OLED device with optical resonance layer, manufacturing method of OLED device and displayer

An optical resonance and device technology, applied in the field of OLED display, can solve the problems of insignificant optical band extraction effect, difficult process, unsatisfactory solution, etc., and achieves the effect of good chromaticity, low display quality, and reduced process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the OLED device with the optical resonance layer of the present invention comprises:

[0038] Clean the substrate and prepare a TFT array on the substrate;

[0039] Preparation of color filter film;

[0040] Prepare a flat layer on the color filter film;

[0041] preparing an optical resonant layer on the flat layer in the region corresponding to the G sub-pixel;

[0042] preparing a transparent electrode on the optical resonant layer;

[0043] Preparation of white light OLED devices;

[0044] Encapsulating and completing the preparation of the display device.

[0045] Wherein, the step of preparing the optical resonance layer in the region corresponding to the G sub-pixel includes:

[0046] preparing a first dielectric layer with a thickness of 10-150 nm;

[0047] A second dielectric layer is prepared on the first dielectric layer with a thickness of 0-300nm.

no. 1 approach

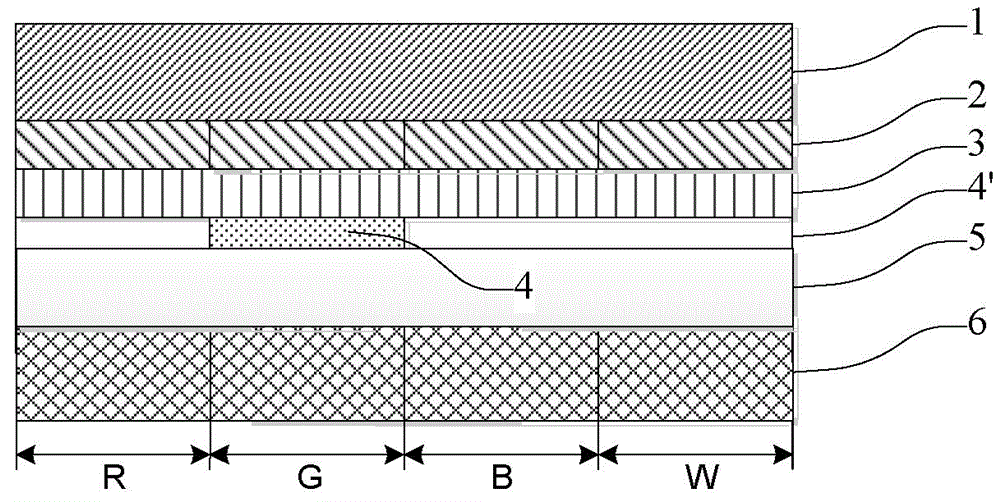

[0050] Such as figure 1 As shown, the OLED device with an optical resonant layer in this embodiment includes a substrate, a TFT array (not shown in the figure) is arranged on the substrate, a color filter film 6 is provided on the TFT array, and the color filter film 6 is divided into R , G, B, and W four colors to filter the white light emitted by the white OLED to form R sub-pixels, G sub-pixels, B sub-pixels and W sub-pixels. According to the needs, the R sub-pixel, G sub-pixel, B sub-pixel and W sub-pixel emit light of different intensities, and the light emitted by the R sub-pixel, G sub-pixel, B sub-pixel and W sub-pixel is mixed to obtain the required color. Display in color. After a plurality of OLED devices are arranged according to a certain rule (such as an array), they cooperate with other components such as a casing to form the display of the present invention.

[0051] figure 1In the illustrated embodiment, a planar layer 5 is provided on the color filter film...

