Generator stator loading structure device

A generator stator and load-carrying end technology, applied in the direction of transportation and packaging, transportation of passenger cars, trucks, etc., can solve problems such as hidden dangers of accidents, endangering transportation safety, difficulty in meeting the transportation needs of generator stators, etc., to improve safety and reduce structural weight , to avoid the effect of excessive structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

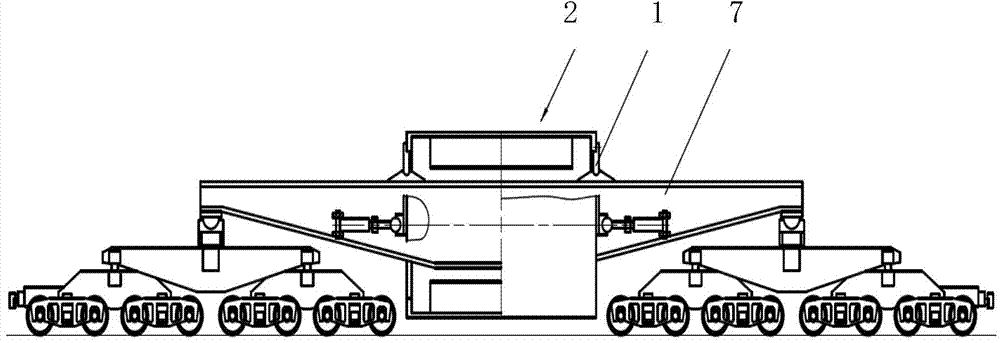

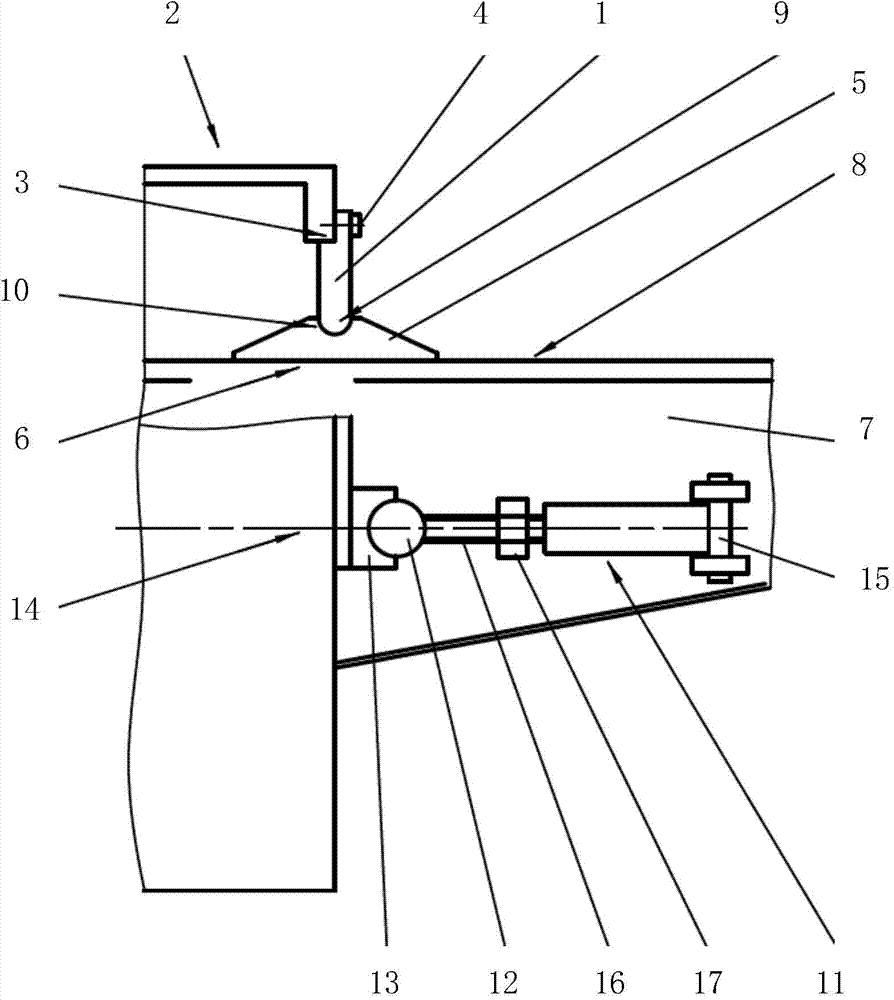

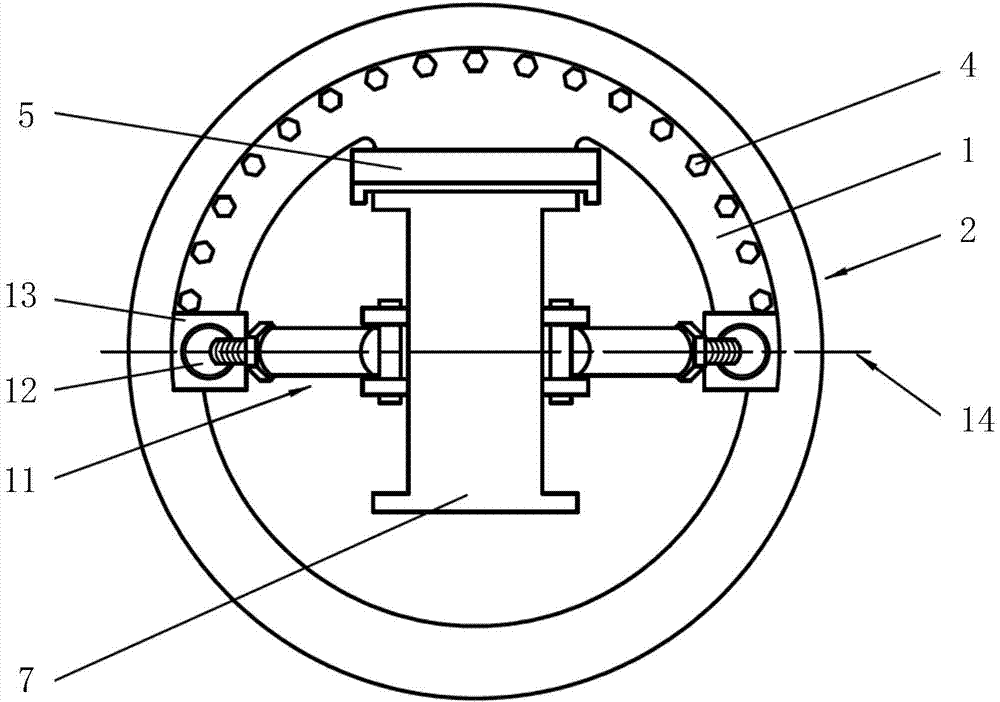

[0011] figure 1 It is a loading arm transport vehicle transporting generator stator loading structure device, figure 2 For a partial enlargement, image 3 It is a cross-sectional schematic diagram, there is a load-bearing notch 3 between the load-bearing end plate 1 and the generator stator 2, the load-bearing end plate 1 is fixed on the generator stator 2 by the closing bolt 4; the limited flexible tread 6 of the load-bearing saddle 5 and the load-bearing The bearing surface 8 of the arm 7 is in contact, and the convex hinge shaft 9 of the bearing end plate 1 falls in the hinge shaft socket 10 of the bearing saddle 5; The tread surface 6 has a symmetrical trapezoidal cross-sectional structure; the ball head 12 of the longitudinal stop swing arm 11 is in contact with the stop ball socket 13 of the bearing end plate 1; The stop ball socket 13 is located on both sides of the horizontal centerline 14; the longitudinal stop swing arm 11 is connected to the carrying arm 7 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com