Modular energy dissipating device and anti-collision pipeline thereof

An energy-dissipating device and a modular technology, applied in water conservancy projects, climate change adaptation, shipping equipment, etc., can solve problems such as poor anti-collision ability, high production cost, unreasonable design, etc., achieve exquisite structural design, reduce production The effect of low cost and strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

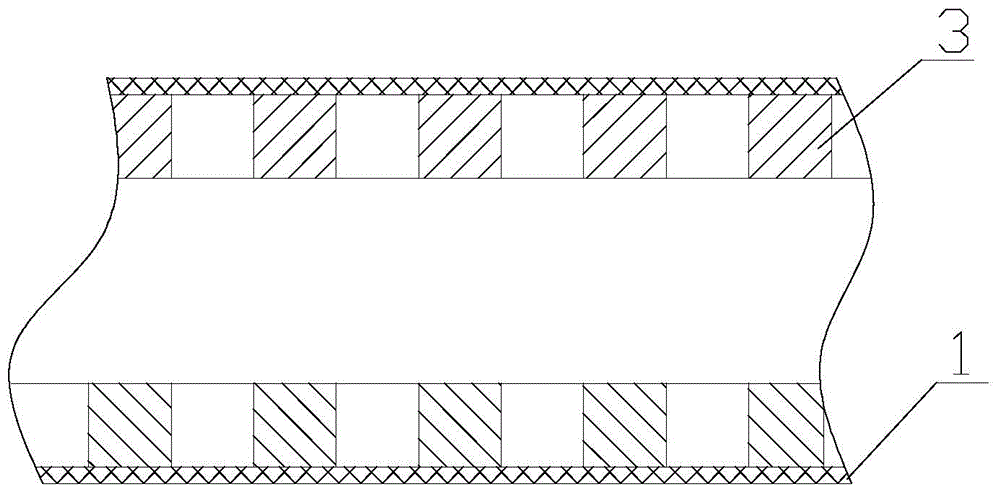

[0029] like figure 1 As shown, a kind of anti-collision pipeline 100 of the present invention comprises an outer tube 1 and several rubber rings 3, each rubber ring 3 is arranged coaxially with the outer tube 1, and the outer surface of each rubber ring 3 is matched with the inner wall of the outer tube 1 . The outer surface of each rubber ring 3 is close to the inner wall of the outer tube 1 , and the outer surface of the rubber ring 3 is closely matched with the inner wall of the outer tube 1 . There is a distance between two adjacent rubber rings 3; on the inner wall of the outer tube 1, a fixing device is provided to prevent each rubber ring 3 from sliding horizontally. The rubber ring 3 is a rubber tire.

[0030] The outer pipe 1 is a composite material pipe. The composite material is made of glass fiber reinforced plastic. The glass fiber reinforced plastic matrix material is one of unsaturated resin, isophthalic resin, ophthalmic resin, vinyl resin, epoxy resin, bis...

