Indirect testing method for non-condensable gas amount of gravity driven two-phase fluid loop

A fluid circuit and gravity-driven technology, applied in the direction of volume measuring instruments/methods, liquid/fluid solid measurement, measuring devices, etc., can solve the problems that cannot be adopted, cannot be accurately analyzed, and cannot determine the volume of non-condensable gas, etc., to achieve Realize the effects of simplicity, improved resolution, and simple and feasible filling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0021] The invention provides an indirect test method for the non-condensable gas volume of a gravity-driven two-phase fluid circuit.

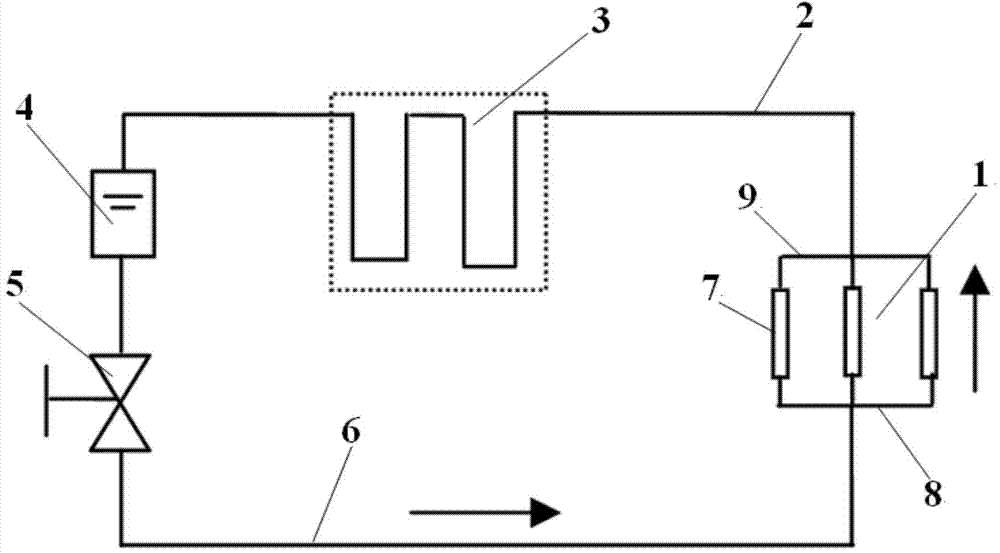

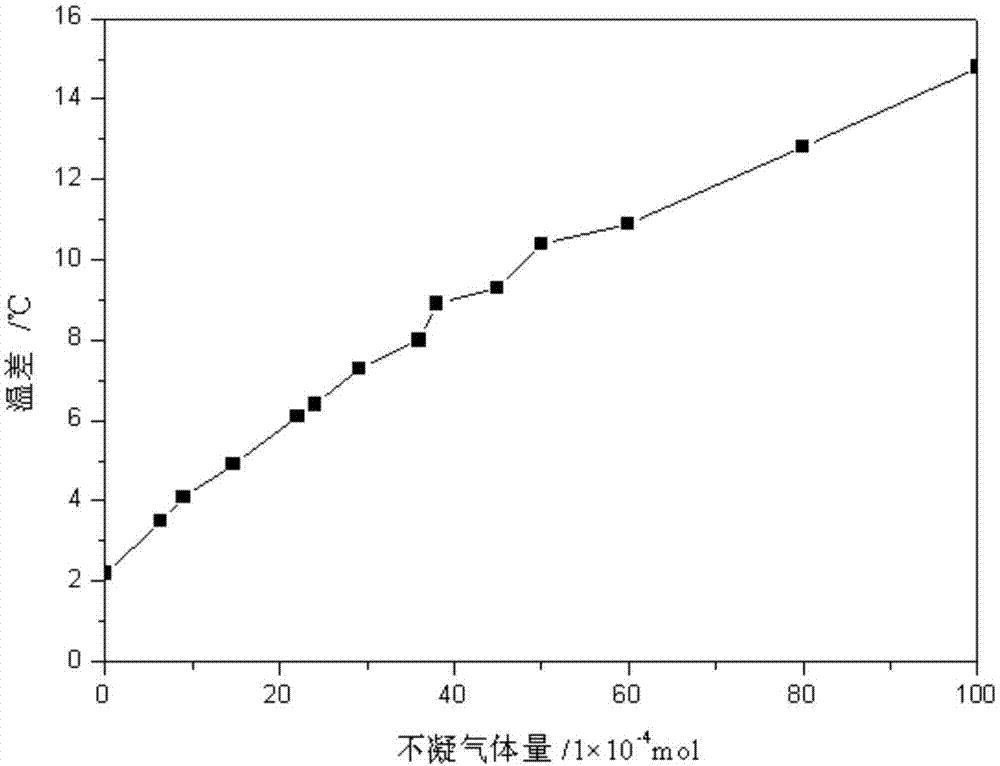

[0022] After the ammonia decomposition of the gravity-driven two-phase fluid circuit produces non-condensable gas, as the gravity-driven two-phase fluid circuit starts to operate during the moonlight period, the non-condensable gas gradually accumulates in the upper gas space of the liquid reservoir 4 with the circulation of the working fluid , forming a component pressure, causing the pressure in the liquid reservoir 4 to increase, thereby increasing the system pressure, and the phase transition temperature of the working fluid in the evaporator 1 increases, that is, the phase transition temperature of the working fluid in the evaporator 1 is higher than that in the liquid storage 4 The two-phase temperature of the medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com