Small-size rock core sampling drilling machine based on manned deep submersible vehicle mechanical hand operation

A core sampling and manipulator technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of heavy weight and low operation efficiency, and achieve the effect of cemented carbide structural strength and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

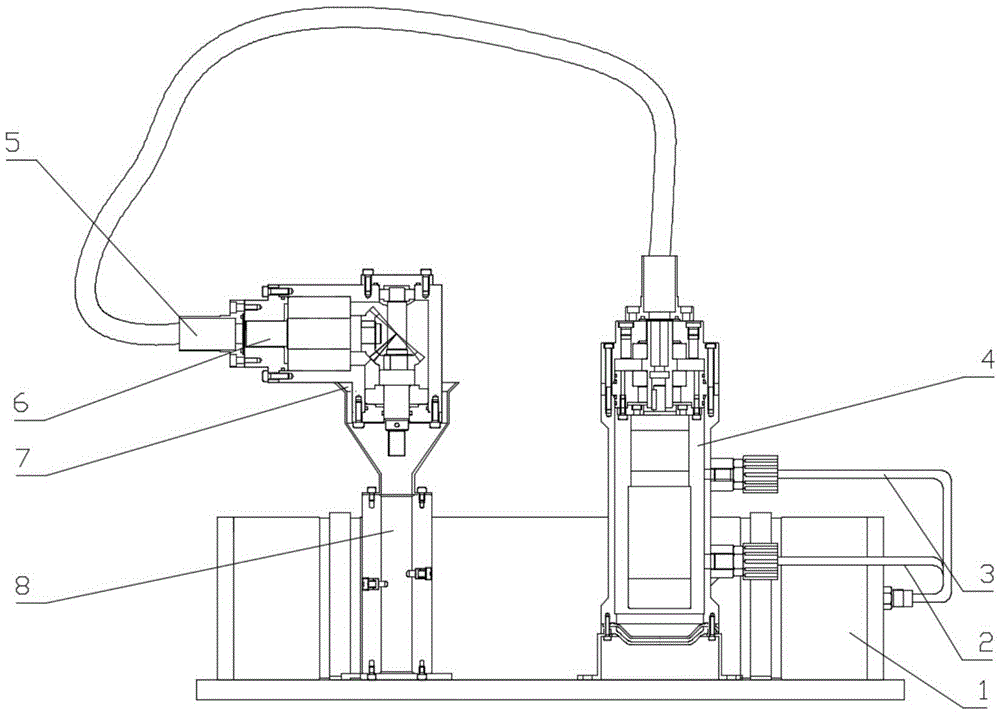

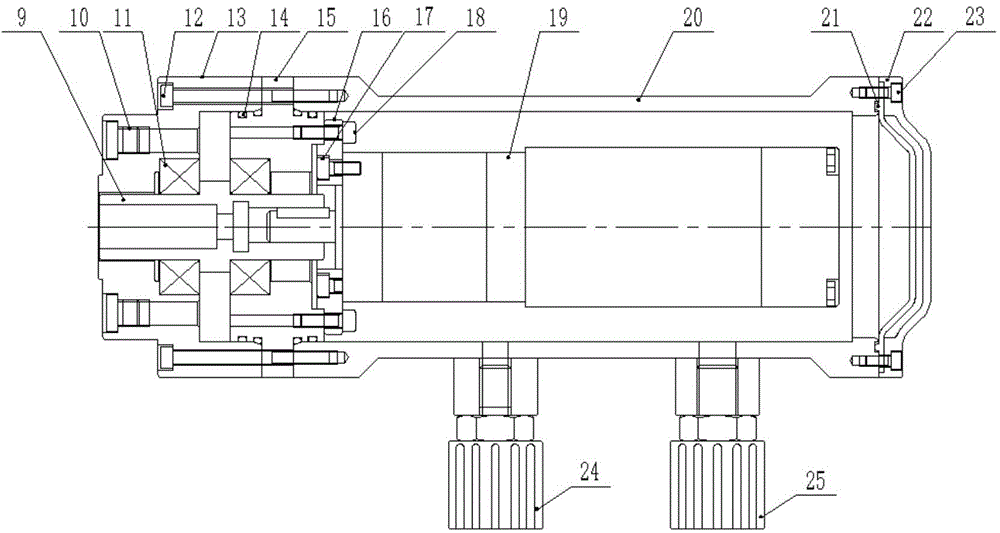

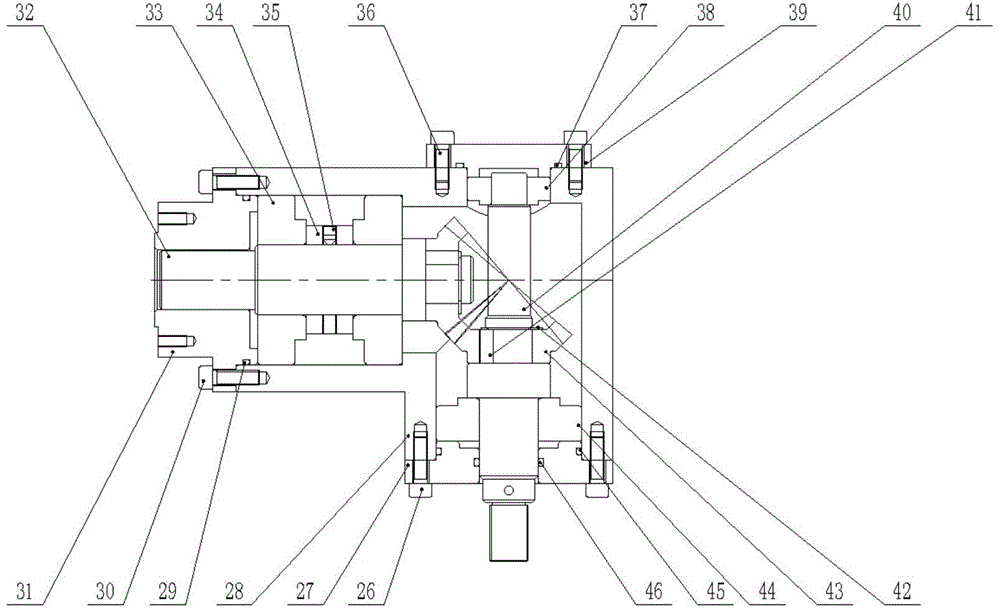

[0018] Such as figure 1 As shown, a small core sampling drilling rig operated by a manned submersible manipulator includes watertight cables 2 and 3, a handle 7, a drilling tool 8, a battery and a control cabin 1, a deep water transmission unit 6, a transmission flexible shaft 5 and Deep water power unit 4, etc.; battery and control cabin 1 are connected with deep water power unit 4 through watertight cables 2 and 3; deep water power unit 4 is connected with deep water transmission unit 6 through transmission flexible shaft 5; deep water transmission unit 6 and drilling tool 8 are connected through thread Connection; the entire drilling rig is installed in the sampling basket at the front of the deep submersible. The drilling tool 8 includes three parts: a drill bit, a coring sleeve and a core tube. The core sleeve adopts a barbed structure and is embedded in the core tube to prevent the core from falling off. Both ends of the core tube are processed with internal threads, and...

Embodiment 2

[0022] The drill bit is made of wear-resistant hard ceramics, the two ends of the core pipe are processed with external threads, the deep water motor 19 is welded on the shell 20 of the deep water power unit 4, and the others are the same as in the first embodiment.

Embodiment 3

[0024] The deep-water transmission unit 6 and the drilling tool 8 are connected by welding to ensure the reliability of the connection, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com