Embodiment 2

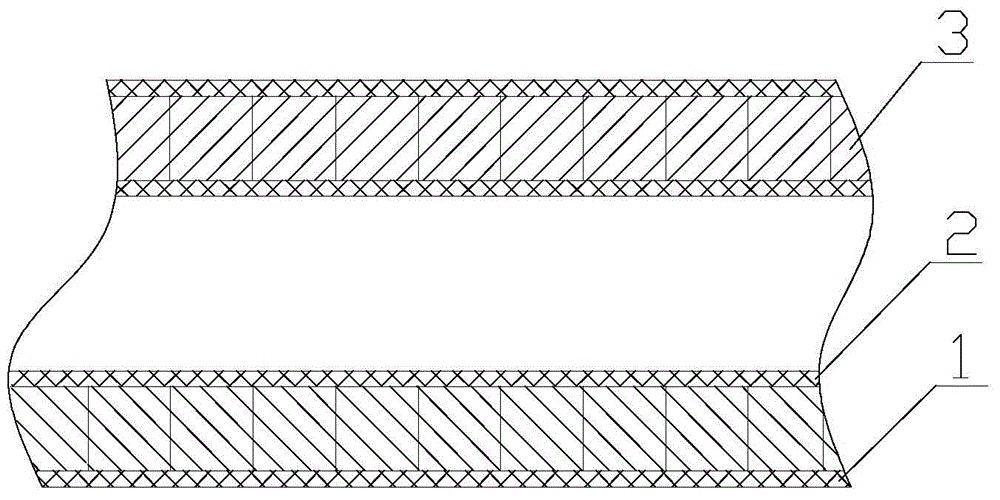

[0032] like figure 2 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that an inner tube 2 is also provided in the rubber ring 3, and each rubber ring 3 is sleeved on the inner tube 2, and the inner tube 2, the rubber ring 3 and The outer tube 1 is arranged coaxially, and the inner tube 2 and the outer tube 1 are composite material tubes; two adjacent rubber rings 3 are tightly connected. After the anti-collision pipeline 100 has a certain length, the two ends of the anti-collision pipeline 100 are provided with sealing covers. The outer pipe 1 can also be a steel pipe. When the outer pipe 1 is a steel pipe, the outer surface and / or inner surface of the outer pipe 1 has an anti-corrosion layer, the anti-corrosion layer is a composite material layer or a paint layer, and generally the inner surface of the outer pipe 1 can be coated with a paint layer, The outer surface of the outer tube 1 is coated with a composite material layer.

Embodiment 3

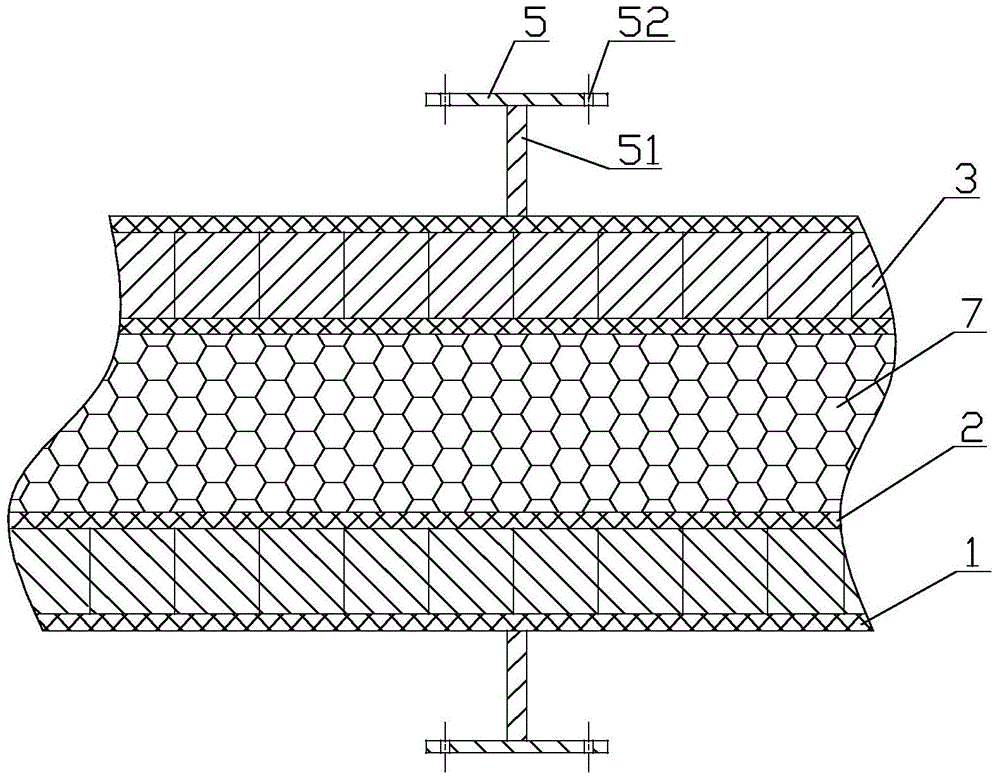

[0034] like image 3 As shown, this embodiment is substantially the same as Embodiment 2, the difference is that there is a filler 7 inside the inner pipe 2, and the filler 7 is polyurethane foam, polyvinyl chloride foam, carbon foam, PEI foam and PMI foam, Balsa wood , paulownia wood, fir or strong core felt. The filler 7 can fill up the lumen of the inner tube 2 .

[0035] like image 3 , Figure 4 As shown, an installation method of the anti-collision pipeline 100 of the present invention, that is, a schematic structural diagram of a modular energy dissipation device, the modular energy dissipation device includes an anti-collision pipeline 100 and a connection fixing seat, and the anti-collision pipeline 100 is fixed On the connection and fixing seat, the anti-collision pipe 100 adopts the anti-collision pipe of the present invention. Wherein, the two anti-collision pipelines 100 can be connected through the connecting loop flange 6 in the length direction, and the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com