Cement grate cooler self-adaptive model prediction controller

An adaptive model and predictive controller technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of complex step response model, inaccurate modeling, difficult model, etc., to achieve good self-control Adaptability, good scalability, guaranteed effect of implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

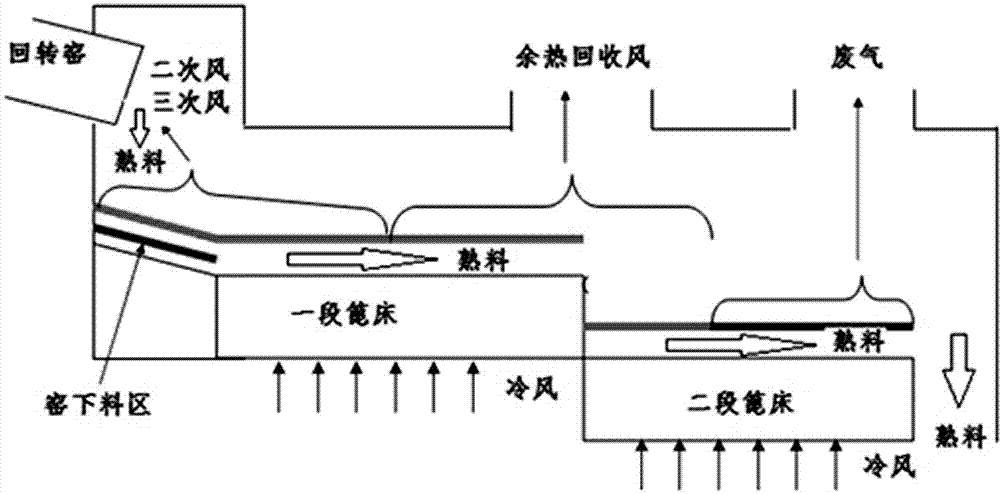

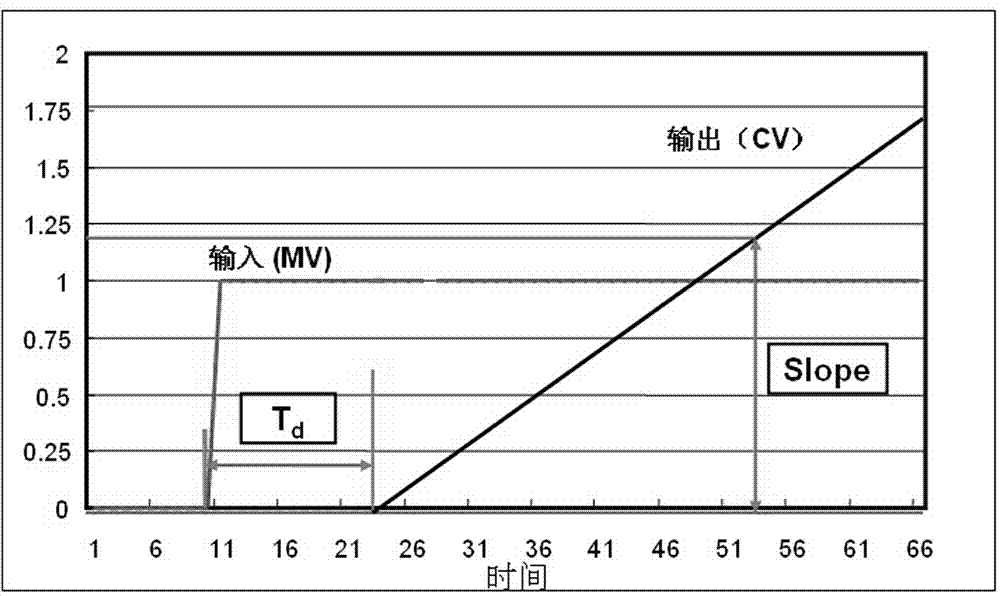

[0038] The self-adaptive model predictive controller of the cement grate cooler of the present invention establishes a model predictive controller to control the thickness of the material layer. The thickness of the material layer is the target of control, which is the controlled variable (CV); the speed of the grate cooler is used to adjust the thickness of the material layer, which is the manipulated variable (MV).

[0039] As another option, the controlled variable can also be replaced by an indirect variable that is closely related to the thickness of the material layer, including the grate down pressure, and / or the transmission hydraulic pressure of the grate cooler, and / or the drive current of the grate cooler, or by the above-mentioned Other variables calculated from the derivatives of the three variables.

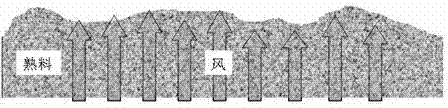

[0040]Due to the complexity of the grate cooler proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com