Shifting drive structure assembly of gear shifter

A drive structure, shifter technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problem of high machining difficulty and machining accuracy requirements, high cost of transmission mechanism components, and gear shifting. Accuracy adverse effects and other problems, to ensure the service life, facilitate equipment layout, improve the effect of driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

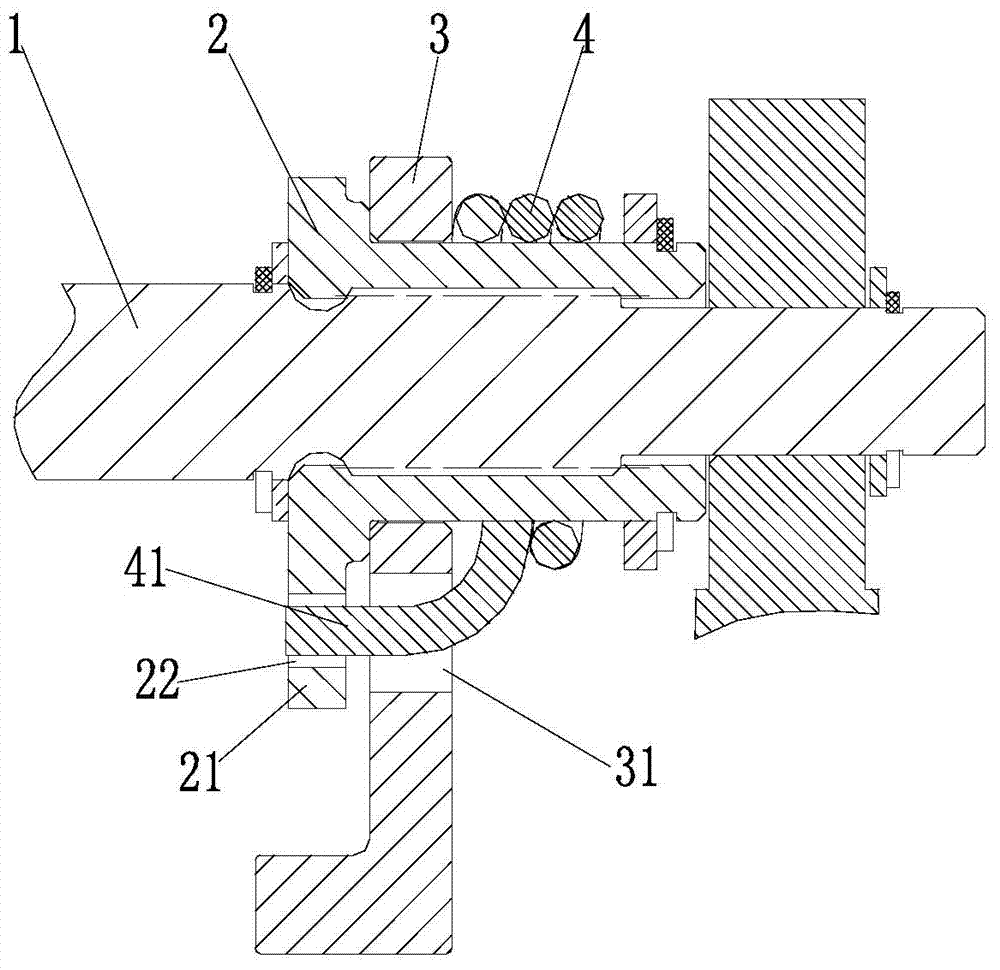

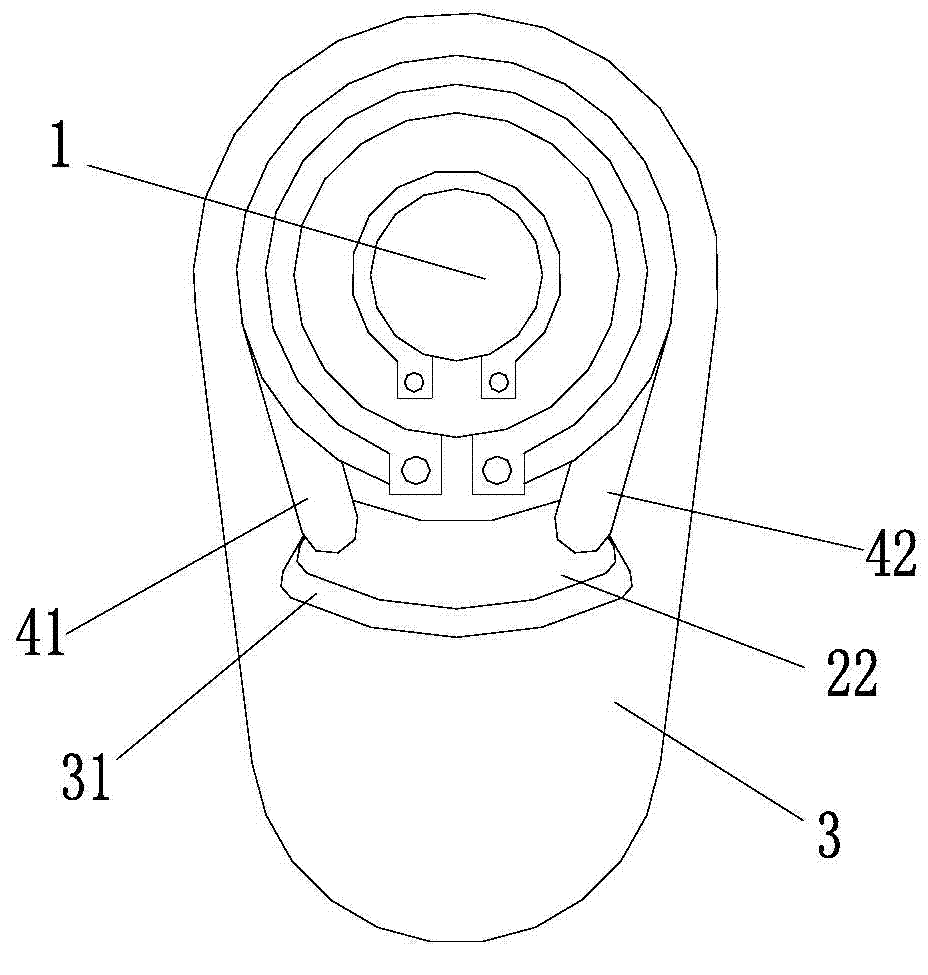

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a side view of the present invention, as shown in the figure: the shift drive structure assembly of the shifter of this embodiment includes a drive member 21 and a shift member 3 for driving a shift fork, and the drive member 21 and the shifter Part 3 is matched in an elastic driving manner; through the elastic drive of the driving part to the shifting part, the shifting fork is driven to shift gears, and the driving structure such as the shifting drum is removed; the connection between the shifting part and the shifting fork can achieve the purpose of shifting As a premise, it will not be repeated here; elastic driving means that the driving force has a certain degree of elasticity during driving, such as driving through a spring or through a shrapnel, which can be realized through a certain mechanical connection.

[0019] In this embodiment, the driving member 21 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com