Preparation method of nanoscale hard alloy

A cemented carbide and nano-scale technology, applied in the field of cemented carbide, can solve the problems of dependence on imports, low tool life, poor surface finish, etc., and achieve the effects of complete metallographic structure, increased cutting speed, and poor surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

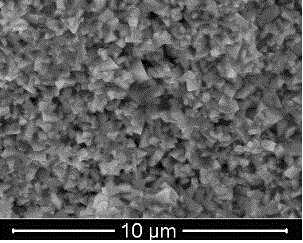

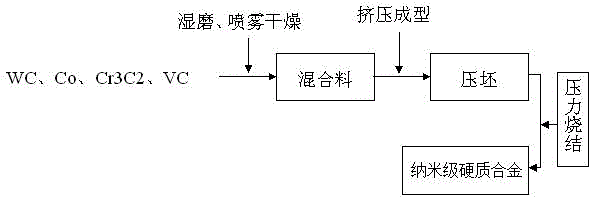

[0013] A preparation method of nanoscale hard alloy. WC powder with nanoscale Fsss particle size of 0.2 μm, Co powder with Fsss particle size of less than 0.8 μm, and a small amount of inhibitor are used as raw materials. The materials are prepared in a mass ratio of 90:9:1, and the mass ratio of vanadium carbide and chromium carbide is 1:2, including WC powder 180KG, Co powder 18KG, vanadium carbide 0.8KG and chromium carbide 1.6KG). Use a 300L wet mill for ball milling, the mass ratio of ultrafine cemented carbide balls to materials is 5.5:1, and the ball milling time is 76 hours. Then the ball milled materials are spray-dried and granulated, and then pressed into standard samples before sintering. The sintering temperature 1390°C, sintering time 1h, sintering pressure 9MPa. Through this embodiment, nanoscale cemented carbide with a grain size of less than 0.4 μm can be prepared.

Embodiment 2

[0015] WC powder with nano-scale Fsss particle size of 0.2 μm, Co powder with Fsss particle size of less than 0.8 μm, and a small amount of inhibitor are used as raw materials, and the materials are prepared according to the mass ratio of 90:9:1. The mass ratio of vanadium carbide and chromium carbide It is 1:2, including WC powder 180KG, Co powder 18KG, vanadium carbide 0.8KG and chromium carbide 1.6KG. Use a 300L wet mill for ball milling, the mass ratio of ultrafine cemented carbide balls to materials is 5.5:1, and the ball milling time is 74 hours. Then the ball milled materials are spray-dried and granulated, and then pressed into standard samples before sintering. The sintering temperature 1385°C, sintering time 70min, sintering pressure 9MPa. Through this embodiment, nanoscale cemented carbide with a grain size of less than 0.4 μm can be prepared.

[0016] The physical properties of nanoscale cemented carbide alloys are shown in the table below.

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com