Tower-type dissolved air air-flotation machine

A dissolved air flotation machine and tower-type technology, which is applied in flotation water/sewage treatment, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of poor adhesion of microbubbles and particles The flocs and foam flocs cannot be floated and separated well, and the contact time between air bubbles and suspended solids is short, so as to achieve the effect of compact structure, small footprint and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

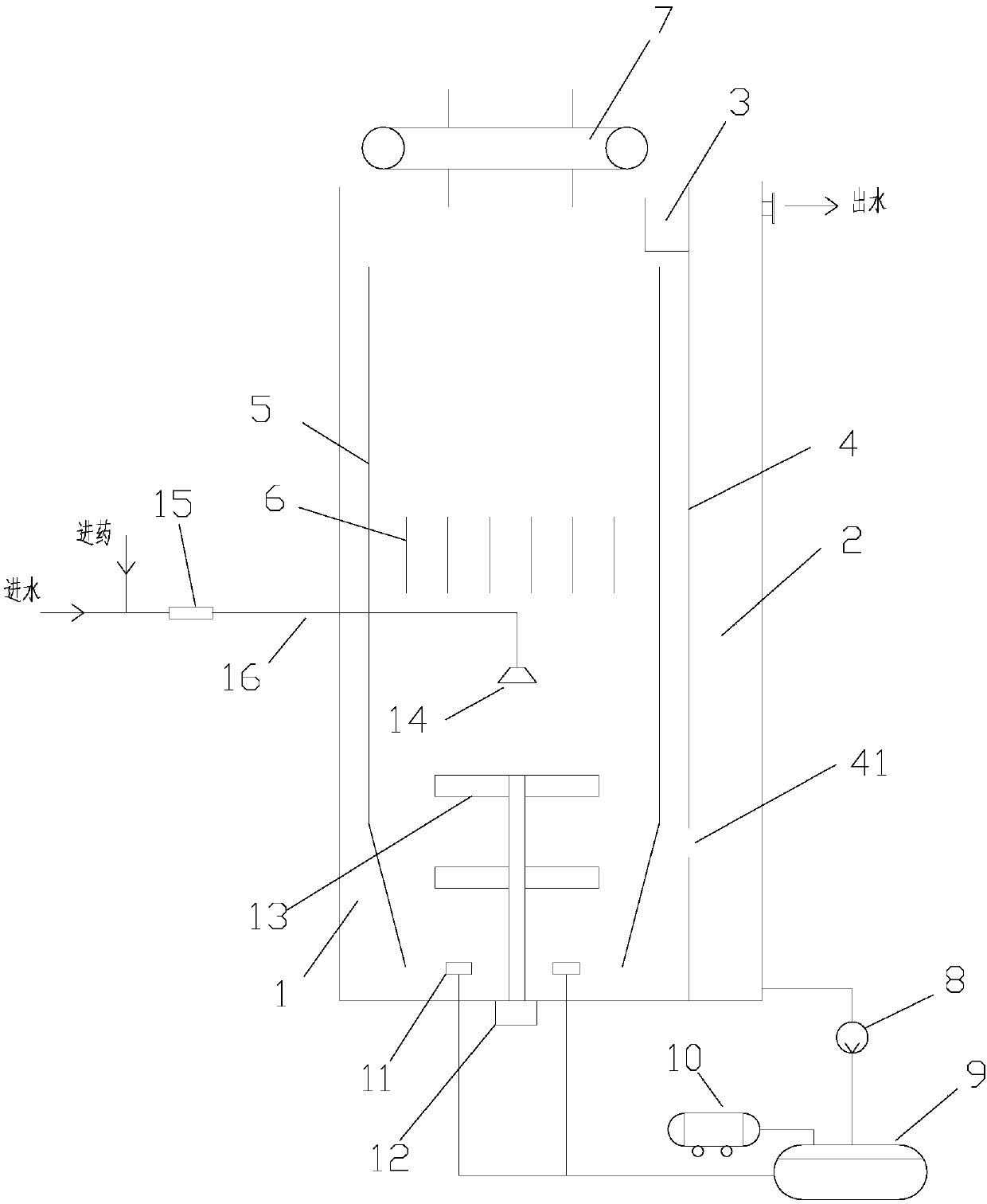

[0021] Such as figure 1 As shown, the present invention provides a high-tower dissolved air flotation machine including an air flotation reaction tank 1, a clear water tank 2, a scum tank 3, a scum scraping device 7, a dissolved air system, a bubble releaser 11, and a static mixer 15 , stirring motor 12, agitator 13, nozzle 14, water inlet pipe 16, water inlet and dosing port; described air flotation reaction pool 1 and clear water pool 2 are separated by dividing plate 4; Described dividing plate 4 is provided with clear water Holes 41; the clear water tank 2 is provided with a water outlet; the scum tank 3 is arranged above the air flotation reaction tank 1; the scraping device 7 is positioned above the air flotation reaction tank 1, and the scraping device 7 includes a chain, Two sprockets and multiple scum scrapers are connected by a chain, and multiple scum scrapers are fixed on the chain, and the sprockets drive the scum scrapers on the chain to scrape the scum in the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com