Wet type water film electrode electric-coagulation device

A technology of condenser and water film, applied in the direction of electrode structure, external electrostatic separator, electrostatic separation, etc., can solve the problems of easy generation of back corona and secondary dust, small practical application possibility, complex design, etc., to achieve Improve coagulation efficiency, good coagulation effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

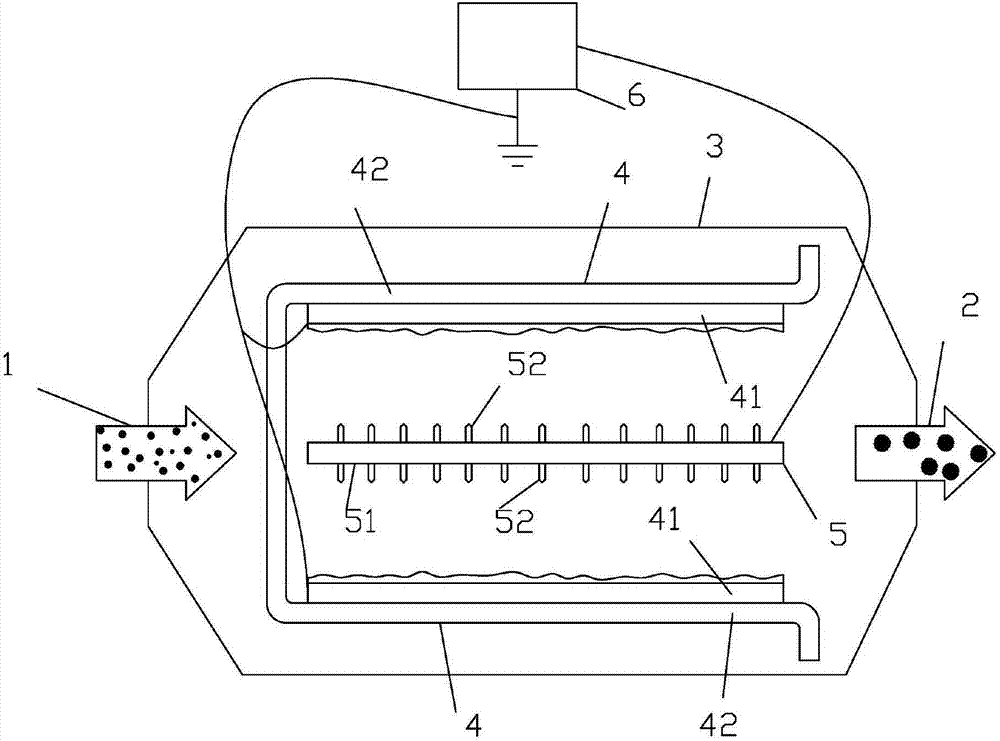

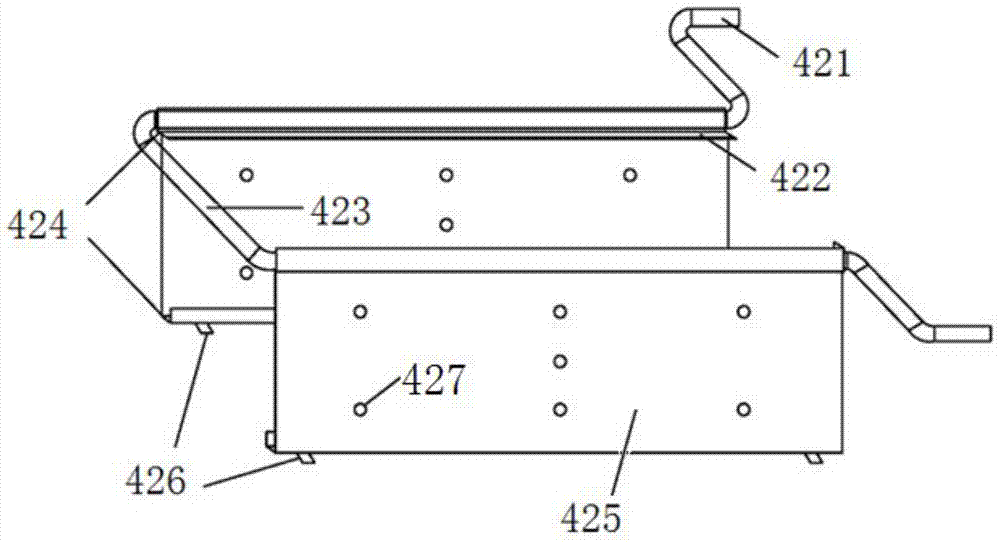

[0027] Design an electrocoagulator. The electrocoagulator consists of a housing 3, two grounding plates 41 symmetrically arranged in the housing 3, a water distributor 42 fixed to the grounding plates 41, and a high-voltage electrode 5, which are arranged symmetrically. Between the upper and lower grounding electrodes 41, and the different polar distances between the high-voltage pole plate 51 and the grounding pole plate 41 are equal; the high-voltage pole plate 51 is connected to the high-voltage pole of the high-voltage AC power supply 6, and the two grounding pole plates 41 are both grounded The electric field is supplied by the high-voltage AC power supply 6; the water distributor 42 on the ground plate is connected to the water pump, and the side of the support plate 425 on the water distributor 42 is provided with 7 fastening bolt holes 427.

[0028] The specific structural parameters of the electrocoagulation combiner are designed as follows: the shell 3 is a cuboid, t...

Embodiment 2

[0031] The structural composition of the electrocoagulator is the same as in Embodiment 1. However, there is a grounding thorn on the grounding plate, and the specific structural parameters are designed as:

[0032] The shell 3 is a cuboid, with an air inlet 1 and an air outlet 2 axially opened, the dimensions of the high-voltage pole plate 51 and the grounding pole plate 41 are both 450×800mm, and the material of the grounding pole plate is a metal plate, the high-voltage pole plate 51 and the grounding pole plate The distance between 41 is 200mm, the length of the high-voltage burrs 51 is 20mm, the grounding plate 41 is provided with grounding burrs, the length of the grounding burrs is 20mm, the diameters of the high-voltage burrs 52 and the grounding burrs are 3mm, and the high-voltage The vertical and horizontal distances of the thorns 52 are both 30mm, the vertical and horizontal distances of the grounded thorns are 30mm, the rated output voltage of the high-voltage AC p...

Embodiment 3

[0035] The structural composition of the electrocoagulator is the same as in Embodiment 1. But the specific structural parameters are designed as:

[0036] The shell 3 is a rectangular parallelepiped, and the air inlet 1 and the air outlet 2 are axially opened. The dimensions of the high-voltage pole plate 51 and the grounding pole plate 41 are both 600×960mm. The groove depth is 6mm, the groove width is 3mm, and the groove spacing is 2mm. The distance between the high-voltage pole plate 51 and the grounding pole plate 41 is 200mm. The length of the high-voltage thorn 51 is 20mm. , and the horizontal spacing are all 50 mm, the rated output voltage of the high-voltage AC power supply 6 is 35 kV, and the frequency is 10 Hz.

[0037] According to the experiment, the wind speed at the inlet of the flue gas is 1.8m / s, and the powder concentration is 2.00g / m 3 , under the condition of influent flow rate of 250L / h, the volume occupancy rate of dust with a particle size of less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com