Airbag type deceleration top and deceleration method

A technology of deceleration tops and airbags, applied in the direction of track brakes, railway car body parts, transportation and packaging, etc., can solve the problems of reduced service life, increased maintenance costs, and normal exhaust, and achieve the effect of eliminating water ingress and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

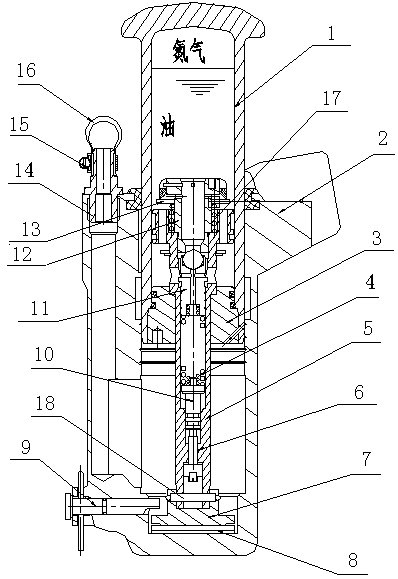

[0015] An airbag-type decelerator, which consists of: the speed valve plate 13 connected to the piston rod 5 in the decelerator slide cylinder 1, the high-pressure upper chamber formed by the decelerator slide cylinder and the piston rod, The left side of the housing has an exhaust pipeline connected to the air bag 16, and the housing has a return air pipeline connected to the air bag. The lower chamber of the sliding cylinder of the decelerator is connected to the hydraulic oil pump, and the hydraulic oil pipeline is equipped with a return valve. The sliding oil cylinder of the deceleration top is connected with the helium pump body 2.

Embodiment 2

[0017] According to the air bag-type speed bumper described in Embodiment 1, the exhaust pipe has an exhaust pipe seat 14 on which the air bag 16 is fixed by a throat hoop 15, and the casing The bottom has an adjustment pad 8, and the adjustment pad has a stopper seat 7, and the stopper seat is fixedly connected by a stopper pin 9, and the described stopper seat is connected with the piston rod 5 through a cylindrical pin 18, and the piston A sealing cover 3 is sheathed on the outside of the rod, and the sliding oil cylinder 1 is sheathed on the outer cover of the sealing cover.

Embodiment 3

[0019] According to the airbag type decelerator described in Embodiment 1, the interior of the piston rod is hollow, the base of the piston rod has a pressure regulating screw 6, and the pressure regulating screw has a spring seat 10, and the spring seat There is a spring 4 on it, and the spring has a pressure valve stem 11, and the upper end of the pressure valve stem is connected with the pressure valve seat 12 through a speed valve plate 13 and a speed spring 17, and the speed valve plate and the speed spring are sequentially set on the speed valve seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com