no. 2 approach

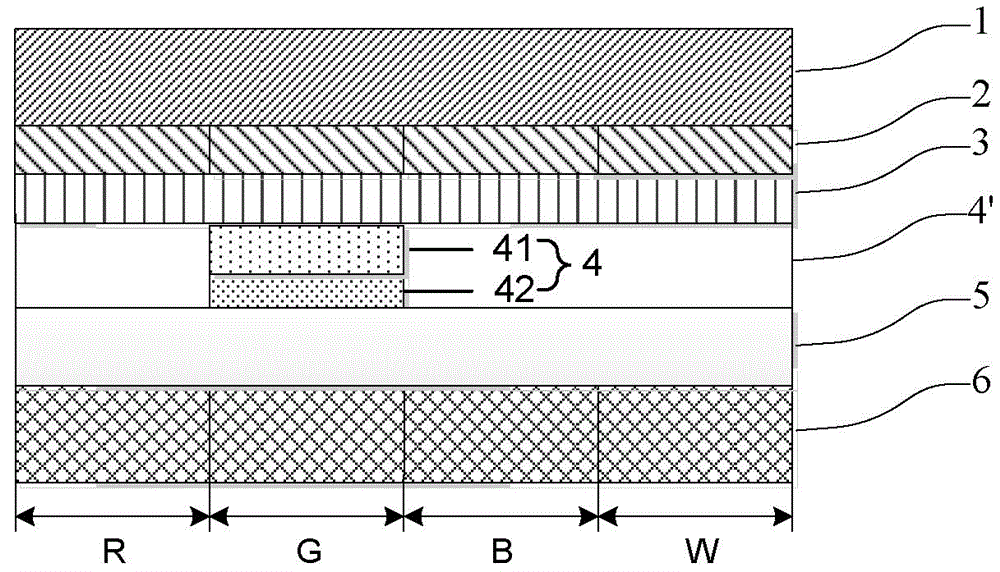

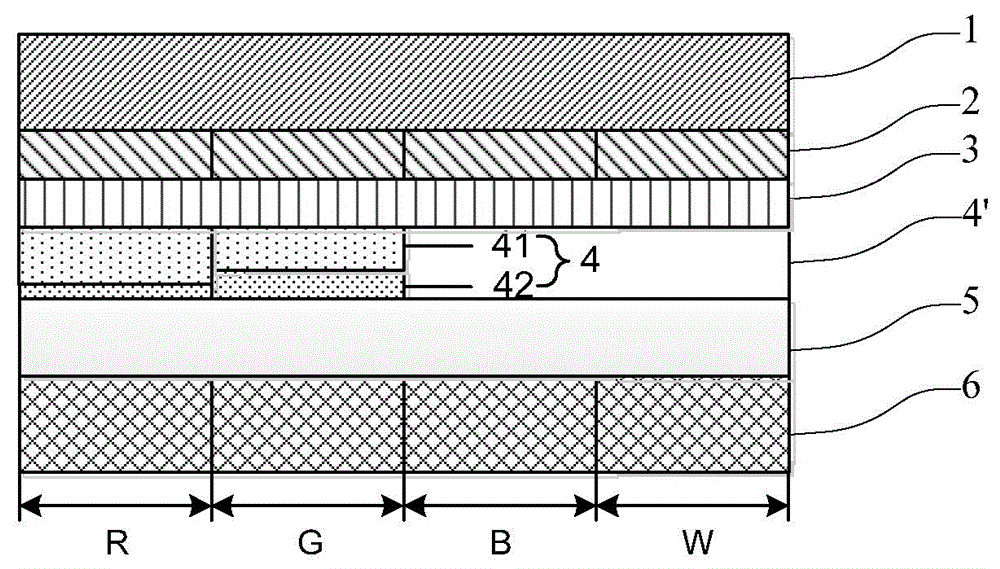

[0061] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the optical resonant layer 4 has a double-layer dielectric structure. That is, the optical resonance layer 4 in the second embodiment includes the first dielectric layer 42 and the second dielectric layer 41 . The preparation method of the OLED device of the second embodiment is as follows:

[0062] 1. Clean the substrate and prepare a TFT array on the substrate;

[0063] 2. Prepare color filter film 6;

[0064] 3. Prepare a flat layer 5 on the color filter film 6;

[0065] 4. Prepare the first dielectric layer 42 in the area corresponding to the G sub-pixel on the flat layer 5, and prepare the second dielectric layer 41 on the first dielectric layer 42 to complete the preparation of the optical resonant layer 4 of the double dielectric layer structure; Area preparation filling layer 4';

[0066] 5. Prepare a transparent electrode 3 on the optical resonant layer 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com