Eight-station fixed-point and fixed-position rotary cleaning machine

A technology for positioning, rotating and cleaning machines, which is applied to dryers, cleaning methods and utensils, and cleaning methods using liquids. It can solve problems such as low efficiency, low yield rate, and low cleaning capacity, and achieve optimal equipment structure, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

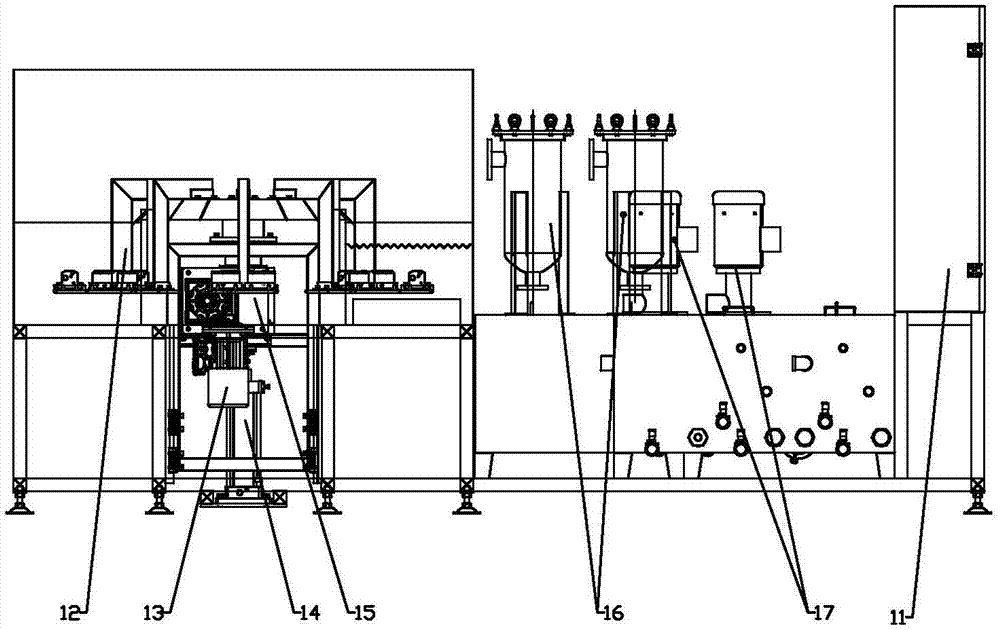

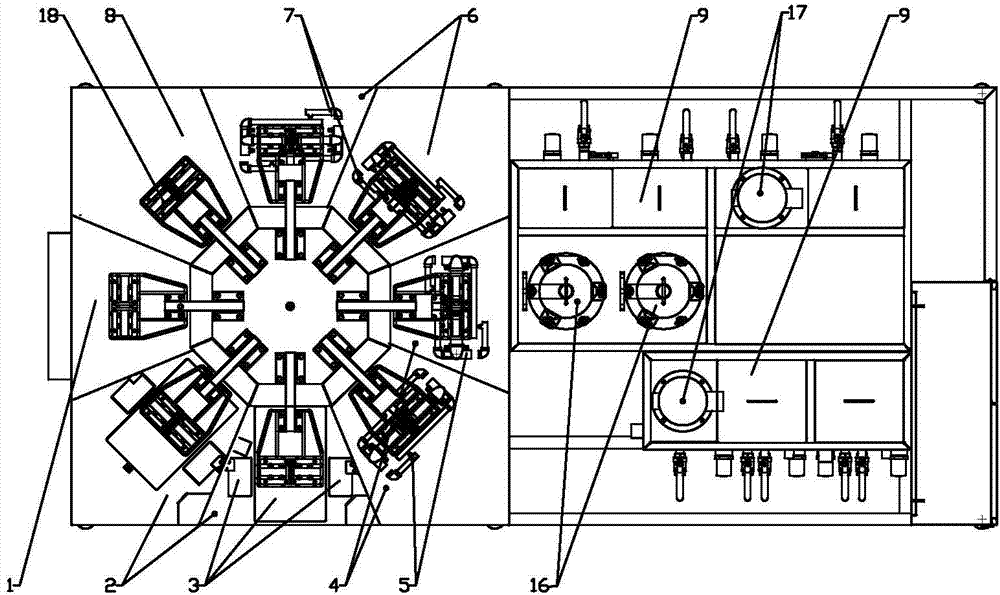

[0028] refer to figure 1 and 2 , the present invention provides an eight-station fixed-point positioning rotary cleaning machine, including a frame, a control electric cabinet 11, and a rotary lifting mechanism and a station platform arranged on the frame; the rotary lifting mechanism includes a reducer 13 and a lifting cylinder 14, The rotating mechanical arm 12 driven to rotate by the reducer 13 and driven up and down by the lifting cylinder 14 is provided with a high-precision divider 15 between the rotating shaft of the rotating mechanical arm 12 and the reducer 13; Eight supporting arms are equally divided, each supporting arm is provided with a fixture 18; eight stations forming a circle are arranged on the station platform, and each station corresponds to the fixture 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com