A bonding resin with high oxygen resistance and water vapor resistance

A bonding resin and oxygen barrier technology, applied in the field of bonding resin, can solve the problems of reduced bonding force and difficult processing technology, and achieve the effect of excellent bonding performance and easy control of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

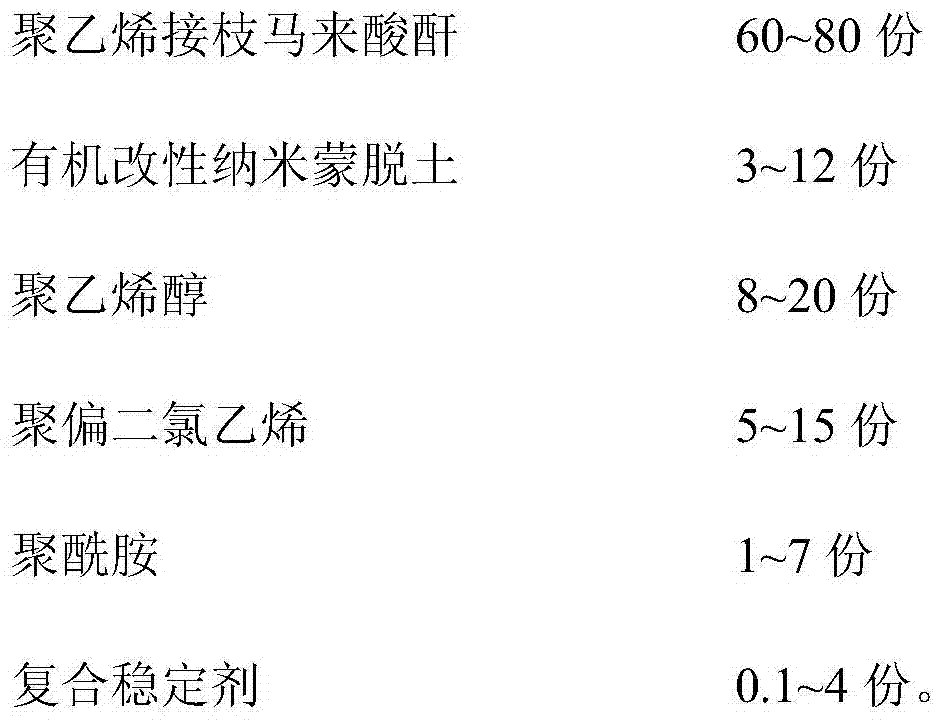

[0026] The weight parts of each raw material component of binding resin described in the present embodiment are as follows:

[0027]

[0028] Specifically, the melt index of the polyethylene-grafted maleic anhydride at 190° C. under 2.16 kg is 1.2-3 g / 10 min.

[0029] Specifically, the organically modified nano-montmorillonite refers to the interlayer treatment of montmorillonite with cetyltrimethylammonium bromide. Water dispersion of montmorillonite; mix and stir cetyltrimethylammonium bromide and concentrated hydrochloric acid in water at 60-80°C to form a uniform protonated solution; then add the uniform protonated solution dropwise to the water of montmorillonite In the dispersion liquid, stir at 60-80°C for at least 1.5h and then filter, wash the filtrate with distilled water, dry it in vacuum to constant weight, and finally pulverize it with a ball mill.

[0030] Specifically, the particle size of the organically modified nano-montmorillonite is 60-80 mesh.

[0031...

