Air energy generating set

A generator set, gas energy technology, applied in the direction of machine/engine, liquid fuel engine, rotary piston engine, etc., can solve the problem of compressed gas not being completely discharged in time, energy consumption, energy consumption and temperature rise, etc., to alleviate the problem. Smog city problem, solve energy crisis problem, no effect of emissions and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

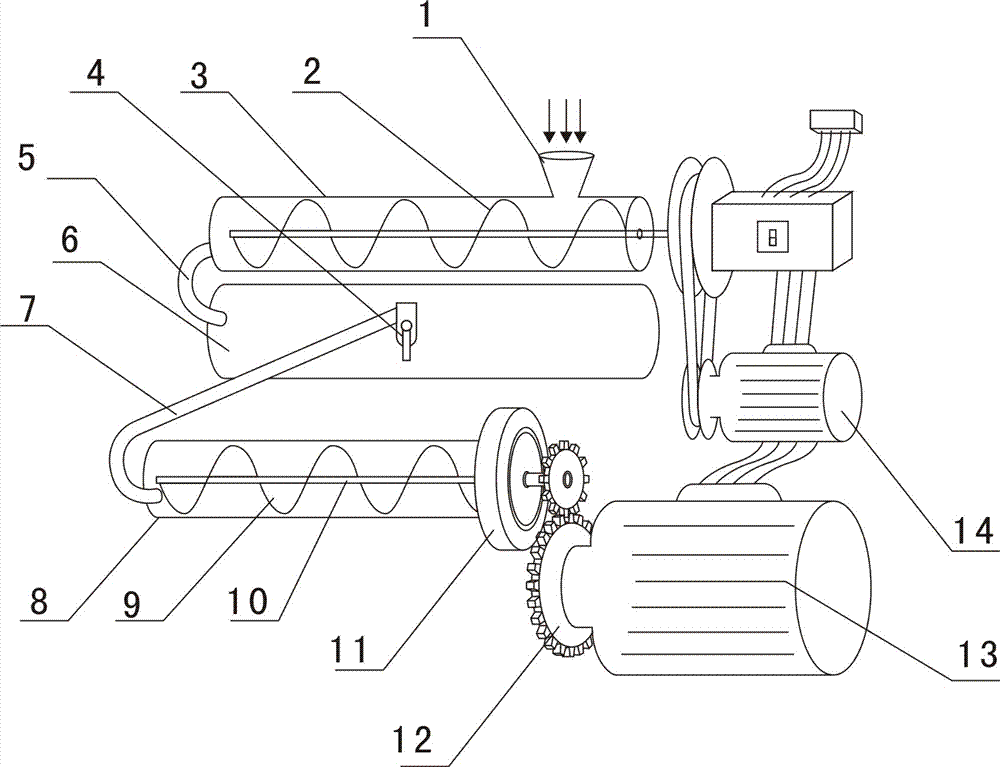

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] The air energy generator set includes a motor 14, the transmission shaft of the motor is connected with the driving shaft of the belt pulley, and the driven wheel shaft is connected with the screw shaft of the air compression pipe 3. The drive shaft is used to drive the driving wheel shaft to rotate, thereby driving the driven wheel shaft and the screw shaft to rotate. Through the belt drive, the impact can be eased and the vibration can be absorbed, so the screw shaft runs smoothly and the noise is small. The screw blade 2 is welded on the screw shaft. The helical blades are distributed on the helical shaft in the form of a cylindrical helix, and the top view of the helical blades is circular.

[0016] An air funnel 1 is provided above the side of the air compression tube close to the pulley. The air funnel is a conical structure and is arranged on the side close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com