Novel dried bean curd automatic blank preparing production line

A technology for automatic production of dried tofu, applied in the field of new automatic production line of dried tofu, can solve the problems of destroying the uniformity of the thickness of the tofu brain, the magnetic control of the cylinder magnetic ring and the water stop, the large area of the return frame and the large vibration, etc. Achieve the effect of improving stability and product quality, increasing production capacity, and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

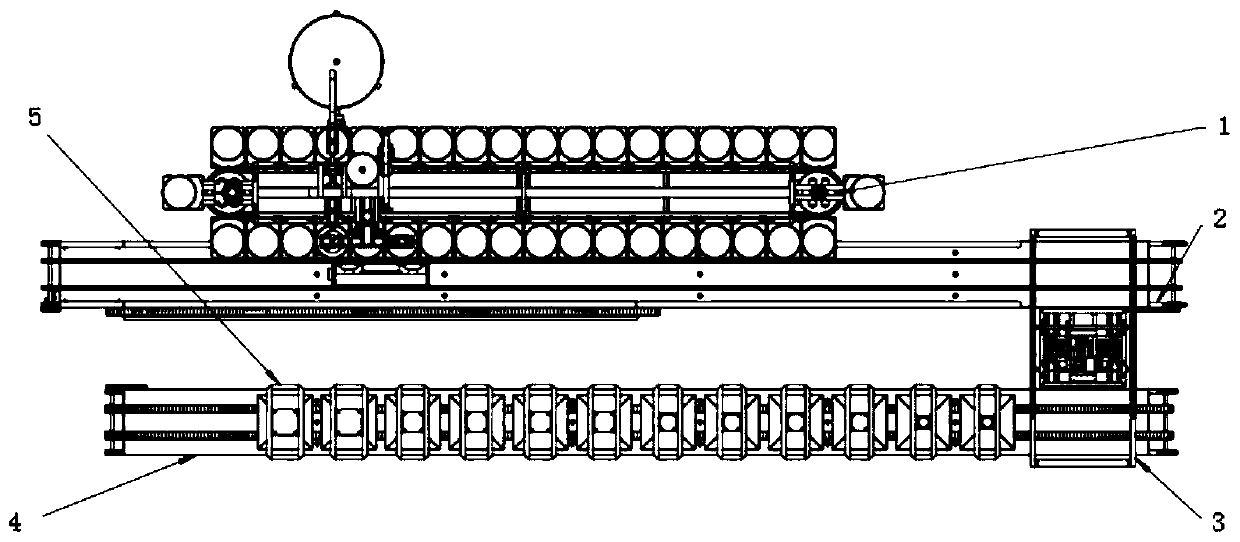

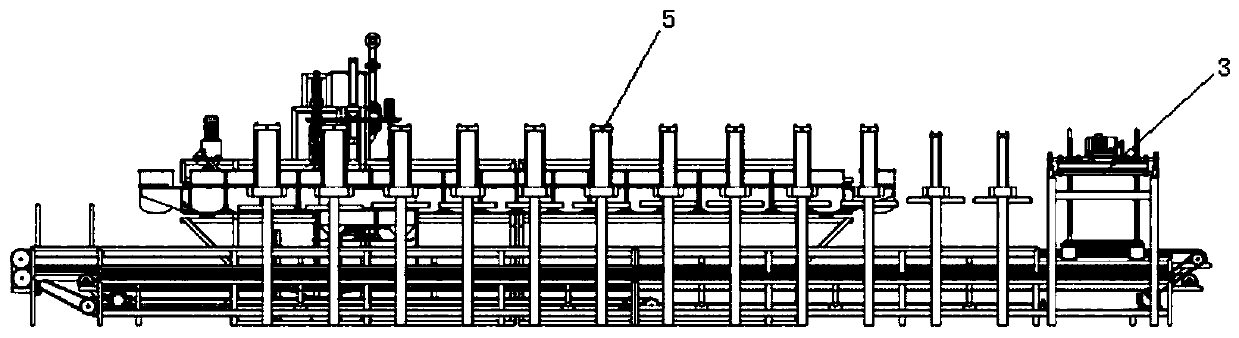

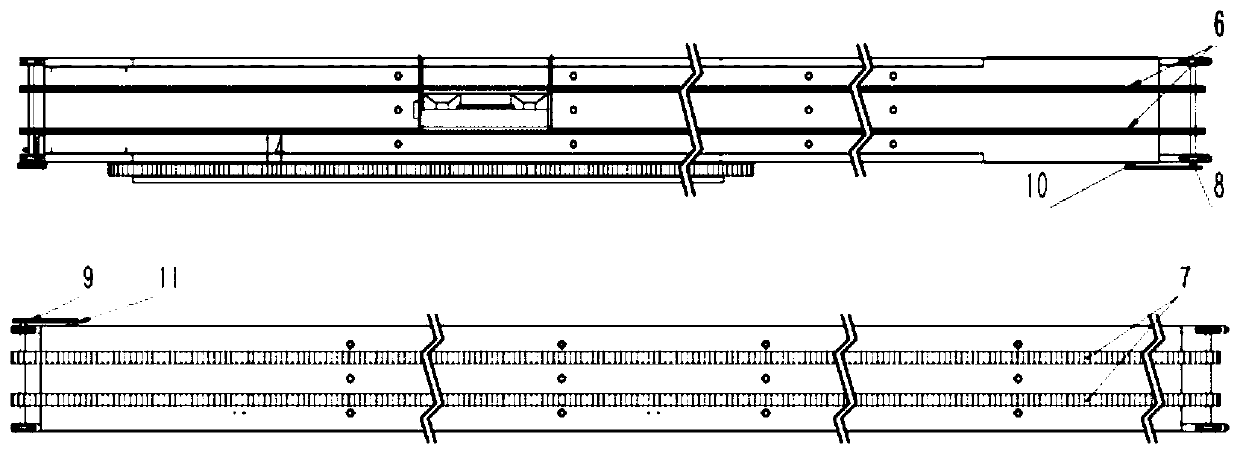

[0026] Reference Figure 1-Figure 8 , A new type of dried bean curd automatic billet production line, including a conveyor line 2 and a pressing line 4 arranged side by side, and a PLC controller for controlling the conveyor line 2 and the pressing line 4. The conveyor line 2 is equipped with a computer system 1 for conveying The front end of the line 2 is provided with an adjustable lifting baffle 12, the tail end of the conveying line 2 is connected to the pressing line 4 by a three-axis grasping robot 3, and the conveying line 4 is passed through the first motor output shaft 10, the first conveying sprocket 8 and Conveyor chain 6 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com