Energy-saving super-absorbent resin polymerizing and drying system

A superabsorbent resin and drying system technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of reducing production costs, polluting the environment, wasting energy, etc., to reduce production costs and protect the environment , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

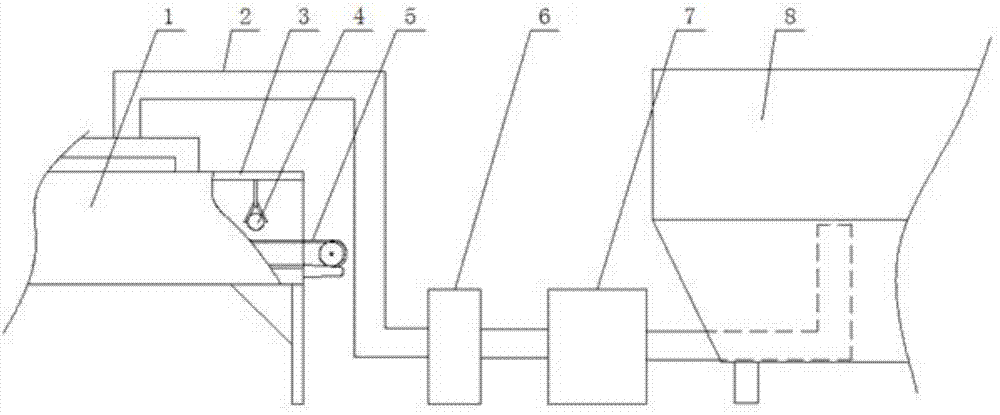

[0017] An energy-saving superabsorbent resin polymerization drying system, including polymerization equipment and fluidized bed drying equipment 8, the innovation is that the polymerization equipment is mainly composed of a mounting frame, a conveyor belt 5, an outer casing 1 and a heating mechanism, A conveyor belt is installed on the mounting frame, an outer casing is installed on the external mounting frame of the conveyor belt, a heating mechanism is installed on the inner shell of the outer casing, and an exhaust duct 2 is connected and installed on the top 3 of the outer casing. , the afterbody of the exhaust duct is connected to the air inlet end of the air compressor 7, and the air outlet end of the air compressor communicates with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap