Intelligent on-line test device of power characteristics of carbon dioxide laser devices

A technology of power characteristics and online testing, which is applied in the direction of testing optical performance, etc., can solve the problems of increased manufacturing cost, lack of lasers, and reduced testing efficiency of laser power characteristics, so as to achieve real-time detection and ensure real-time and rapid results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

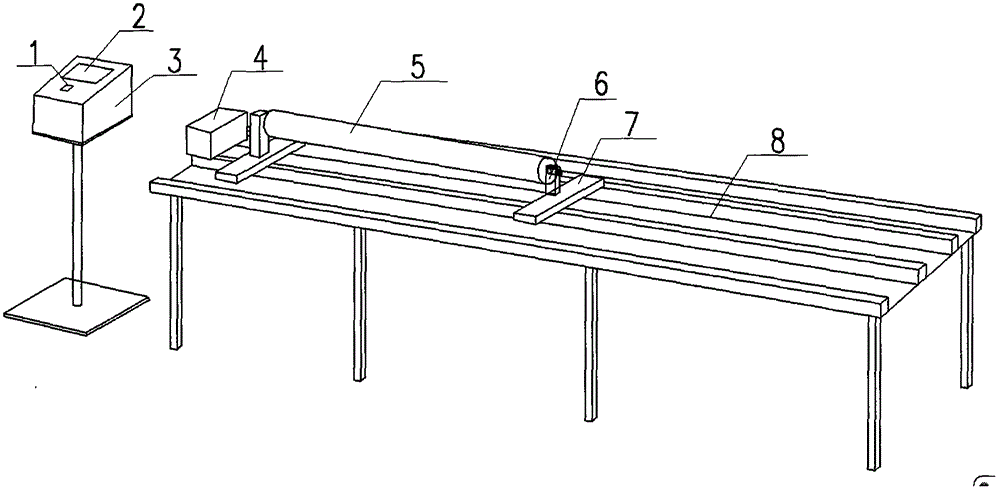

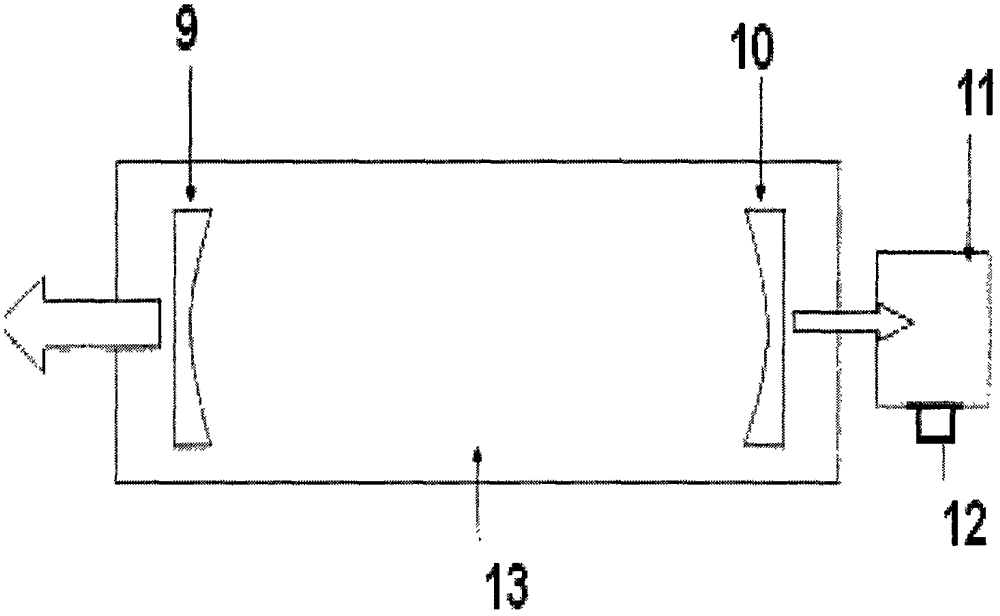

[0009] As shown in the figure, this product includes power supply 1, touch screen 2, control box 3, laser power device 4, laser tube 5, bracket 6, bracket mounting plate 7, optical test bench 8, output mirror 9, medium total mirror 10 , Attenuator 11, detector 12, resonant cavity 13. The whole product is divided into a controller part, a laser sampling device part, and a test part. The controller part is composed of a power supply 1, a touch screen 2, and a control box 3. The test device control system has been developed, including a single-chip microcomputer system, communication interface, analog-to-digital conversion unit, etc. , To achieve object-oriented, automated detection and data processing, to improve the intelligence of the entire test process, to achieve online laser power testing, to ensure the continuity of laser processing, in order to improve the real-time and accuracy of the test; the laser sampling device is partly composed of the output mirror 9. Dielectric t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com