Thin film solid electrolyte amperometric SO 2 Gas sensor and preparation method

A solid electrolyte, gas sensor technology, applied in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve problems such as low operating temperature gas sensors, achieve high precision, realize intelligence, and promote the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

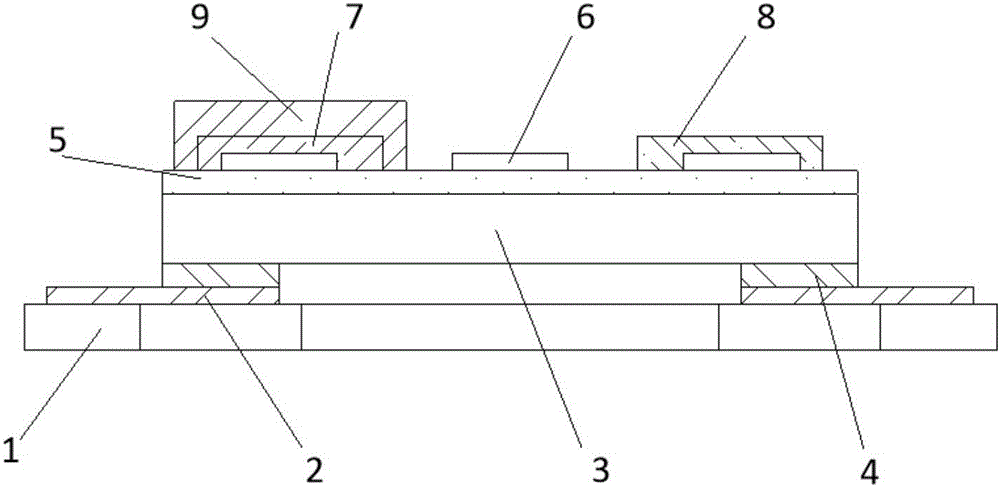

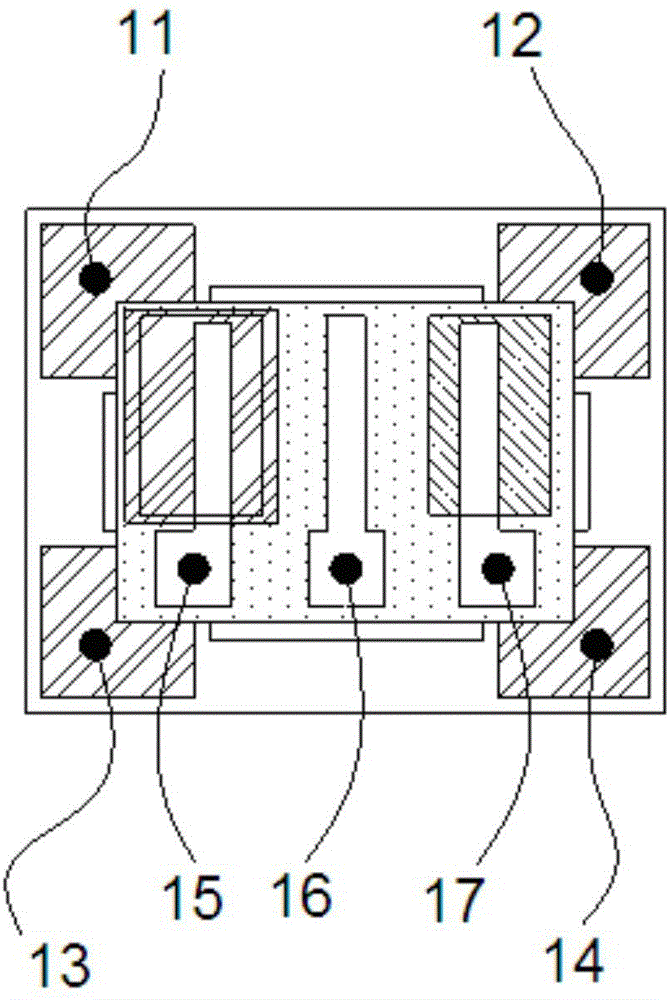

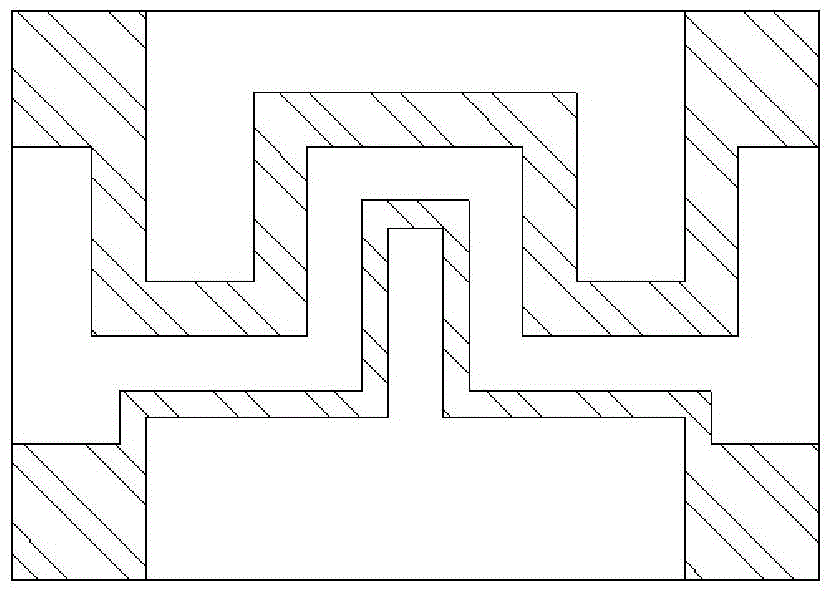

[0032] Such as Figure 1-Figure 4 As shown, a micro amperometric SO based on thin film solid electrolyte 2 Gas sensors, from bottom to top are Al 2 o 3 Susceptor 1, Au thin film on susceptor 2, RuO 2 Temperature control element 4, Al 2 o 3 Substrate 3, Li 3 PO 4 Solid electrolyte layer 5, Au auxiliary electrode 6, Li 2 SO 4 / V 2 o 5 Reaction electrode 7, Li 2 TiO 3 / TiO 2 Reference electrode 8, diffusion barrier layer 9. In this structure, Al 2 o 3 The base 1 adopts a cross hollow structure in the middle ( Figure 4 ), with a thickness of about 10 microns, and Au thin films 2 are sputtered on the upper surfaces of the four corners to facilitate wiring. RuO 2 Temperature control element 4, Al 2 o 3 Substrate 3, Li 3 PO 4 Solid electrolyte layer 5, Au electrode film 6, Li 2 SO 4 / V 2 o 5 Reaction electrode 7, Li 2 TiO 3 / TiO 2 The reference electrode 8 and the diffusion barrier layer 9 form a chip. The temperature control element 4 includes two part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com