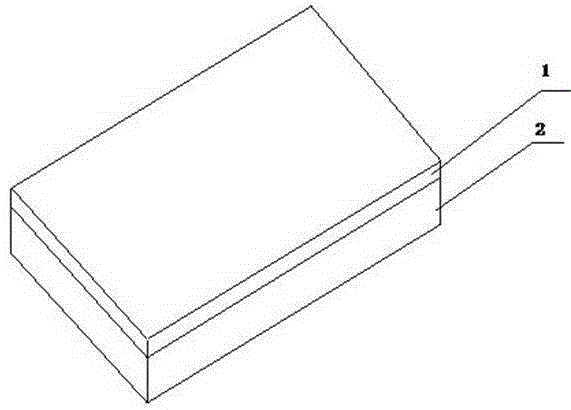

A composite bench surface of plant straw, recycled plastic and recycled rubber

A technology of plant straw and regenerated rubber, applied in the direction of rubber layered products, synthetic resin layered products, lamination, etc., can solve the problems of too hard and uncomfortable sitting feeling, underutilization, poor thermal insulation performance, etc., to achieve thermal insulation Good performance, low density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Corn stalks are selected and processed into straw powder with a particle size of about 160-180um after being dried and crushed.

[0015] Weigh the parts by weight of each raw material of the wood-plastic foam layer according to the formula, put the material in a high-mixer at 80-100°C, store the material at high-speed mixing for 10-20 minutes, put the mixed material into the bench surface mold, and use it as Bottom material: Weigh the parts by weight of the raw materials of the regenerated rubber foam layer according to the formula, plasticize and knead on the open mill for 3-5 minutes, and then produce the regenerated film, cut it and put it into the bench surface mold, and use it as the surface layer material.

[0016] Put the loaded mold in a flat press, press it at 170-190°C and 5-10Mpa for 10-20min, remove the mold and cool it to room temperature, and open the mold to get the finished bench surface.

Embodiment 2

[0018] Wheat straw is selected and processed into straw powder with a particle size of about 160-180um after being dried and crushed.

[0019] Weigh the parts by weight of each raw material of the wood-plastic foam layer according to the formula, put the material in a high-mixer at 80-100°C, store the material at high-speed mixing for 10-20 minutes, put the mixed material into the bench surface mold, and use it as Bottom material: Weigh the parts by weight of the raw materials of the regenerated rubber foam layer according to the formula, plasticize and knead on the open mill for 3-5 minutes, and then produce the regenerated film, cut it and put it into the bench surface mold, and use it as the surface layer material.

[0020] Put the loaded mold in a flat press, press it at 170-190°C and 5-10Mpa for 10-20min, remove the mold and cool it to room temperature, and open the mold to get the finished bench surface.

Embodiment 3

[0022] Wheat straw is selected and processed into straw powder with a particle size of about 160-180um after being dried and crushed.

[0023] Weigh the parts by weight of each raw material of the wood-plastic foam layer according to the formula, put the material in a high-mixer at 80-100°C, store the material at high-speed mixing for 10-20 minutes, put the mixed material into the bench surface mold, and use it as Bottom material: Weigh the parts by weight of the raw materials of the regenerated rubber foam layer according to the formula, plasticize and knead on the open mill for 3-5 minutes, and then produce the regenerated film, cut it and put it into the bench surface mold, and use it as the surface layer material.

[0024] Put the loaded mold in a flat press, press it at 170-190°C and 5-10Mpa for 10-20min, remove the mold and cool it to room temperature, and open the mold to get the finished bench surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com