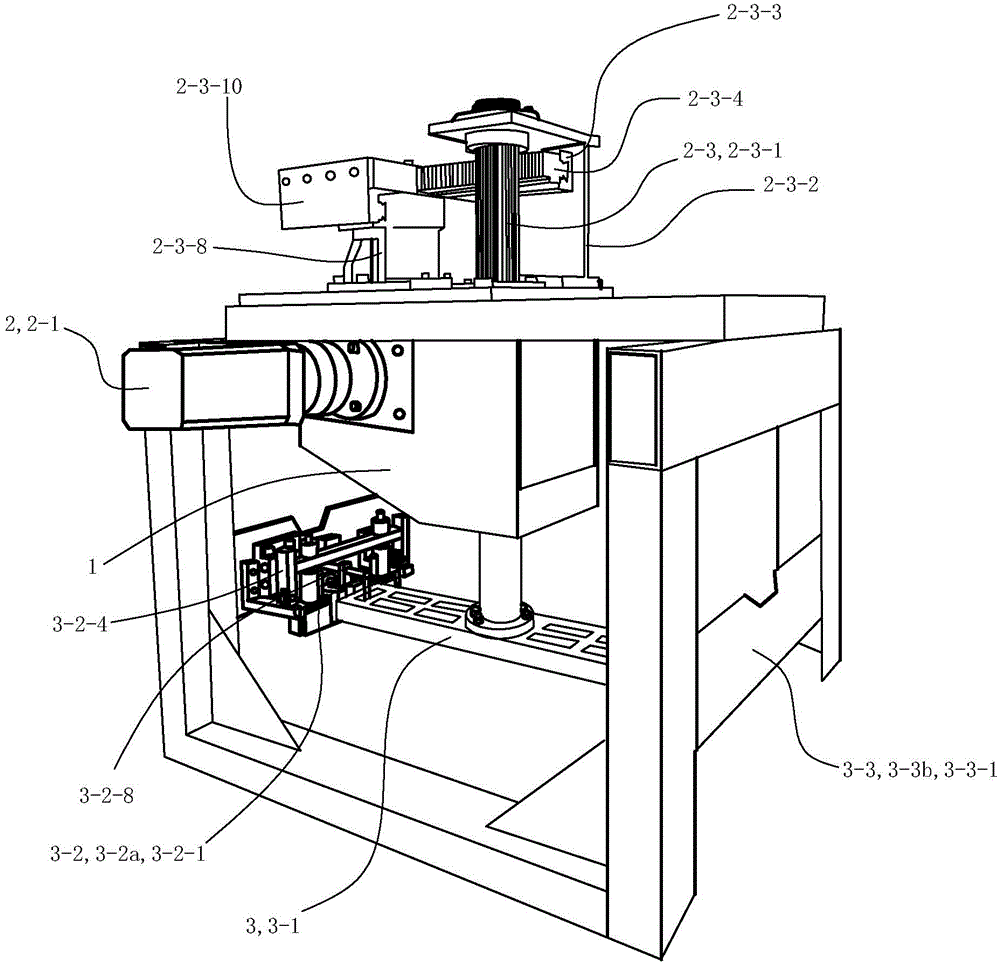

[0072] See figure 1 , The diode automatic sliver machine of the present invention includes a frame 1, a transfer device 2 and a clamping device 3. The transfer device 2 is arranged on the frame 1 .

