Tank for filtering water of pickling sludge

A technology of pickling sludge and filter tanks, applied in the field of filter tanks, which can solve the problems of inconvenient transportation, industrial production, easy accumulation of products into blocks, and time-consuming, etc., to achieve good practical effect, prevent accumulation into blocks, and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

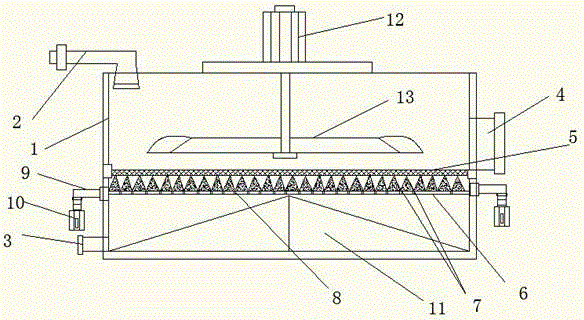

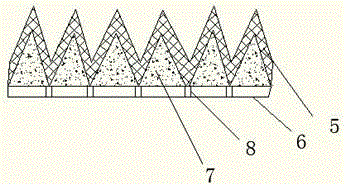

[0016] Example 1: Such as figure 1 A kind of pickling sludge filter water tank shown, the water filter tank is a cylindrical tank body 1, the top of the tank body 1 is provided with a sludge feed port 2, and the bottom of the tank body 1 is provided with There is a drainage port 3, the side of the tank body 1 is provided with a discharge port 4, and the middle part of the tank body 1 is provided with a water filter layer 5, and the water filter layer 5 is an elastic water filter layer. net, the bottom of the water filter layer 5 is provided with a drainage plate 6 that moves up and down in the tank body, and the two ends of the drainage plate 6 are provided with connecting rods 9 that are fixedly connected to the height adjustment motor 10, and the drainage A plurality of triangular drainage blocks 7 are evenly distributed on the plate 6 , and a drainage hole 8 is provided on the drainage plate 6 between two adjacent drainage blocks 7 to communicate with the lower part of th...

Embodiment 2

[0017] Example 2: Such as figure 1 As shown, the top of the tank body 1 is provided with a rotating motor 12, and the rotating motor 12 is connected directly above the water filter layer 5 through the stirring paddle 13; , not only prevent the sludge from clogging the water filter layer 5, but also prevent the pickling sludge from accumulating into blocks under the drive of the stirring paddle 13, and facilitate the collection of small-volume products.

Embodiment 3

[0018] Example 3: Such as figure 1 As shown, the bottom of the tank body 1 is provided with a conical water-guiding outlet plate 11, and the drain outlet 3 is arranged at the bottom of the water-guiding outlet plate 11; The excess pickling waste water in the mud is exported to the filter tank tank body 1 to avoid more waste liquid in the filter tank, and the pickling waste water is transferred to the equipment of the waste water recovery process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com