Automotive lighting lamp cover embedding device

A lighting lamp and lamp cover technology, which is applied in the field of automotive lighting lamp cover embedding devices, can solve problems such as fixed chucks that cannot meet multi-standard molds, wrong up and down forward and reverse conveying of bolts, and bolts that cannot be fixed at a fixed position, etc., to achieve The effect of reducing chuck changing time, reducing quality cost, and reducing the difficulty of chuck changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

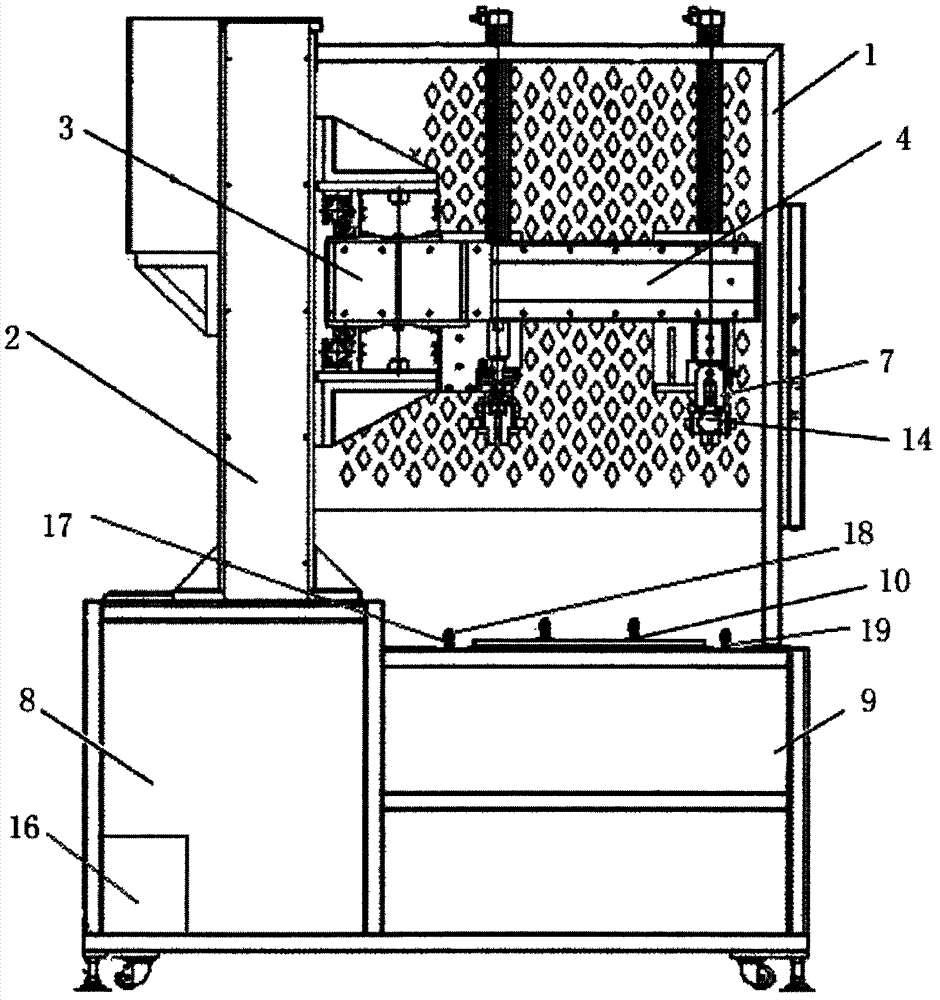

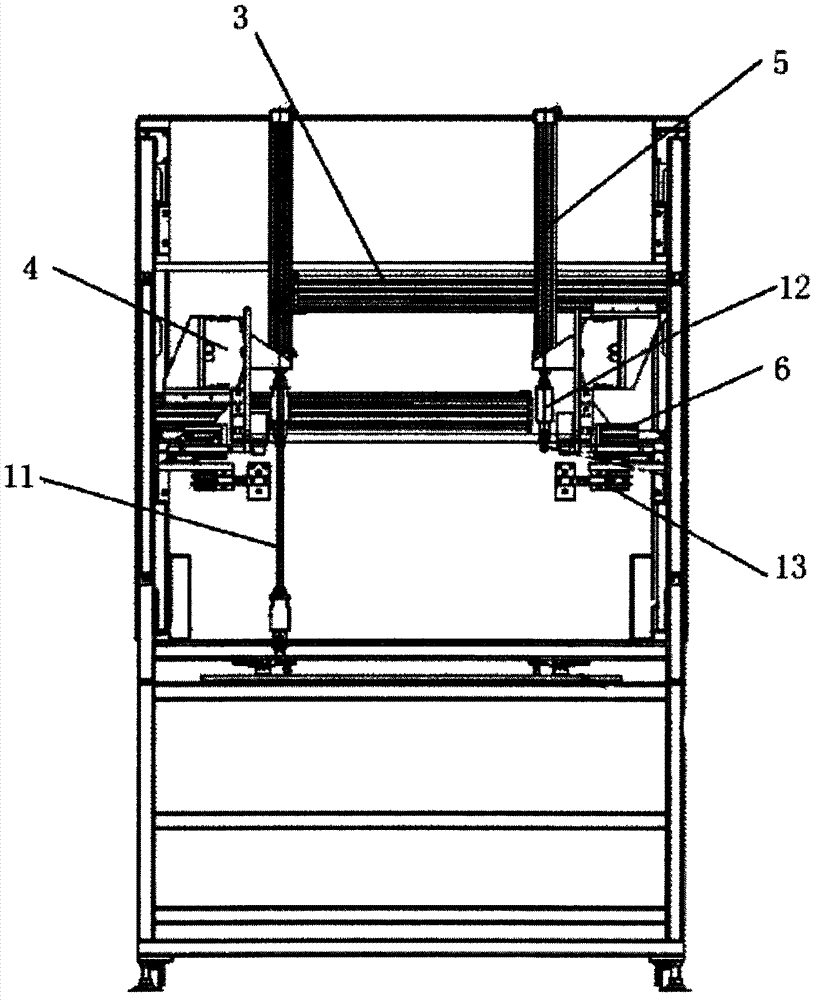

[0013] See figure 1 and figure 2 As shown, a lamp cover embedding device for automobile lighting lamps includes a frame 1, a slide table column 2 is provided at one end of the frame 1, and an X-axis slide table 3 is arranged laterally on the slide table column 2, The X-axis slide table 3 is provided with a Y-axis slide table 4 for supporting the thermally buried cylinder 5, and the outside of the thermally buried cylinder 5 is equipped with a vertical feeding mechanism 6 that automatically provides bolts. The thermally buried pneumatic rod 11 The top is provided with a screw suction head 12 for sucking up the bolts and a collet 13 for clamping the bolts, and a proximity sensor 14 and a temperature sensor 7 are respectively connected directly below the collet 13, and the temperature sensor 7 is connected to the cut-off current. The servo motor 16 is connected. A positioning device 17 is provided on the working base 10 , and the collet 13 is sleeved on the top of the screw su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com