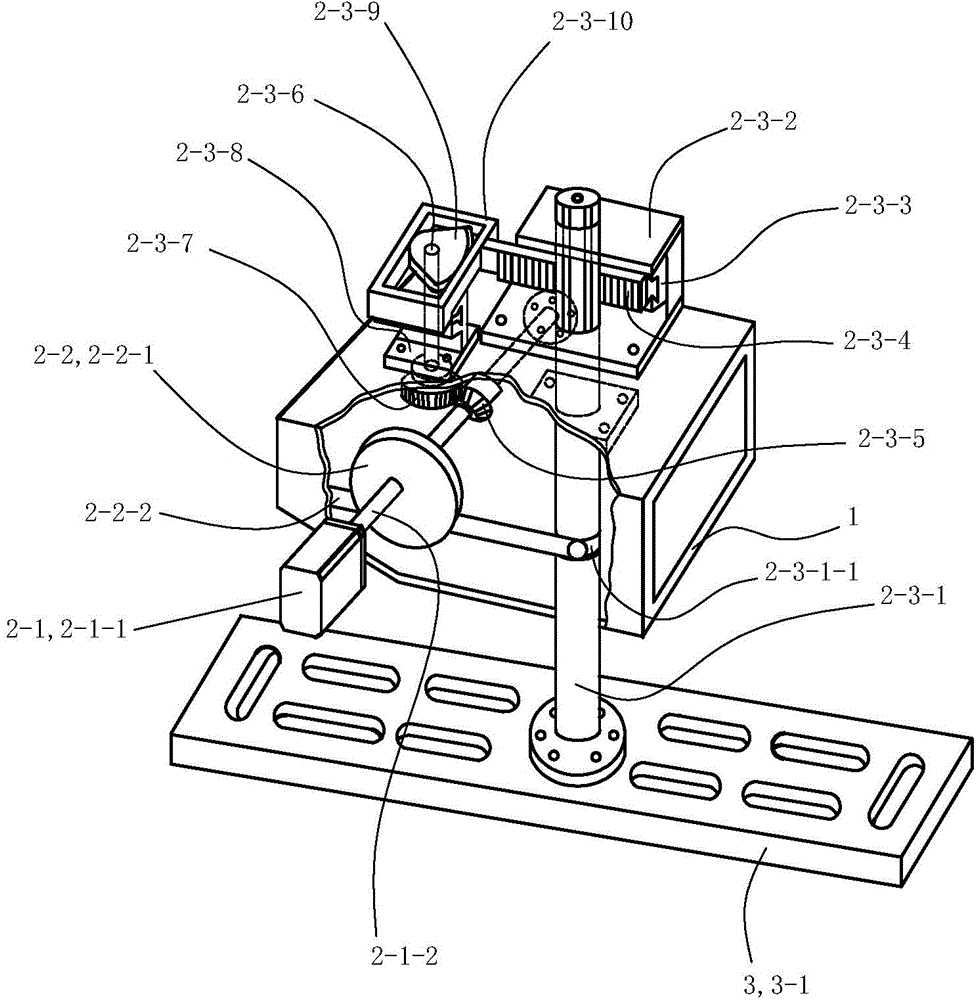

[0073] See figure 2 , The transfer device 2 includes a driving mechanism 2-1, a lifting mechanism 2-2 and a turning mechanism 2-3.

[0074] See figure 1 with figure 2 , the drive mechanism 2-1 includes a motor 2-1-1 and a drive shaft 2-1-2. The motor 2-1-1 is fixedly arranged on the frame 1, and the motor 2-1-1 is arranged horizontally backward by its motor shaft. The drive shaft 2-1-2 is rotatably arranged on the frame, and is connected with the motor shaft transmission of the motor 2-1-1, and the drive shaft 2-1-2 is driven by the motor 2-1-1 to rotate.

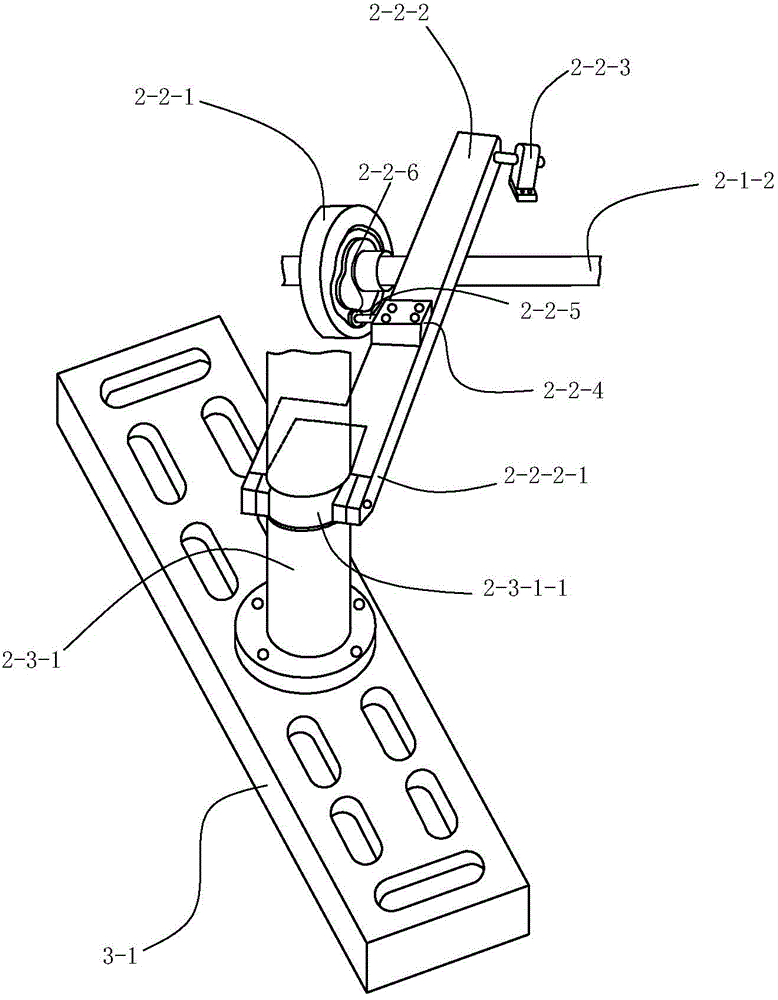

[0075] See figure 2 , image 3 with Figure 7, the lifting mechanism 2-2 includes a lifting cam 2-2-1, an adjusting arm 2-2-2, an adjusting arm mounting seat 2-2-3, an adjusting arm guide seat 2-2-4, and an adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com