A control method for automatic speed regulation of range hood based on image analysis

A range hood and automatic speed regulation technology, applied in computer control, program control, and oil fume removal, etc., can solve problems such as poor working conditions, leaving oil stains, and interfering with sensor work, so as to reduce energy consumption, reduce kitchen noise, Guarantee the effect of oil fume exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

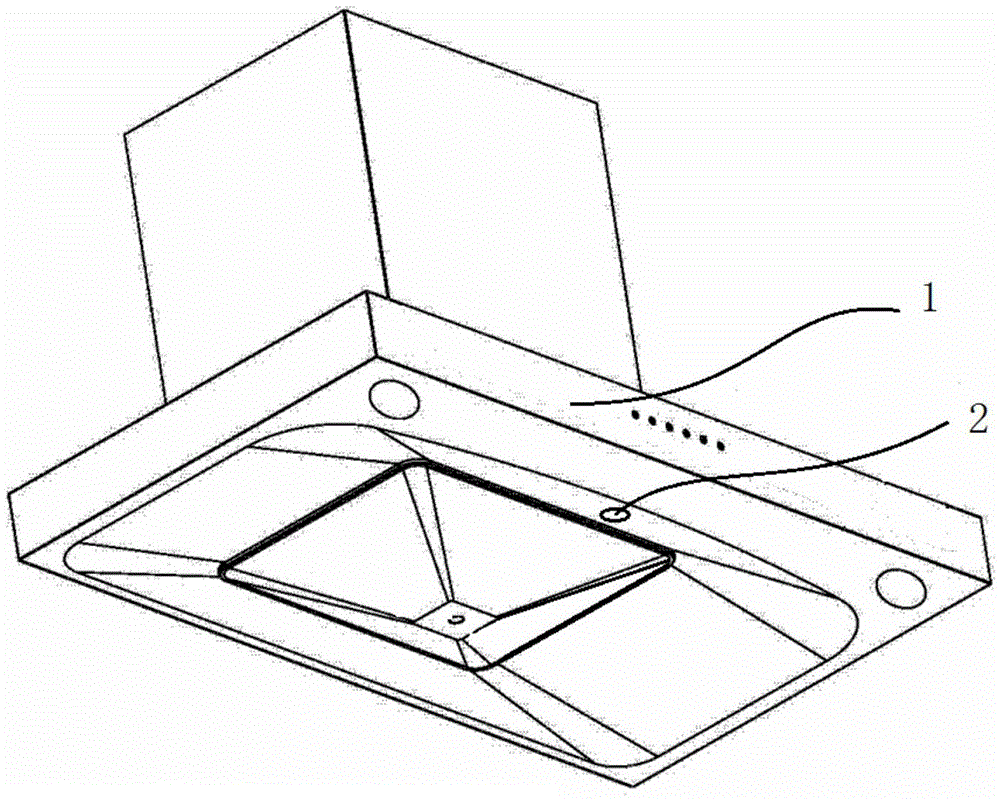

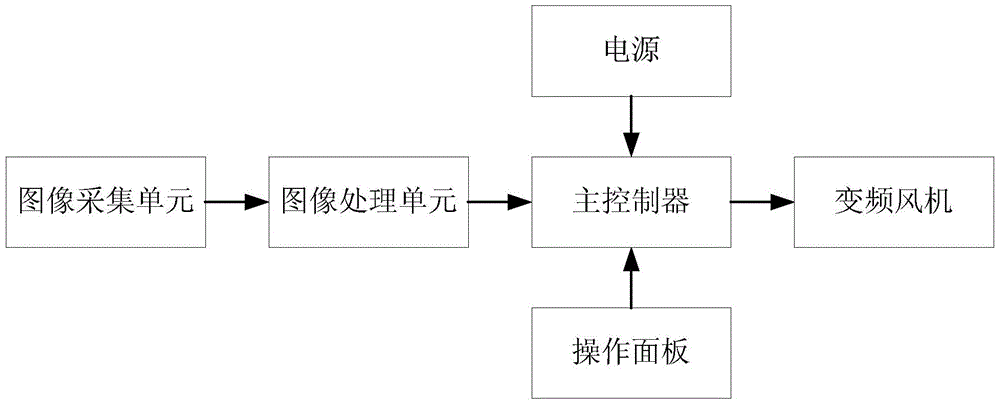

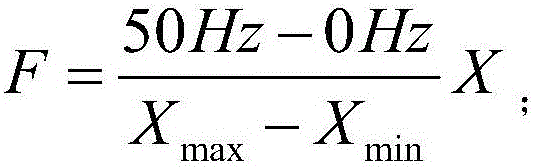

[0021] This specific example figure 1 and 2 As shown, an automatic speed regulation control system for range hoods based on image analysis, specifically includes: an image acquisition unit, used to collect the image of oil fume above the gas stove; an image processing unit, used to collect the image collected by the image acquisition unit The inter-frame difference image of the oil fume image and the oil smoke-free background image is used to extract edge information from the signal source; the main controller is used to quantitatively analyze the edge information as the image feature value to obtain the frequency signal required by the frequency conversion fan; the image processing unit They are electrically connected with the image acquisition unit and the main controller respectively, and the main controller is connected with the frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com