Type critical illumination system for extreme ultra-violet lithography

An extreme ultraviolet lithography and lighting system technology, which is applied in the field of quasi-critical lighting systems, can solve the problem of the lack of placement space for the secondary vacuum isolation system and the chip removal system, the compactness of the lighting system and the objective lens system layout, and the increase in the difficulty of component processing and adjustment. The difficulty of calibration and other issues can improve the efficiency of light energy collection, expand the space for light transmission, and reduce the difficulty of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings.

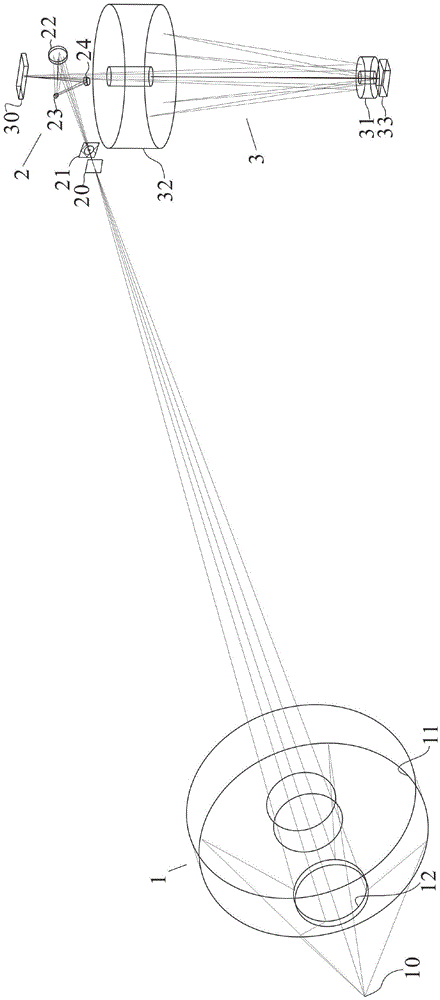

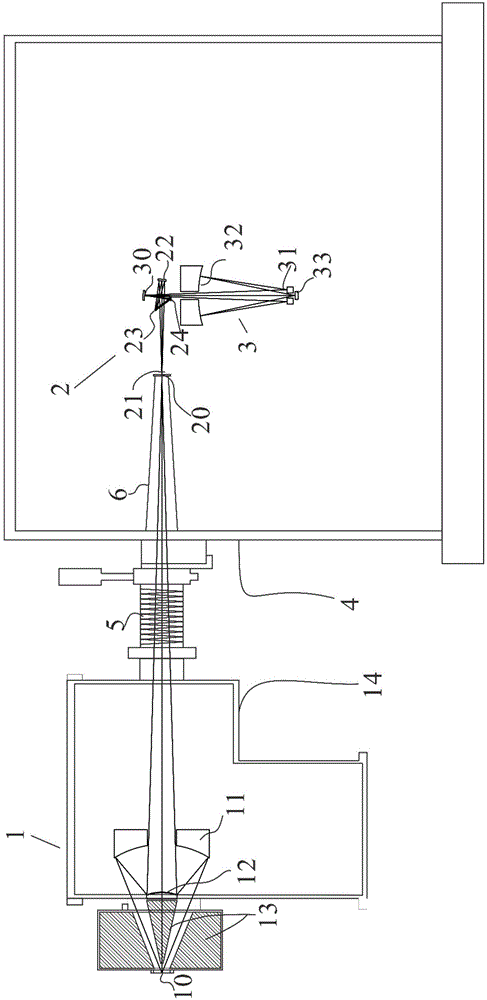

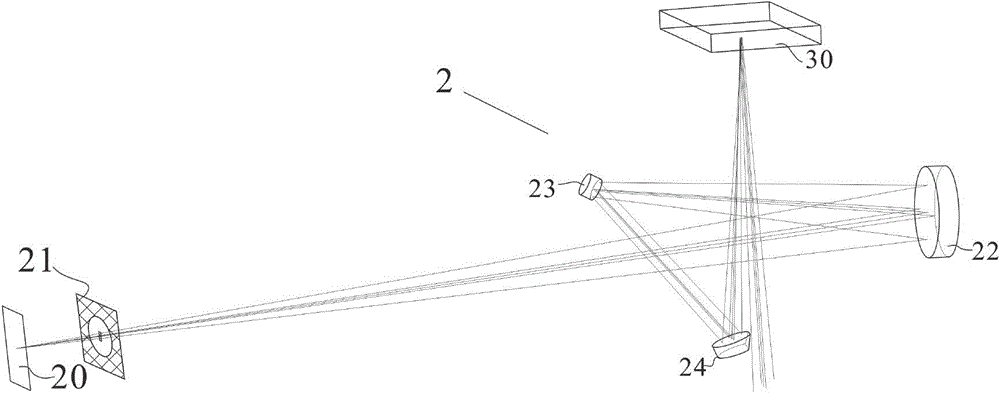

[0029] Such as Figure 1 to Figure 5 As shown, a critical-like lighting system for extreme ultraviolet lithography, the lighting system includes a light-concentrating system 1, a relay system 2, a lithography system, a vacuum box 4, a bellows 5, and a cone 6. The system 1 includes a light source 10, a condensing primary mirror 11, a condensing system secondary mirror 12, a swarf removing system 13, and a condensing system vacuum box 14. The swarf removing system 13 is arranged along the optical path on the rotational symmetry axis of the light cone of the light source 10 ; The condensing system secondary mirror 12 and the condensing primary mirror 11 are sequentially located behind the anti-dandruff system 13, the light source 10 is a wide-spectrum DPP light source, and the condensing system secondary mirror 12 and the condensing primary mirror 11 together form Schwartz· In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com