Spiral spring wire pulling liquid level measurement instrument and measurement method thereof

A clockwork spring and liquid level measurement technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of measurement blind spots, susceptibility to interference, complex system, etc., and achieve long measurement distance, wide application range and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

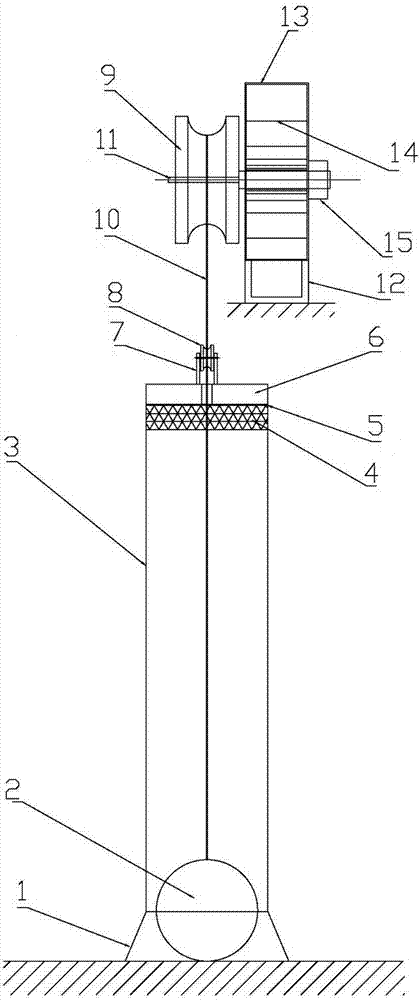

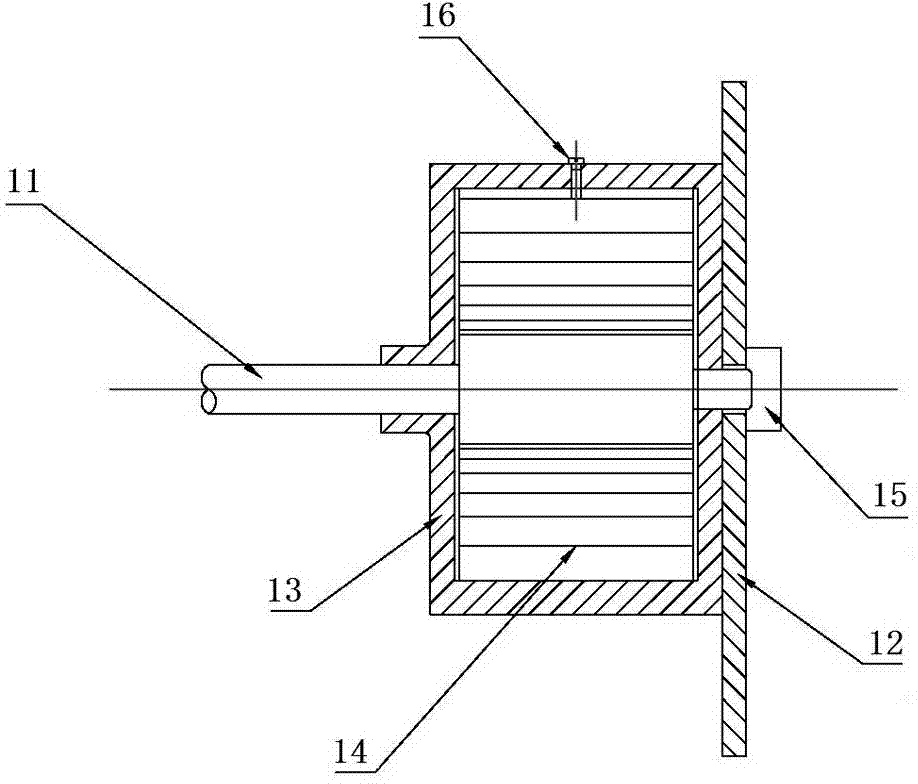

[0029] see figure 1 , figure 2 , the method for measuring the liquid level by the spiral spring wire of the present invention, install a wave reducing tube higher than the highest liquid level in the measured liquid medium, install a float in the wave reducing tube, install a spring box at the observation site, and install a spiral tube in the spring box Clockwork spring, one end of the spiral spring spring shaft is fixed with a wire wheel, the wire wheel and the float are connected by a pull wire, and when the float is at the top of the wave reducing tube, the float is held up at the top of the wave reducing tube when there is no gravity The tension of the spiral spring spring is the initial value; when the liquid level of the measured liquid medium drops, the float will naturally drop due to its own gravity greater than the tension of the spiral spring spring. The shaft of the mainspring spring rotates, and the helical mainspring spring tightens the helical mainspring spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com