Device and method for liquid jet spray boundary positioning

A technology of liquid jet and positioning device, applied in measurement devices, optical devices, instruments, etc., can solve problems such as inability to obtain spatial distribution information, and achieve the effect of preventing human intervention, ensuring integrity, and result standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In this embodiment, the boundary positioning is performed on the spray formed by spraying the liquid jet into the air perpendicular to the incoming air flow. The invention can also be implemented in other different ways, such as the boundary positioning of the spray cone when the liquid jet is sprayed into still air.

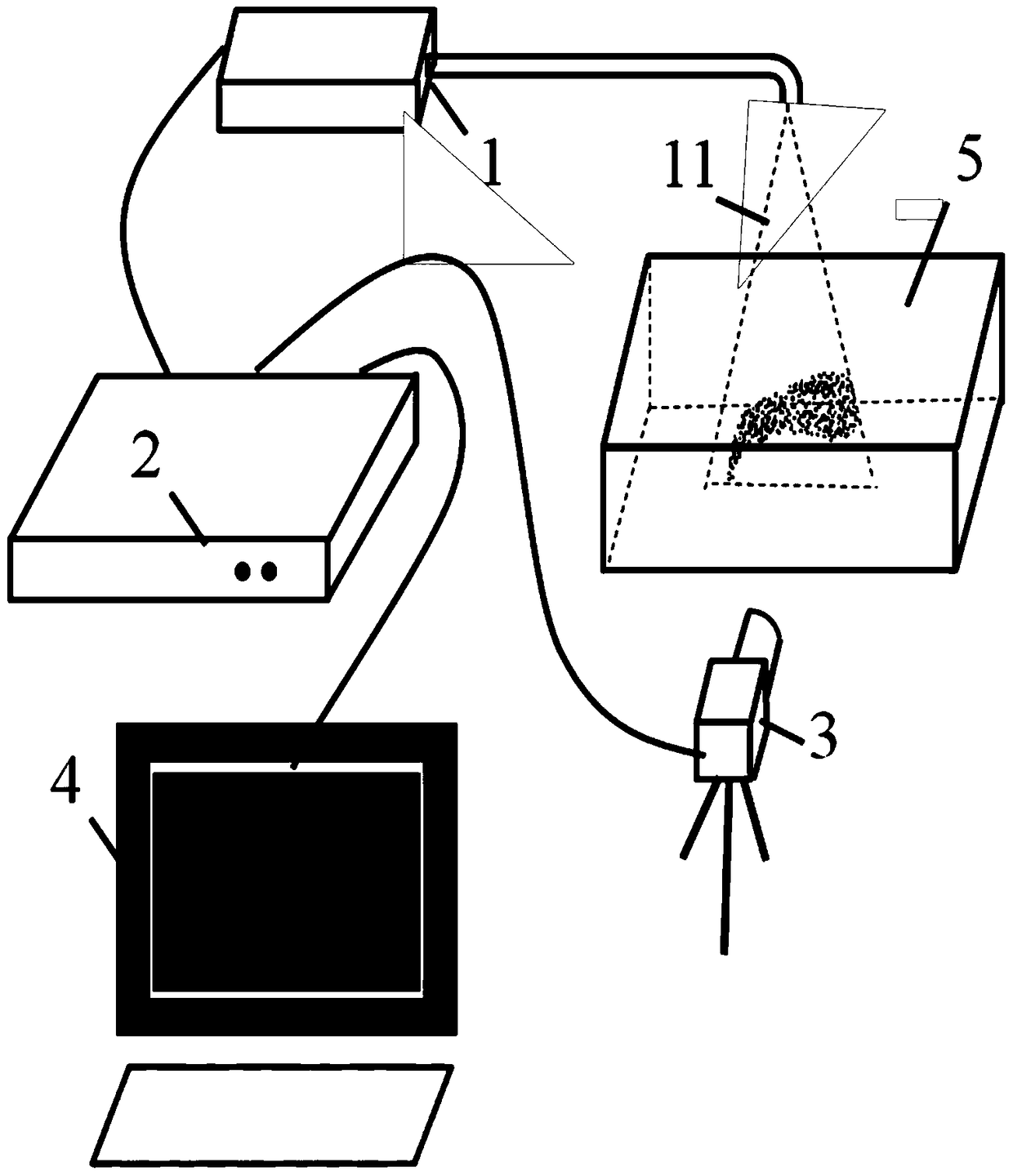

[0027] This embodiment provides a liquid jet spray boundary positioning device, its structure is shown as figure 1 shown. The device includes a sheet laser 1 , a synchronous controller 2 , a CCD camera 3 , a computer 4 and a shooting area 5 .

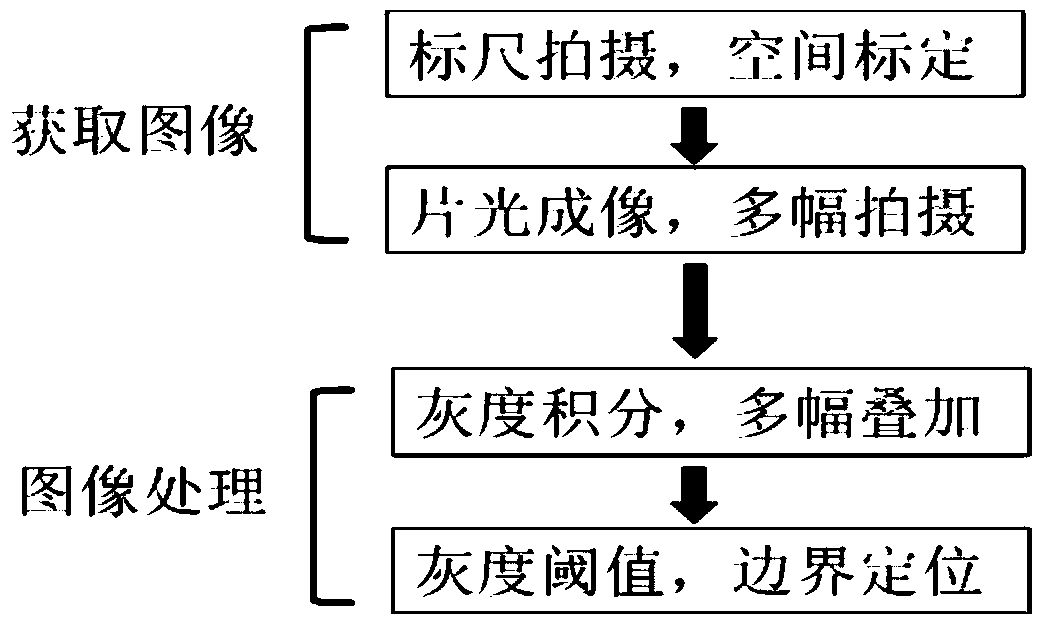

[0028] The boundary positioning process and principle of the present invention are as follows: figure 2 shown. In a dark room environment, the sheet light laser 1 emits pulsed laser sheet light 11 to instantly illuminate a section of the spray, and at the same time, the focal plane of the CCD camera 3 coincides with the illuminated section, and the synchronous controller 2 controls the CCD camera 3 and the shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com