Embodiment 2

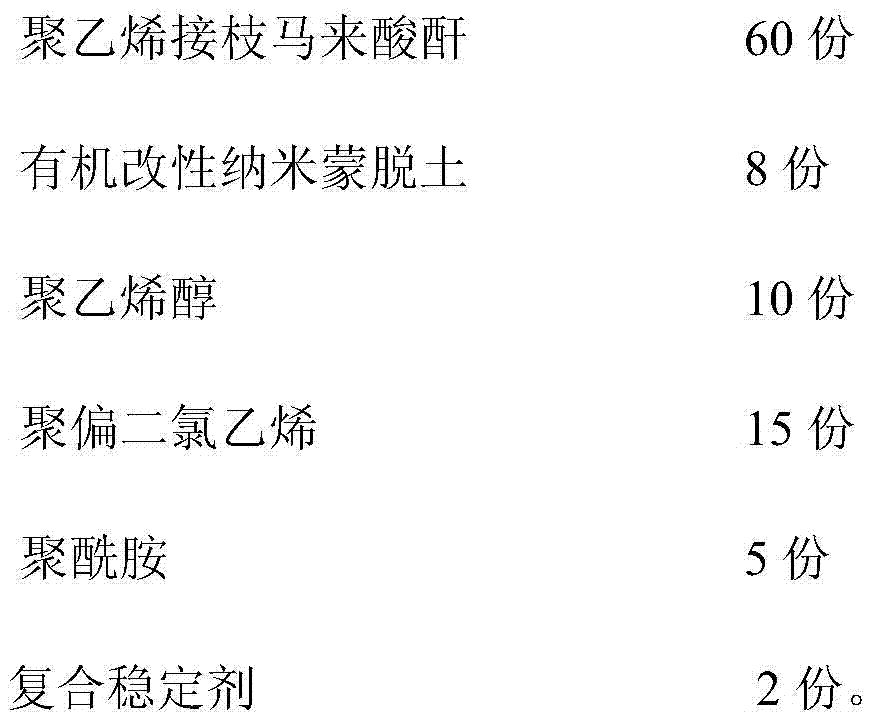

[0040] The weight parts of each raw material component of binding resin described in the present embodiment are as follows:

[0041]

[0042] Specifically, the melt index of the polyethylene-grafted maleic anhydride at 190° C. under 2.16 kg is 1.2-3 g / 10 min.

[0043] Specifically, the organically modified nano-montmorillonite refers to the interlayer treatment of montmorillonite with cetyltrimethylammonium bromide. Water dispersion of montmorillonite; mix and stir cetyltrimethylammonium bromide and concentrated hydrochloric acid in water at 60-80°C to form a uniform protonated solution; then add the uniform protonated solution dropwise to the water of montmorillonite In the dispersion liquid, stir at 60-80°C for at least 1.5h and then filter, wash the filtrate with distilled water, dry it in vacuum to constant weight, and finally pulverize it with a ball mill.

[0044] Specifically, the particle size of the organically modified nano-montmorillonite is 60-80 mesh.

[0045...

Embodiment 3

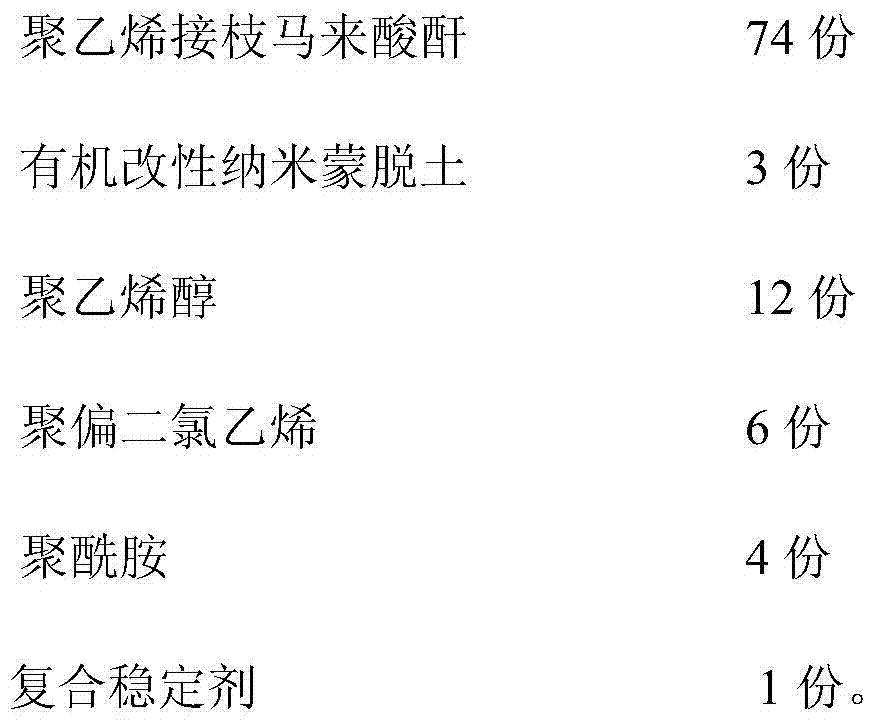

[0054] The weight parts of each raw material component of binding resin described in the present embodiment are as follows:

[0055]

[0056]

[0057] Specifically, the melt index of the polyethylene-grafted maleic anhydride at 190° C. under 2.16 kg is 1.2-3 g / 10 min.

[0058]Specifically, the organically modified nano-montmorillonite refers to the interlayer treatment of montmorillonite with cetyltrimethylammonium bromide. Water dispersion of montmorillonite; mix and stir cetyltrimethylammonium bromide and concentrated hydrochloric acid in water at 60-80°C to form a uniform protonated solution; then add the uniform protonated solution dropwise to the water of montmorillonite In the dispersion liquid, stir at 60-80°C for at least 1.5h and then filter, wash the filtrate with distilled water, dry it in vacuum to constant weight, and finally pulverize it with a ball mill.

[0059] Specifically, the particle size of the organically modified nano-montmorillonite is 60-80 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com