Two-dimensional supersonic air inlet passage with variable structure

A technology of air inlet and variable structure, which is applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems affecting engine performance, difficult processing, complex mechanical structure, etc., to improve work efficiency and aerodynamic performance, reduce The effect of small aerodynamic resistance and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a variable-structure two-dimensional supersonic inlet.

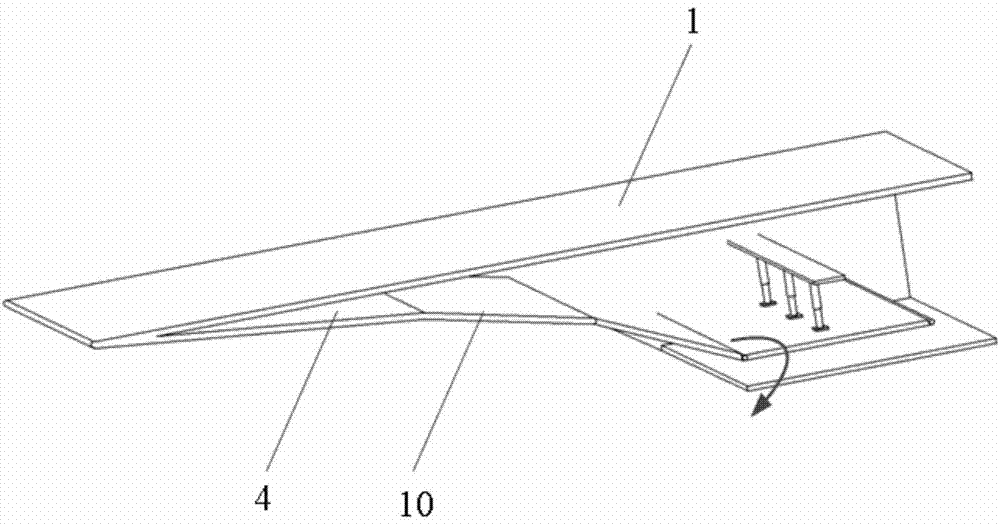

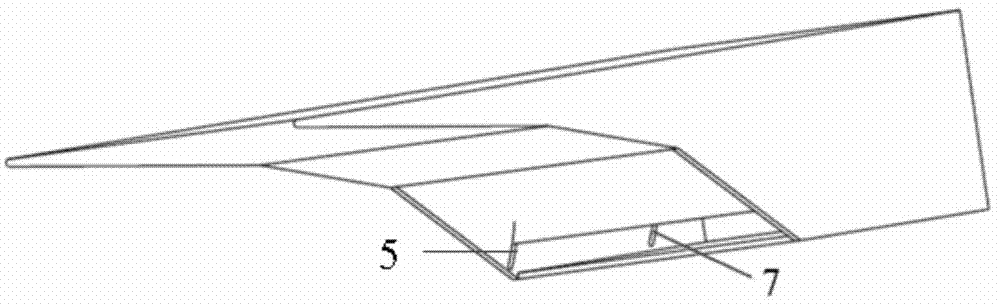

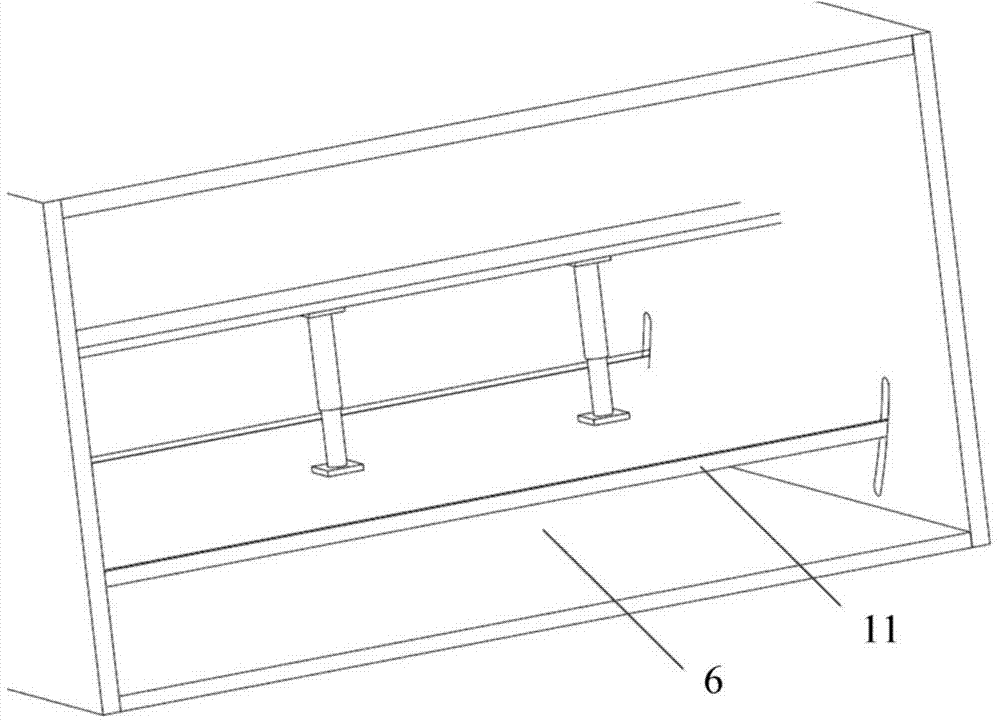

[0020] refer to Figure 1 to Figure 5 , the variable structure two-dimensional supersonic air inlet consists of an air inlet 1, a fixed plate 2, a front compression plate 4, an upper support plate 3, a lower support plate 6, a front sliding groove 5, a rear sliding groove 7, and a first rotating rod 8 , the second rotating rod 9, the movable compression plate 10, the third rotating rod 11, the piston rod 12, the piston cylinder 14, the upper fixed support 13, and the lower fixed support 15; the air inlet 1 is integrated with the aircraft fuselage Structure, symmetrical front sliding groove 5 and rear sliding groove 7 are respectively arranged on the inner side walls of the air inlet 1, the fixed plate 2 is located in the air inlet, the two ends of the fixed plate 2 are fixedly connected with the inner wall of the air inlet 1, and Install in parallel with the upper support plate 3. The upper fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com