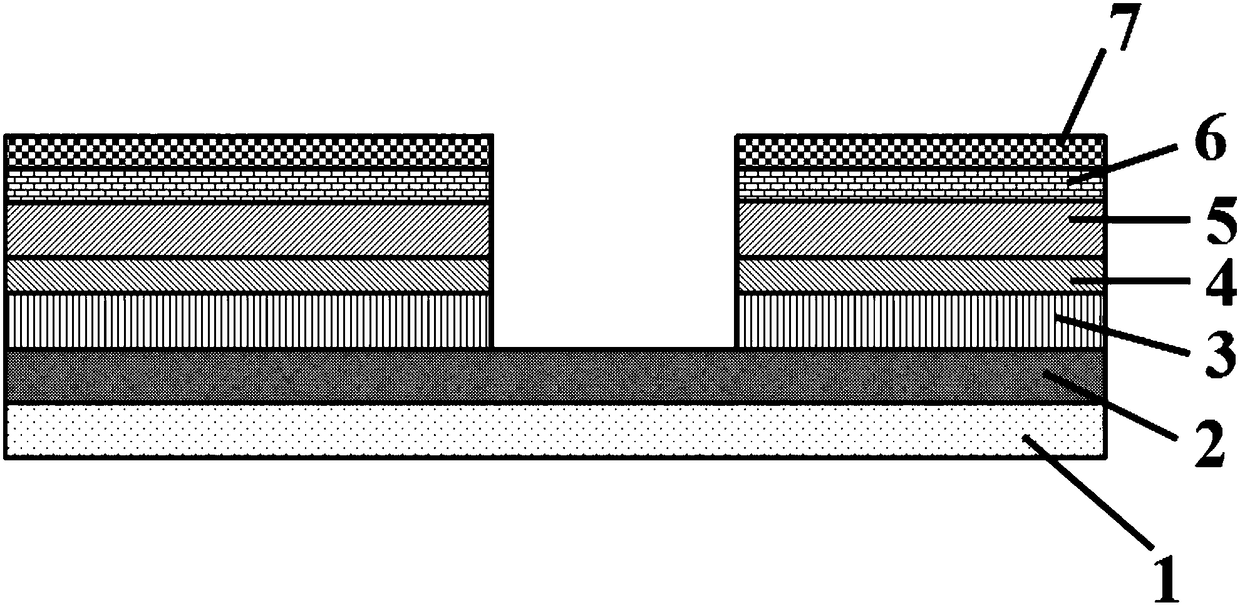

High-molecular-based phototactic perovskite solar cell and preparation method thereof

A solar cell, polymer-based technology, applied in the field of solar cells, can solve problems such as unfavorable miniaturization, adaptive intelligent application, energy consumption, etc., to improve photoelectric conversion efficiency, energy utilization efficiency, and light energy collection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

