Active heave compensation control system and active heave compensation control method of marine ship-borne AC variable-frequency winch

A technology of AC frequency conversion and heave compensation, applied in the direction of hoisting device, spring mechanism, etc., can solve problems such as complex structure, and achieve the effect of simple control process, improved service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

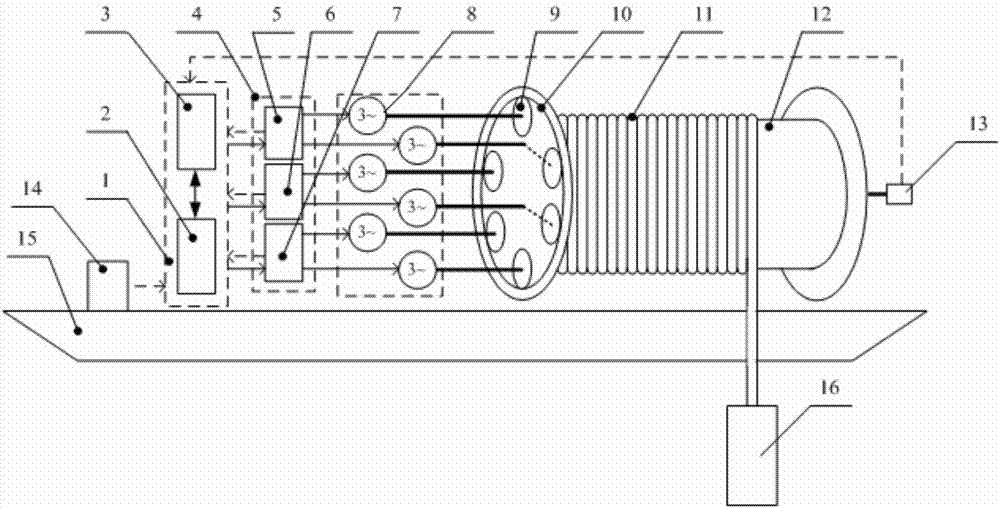

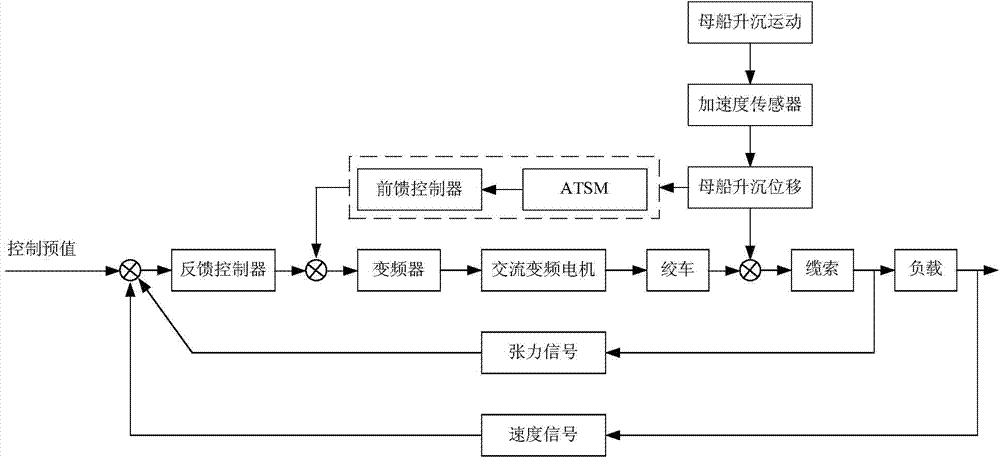

[0022] like figure 1 As shown, the control system of the present invention includes a hot standby redundant controller 1, a frequency converter group 4, an AC variable frequency motor 8, a transmission planetary gear train, an armored umbilical cable 11, a reel 12 and a signal detection sensor, and the signal detection The sensor collects the rotational speed of the reel 12 and the heave acceleration of the mother ship. The signal detection sensor includes an angle encoder 13 and an acceleration sensor 14. The angle encoder 13 is installed on the main shaft of the reel 12, and the acceleration sensor 14 is installed on the mother ship. 13 and the signal output end of the acceleration sensor 14 are connected with the hot standby redundant controller 1, and the collected signal is sent to the hot standby redundant controller 1, and the hot standby redunda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com