Rolling rock-breaking drill tooth coating material and diamond-tungsten carbide composite drill tooth preparation process

A cemented carbide and preparation technology, which is applied in the field of mining machinery and equipment, can solve the problem that cemented carbide drill teeth are difficult to drill through at one time, so as to improve impact force and crushing energy, increase affinity, and increase wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The coating material of the rolling rock-breaking drill tooth is composed of diamond and bonded matrix material, the particle size of the diamond is 40 mesh, and the quality of the diamond is 25% of the mass of the bonded matrix material; The matrix material is made up of the following components by weight: Co powder is 12 kg, Mn powder is 8 kg, Ni powder is 8 kg, CuSn10 powder is 25 kg, P powder is 2 kg and WC powder is 45 kg; Powder, Mn powder, Ni powder, CuSn10 and P powder have a particle size of 300 mesh, and WC powder has a particle size of 400 mesh.

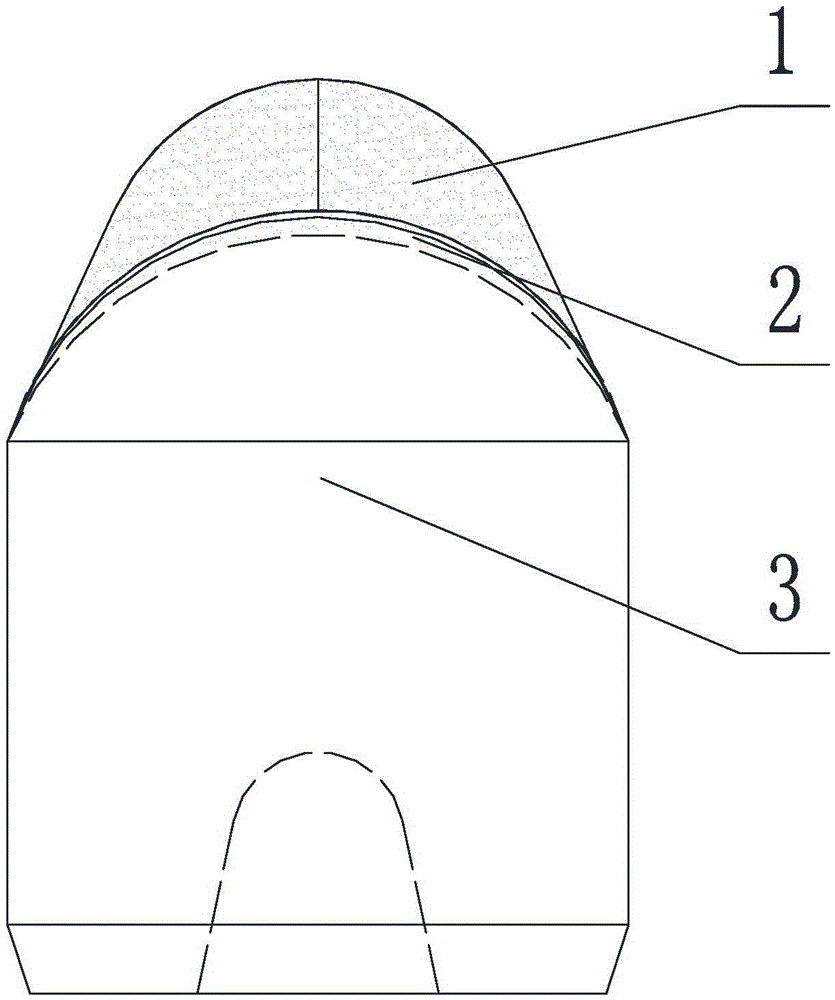

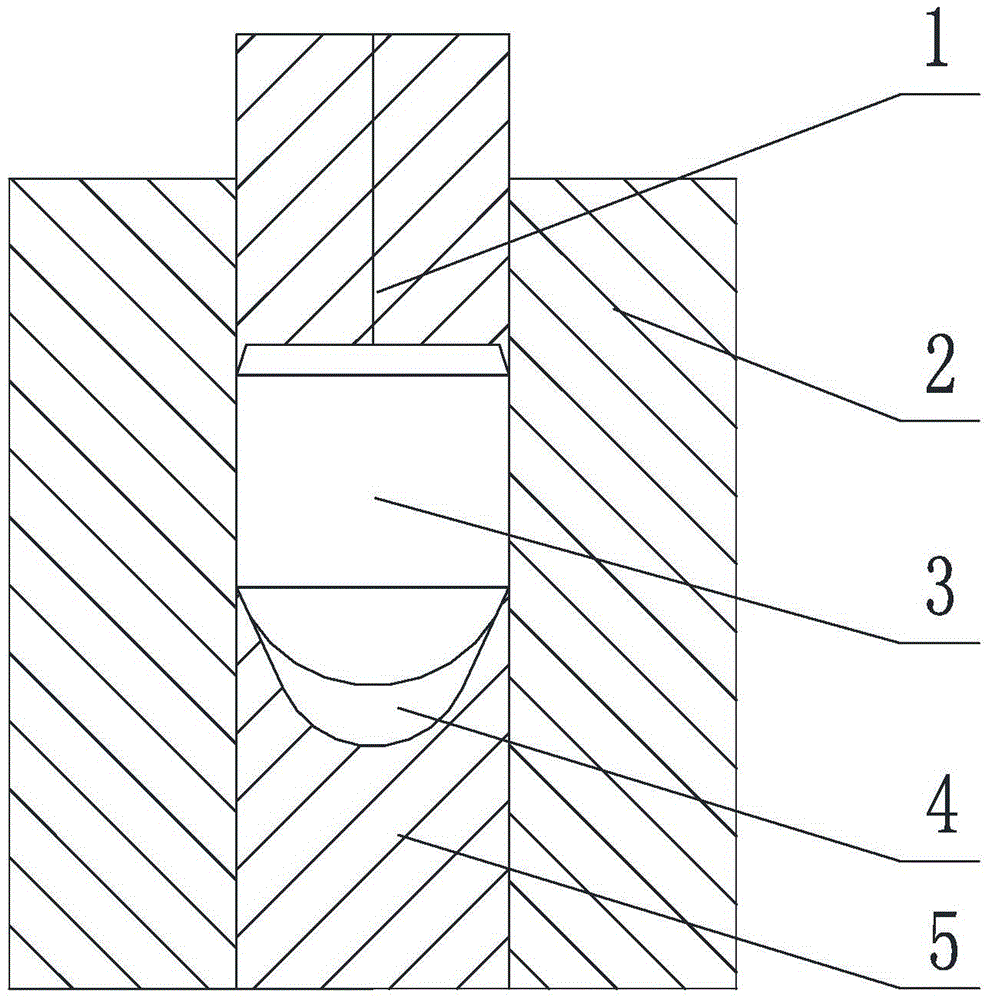

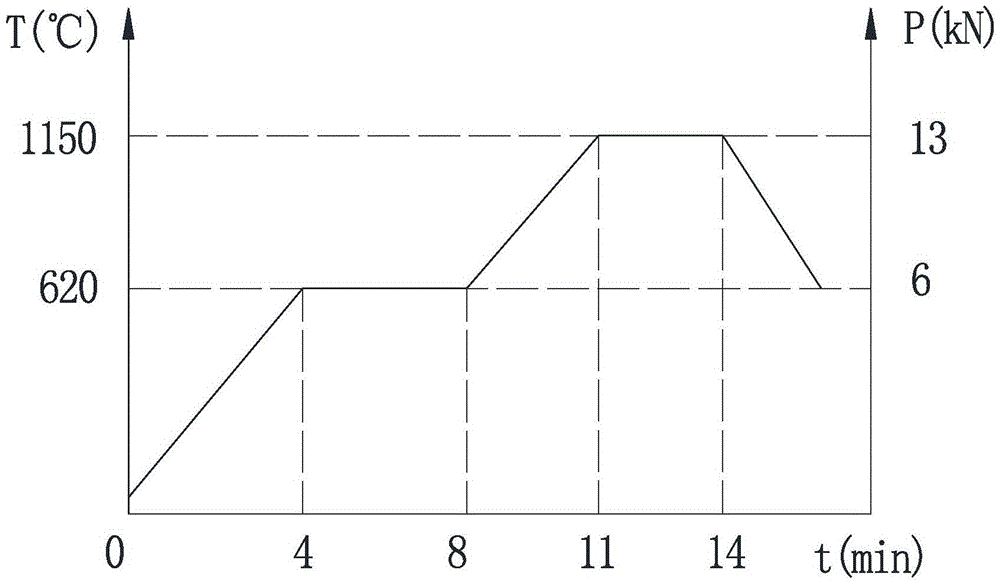

[0026]The preparation process of diamond-tungsten carbide cemented carbide composite drill teeth includes the following steps: (a) Prepare materials: spherical drill teeth and the coating material of the rolling rock-breaking drill teeth, and use the cylinder surface under the ball head of the spherical drill teeth to The outer circle is polished. (b) Vacuum evaporation of titanium on diamond: Put diamond particles...

Embodiment 2

