Coiling needle of square lithium battery

A lithium battery, square technology, used in secondary batteries, circuits, electrical components, etc., can solve the problems of difficulty in pulling out the winding needle, destroying the alignment of the winding core, and bringing out the inner membrane of the winding core, so as to reduce the winding core. Risk of short circuit, reduction of sliding friction, effect of improved winding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

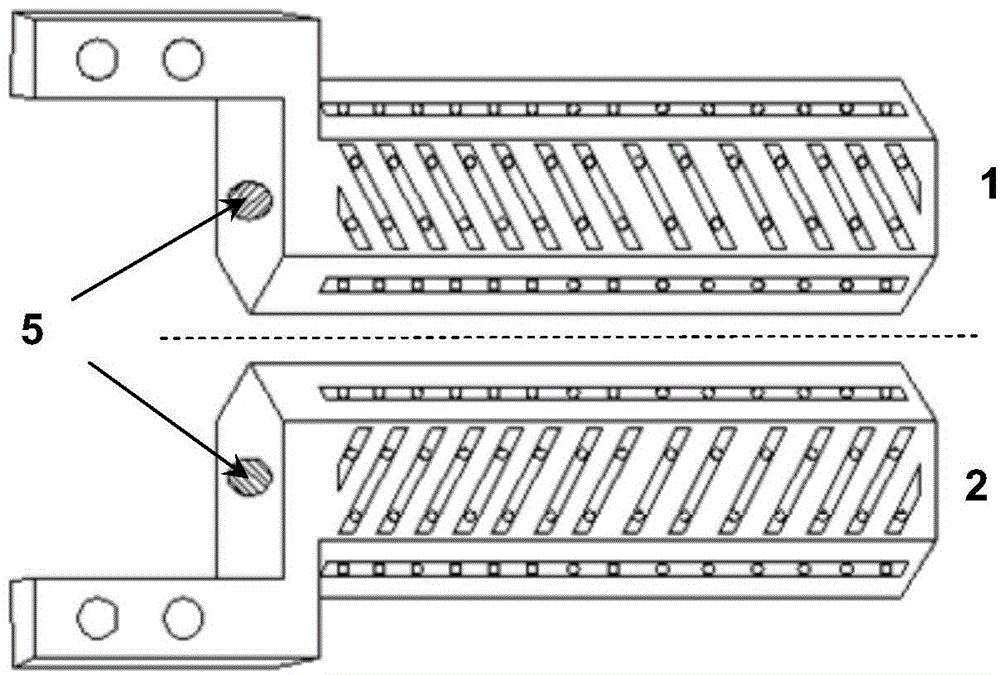

[0018] A square lithium battery winding needle suitable for winding ceramic diaphragms is composed of an upper winding needle 1 and a lower winding needle 2 used in pairs.

[0019] like figure 1 As shown, the winding needle 1 and the winding needle 2 have the same structure and shape. Both the winding needle 1 and the winding needle 2 are composed of a needle core 3 and a shell 4.

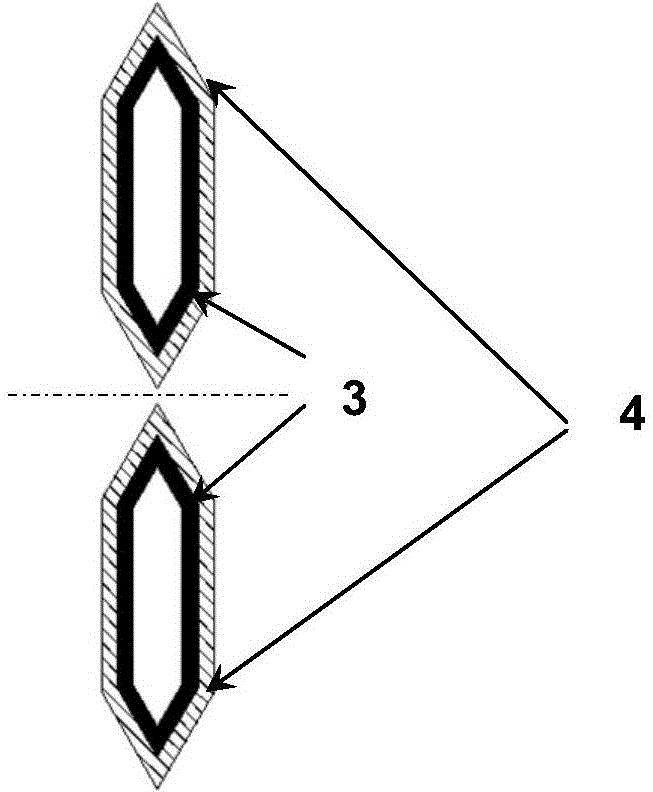

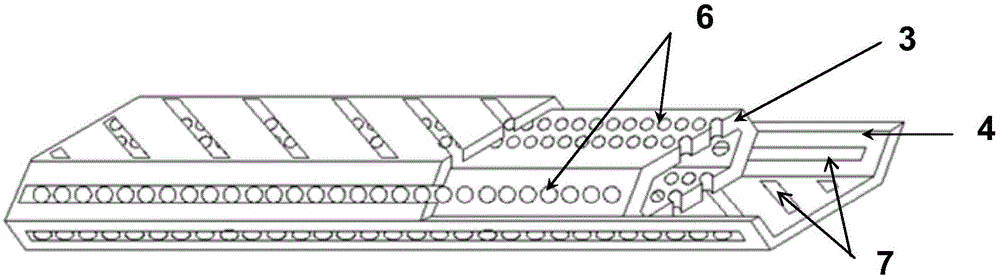

[0020] The needle core 3 is made of stainless steel, and the shape of the needle core is designed as a scabbard with protruding acute angles on both sides ( figure 2 ), the inside of the needle core is hollow, and the side wall of the needle core has evenly distributed air outlet holes 6 . The base of the needle core is designed with an air inlet 5 and a mounting handle communicating with the hollow interior of the needle core, and the mounting handle is provided with a screw hole for installation.

[0021] like image 3 As shown, the shell 4 is a protective layer wrapped on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com