A polymer-based phototropic perovskite solar cell and its preparation method

A solar cell and polymer-based technology, applied in the field of solar cells, can solve the problems of unfavorable miniaturization, self-adaptive intelligent application, energy consumption, etc., and achieve the improvement of photoelectric conversion efficiency, energy utilization efficiency, important energy-saving significance and The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

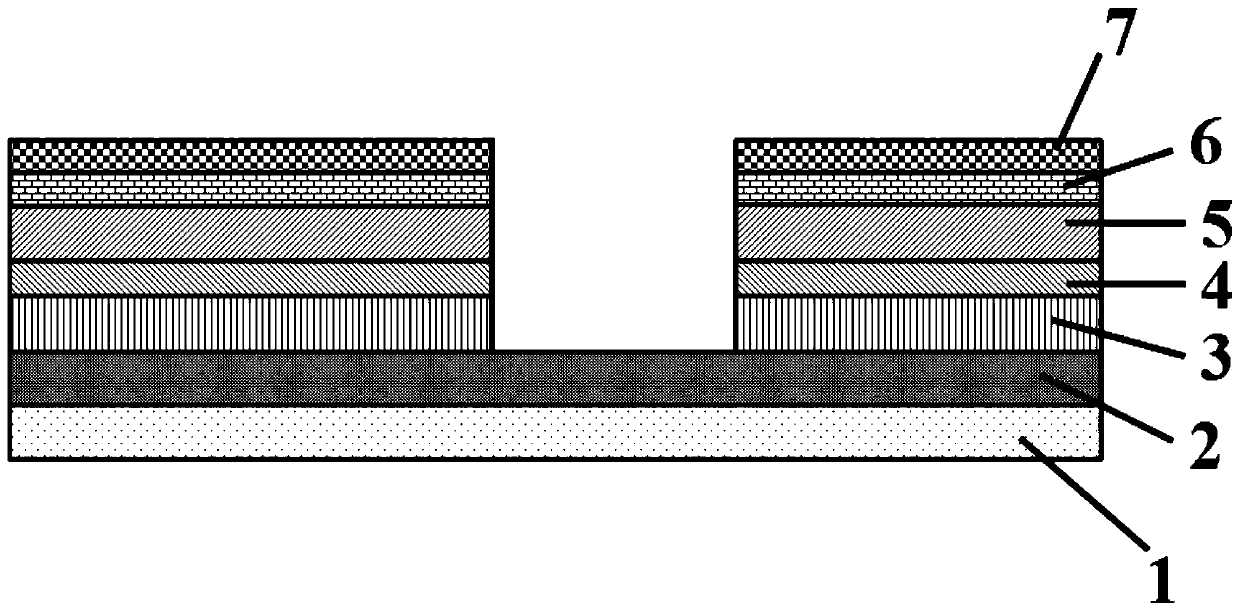

[0031] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 500 μm and a transmittance of 85%; the electron transport layer is made of inorganic material TiO 2 . Magnetically stir the mixed solution of 18ml ethanol, 1.8ml n-butyl titanate and 0.38ml diethanolamine at 40°C for 2h, let it stand for 24h, and then spin coat the mixed solution onto the surface of ITO-PET. Transfer to a pre-heated 150°C hot stage and heat for 180min to obtain an electron transport layer TiO with a thickness of 3nm 2 ; Wherein the spin coating speed is 3000rpm, and the time is 45s.

[0032] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, transfer the film to a pre-heated 70°C...

Embodiment 2

[0039] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 1 μm and a transmittance of 95%; the electron transport layer is made of inorganic material SnO 2 . The precursor SnCl 2 2H 2 O was dissolved in ethanol at a concentration of 0.1 mg / ml, and then the solution was spin-coated onto the surface of ITO-PET. Immediately after the spin-coating, the film was transferred to a pre-heated 150°C hot stage and heated for 60 minutes to obtain an electron transport layer with a thickness of 40nm. Layer SnO 2 ; Wherein the spin coating speed is 2500rpm, and the time is 45s.

[0040] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, transfer the film to a pre-...

Embodiment 3

[0047] (1) Prepare the electron transport layer on the working electrode: the working electrode is made of ITO-PET with a thickness of 350 μm and a transmittance of 90%; the electron transport layer is made of inorganic material SnO 2 . The precursor SnCl 2 2H 2 O was dissolved in ethanol at a concentration of 0.1 mg / ml, and then the solution was spin-coated on the surface of ITO-PET. Immediately after the spin-coating, the film was transferred to a pre-heated 150°C hot stage and heated for 60 min to obtain an electron transport film with a thickness of 60 nm. Layer SnO 2 ; Wherein the spin coating speed is 2000rpm, and the time is 45s.

[0048] (2) Preparation of light-absorbing layer on the electron transport layer: the perovskite precursor PbI 2 Dissolve in DMF according to the concentration of 463 mg / ml, and spin-coat the obtained solution on the surface of the above-mentioned electron transport layer. Immediately after the spin-coating, transfer the film to a pre-heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com