[0028] The coating material of the rolling rock-breaking drill tooth is composed of diamond and bonded matrix material, the particle size of the diamond is 35 mesh, and the quality of the diamond is 22% of the mass of the bonded matrix material; The matrix material is composed of the following components by weight: 10 kg of Co powder, 7 kg of Mn powder, 10 kg of Ni powder, 25 kg of CuSn10 powder, 2 kg of P powder and 42 kg of WC powder. The particle size of Co powder, Mn powder, Ni powder, CuSn10 and P powder is 230 mesh, and the particle size of WC powder is 460 mesh.

[0029] The preparation process of diamond-tungsten carbide cemented carbide composite drill teeth includes the following steps: (a) Prepare materials: spherical drill teeth and the above-mentioned rolling rock-breaking drill tooth coating material, the cylinder surface under the ball head of the spherical drill teeth Use the outer round to polish. (b) Vacuum evaporation of titanium on diamond: place diamond p...

Embodiment 3

[0031] The coating material of the rolling rock-breaking drill tooth is composed of diamond and bonded matrix material, the particle size of the diamond is 50 mesh, and the quality of the diamond is 23% of the mass of the bonded matrix material; The carcass material is composed of the following components by weight: Co powder is 15 parts by weight, Mn powder is 10 parts by weight, Ni powder is 7 parts by weight, CuSn10 powder is 20 parts by weight, P powder is 4 parts by weight and WC powder It is 42 parts by weight. The particle size of Co powder, Mn powder, Ni powder, CuSn10 and P powder is 325 mesh, and the particle size of WC powder is 325 mesh.

[0032] The preparation process of diamond-tungsten carbide cemented carbide composite drill teeth includes the following steps: (a) Prepare materials: spherical drill teeth and the above-mentioned rolling rock-breaking drill tooth coating material, the cylinder surface under the ball head of the spherical drill teeth Use the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com