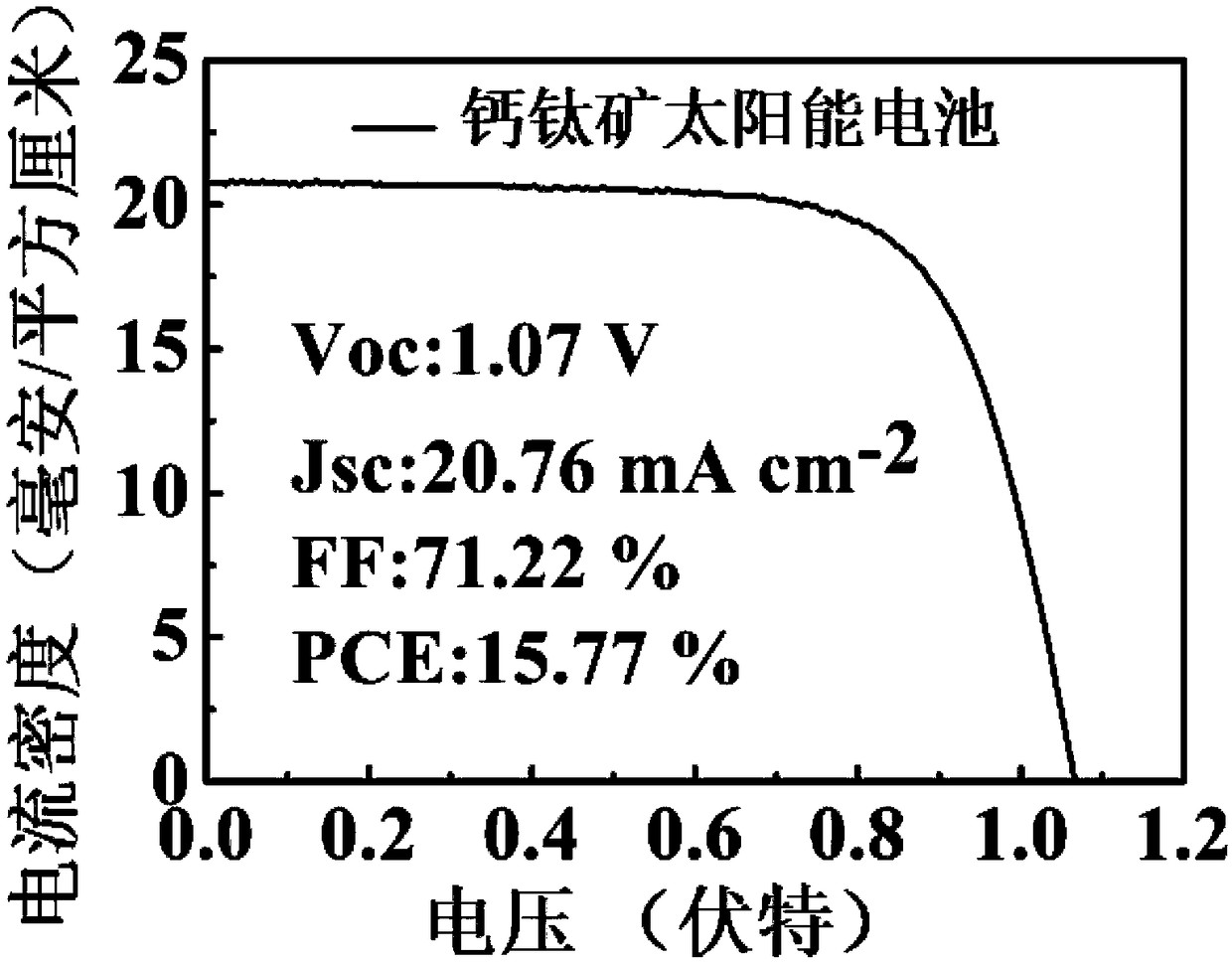

Examples

Embodiment 1

[0031] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 500 μm and a transmittance of 85%; the electron transport layer is made of inorganic material TiO 2 . Magnetically stir the mixed solution of 18ml ethanol, 1.8ml n-butyl titanate and 0.38ml diethanolamine at 40°C for 2h, let it stand for 24h, then spin-coat the mixed solution onto the surface of ITO-PET, and immediately coat the film Transfer to a pre-heated 150°C hot stage and heat for 180min to obtain an electron transport layer TiO with a thickness of 3nm 2 ; Wherein the spin coating speed is 3000rpm, and the time is 45s.

[0032] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, the film is ...

Embodiment 2

[0039] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 1 μm and a transmittance of 95%; the electron transport layer is made of inorganic material SnO 2 . The precursor SnCl 2 2H 2 O was dissolved in ethanol at a concentration of 0.1 mg / ml, and then the solution was spin-coated onto the surface of ITO-PET. Immediately after the spin-coating, the film was transferred to a pre-heated 150°C hot stage and heated for 60 minutes to obtain an electron transport layer with a thickness of 40nm. Layer SnO 2 ; Wherein the spin coating speed is 2500rpm, and the time is 45s.

[0040] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, transfer the film to a pre-...

Embodiment 3

[0047] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 350 μm and a transmittance of 90%; the electron transport layer is made of inorganic material SnO 2 . The precursor SnCl 2 2H 2 O was dissolved in ethanol at a concentration of 0.1 mg / ml, and then the solution was spin-coated on the surface of ITO-PET. Immediately after the spin-coating, the film was transferred to a pre-heated 150°C hot stage and heated for 60 min to obtain an electron transport film with a thickness of 60 nm. Layer SnO 2 ; Wherein the spin coating speed is 2000rpm, and the time is 45s.

[0048] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, transfer the film to a pre-heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com