Turbine blade processing and on-line detection system based on numerical control processing device

A technology for detection systems and turbine blades, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as easy introduction of error points, impact on detection accuracy, expensive system maintenance, etc., to save time and improve system efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

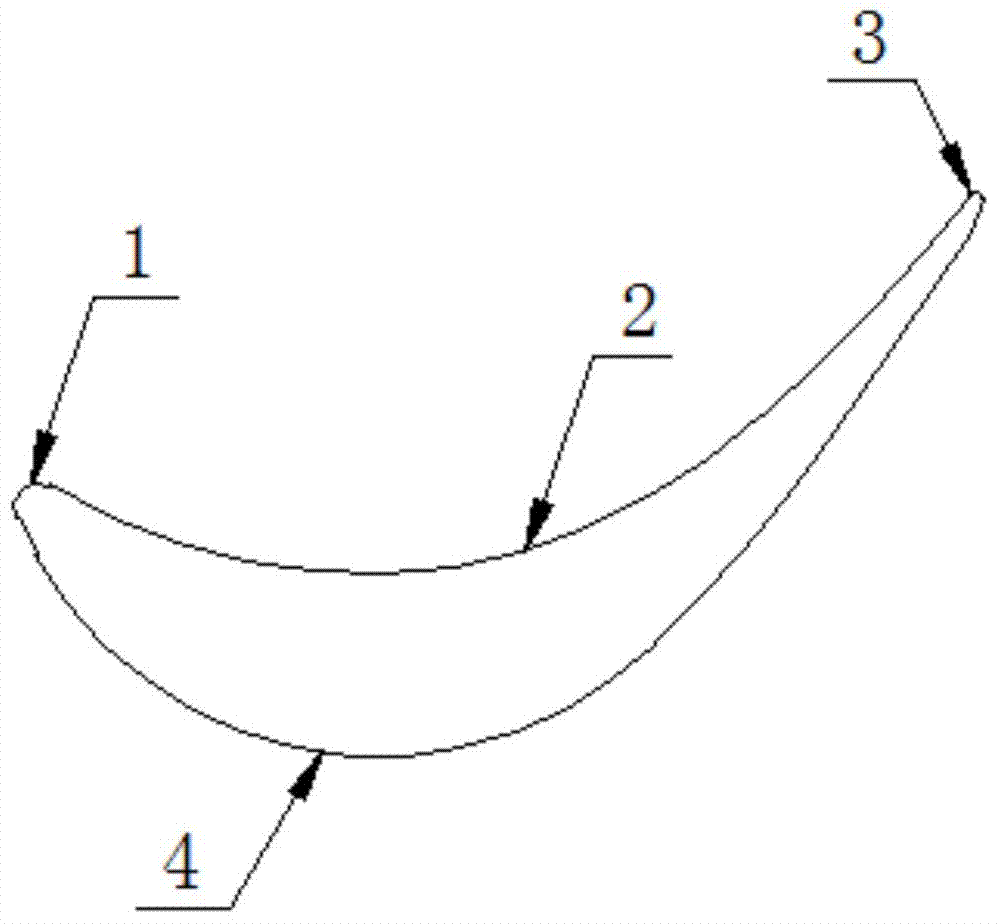

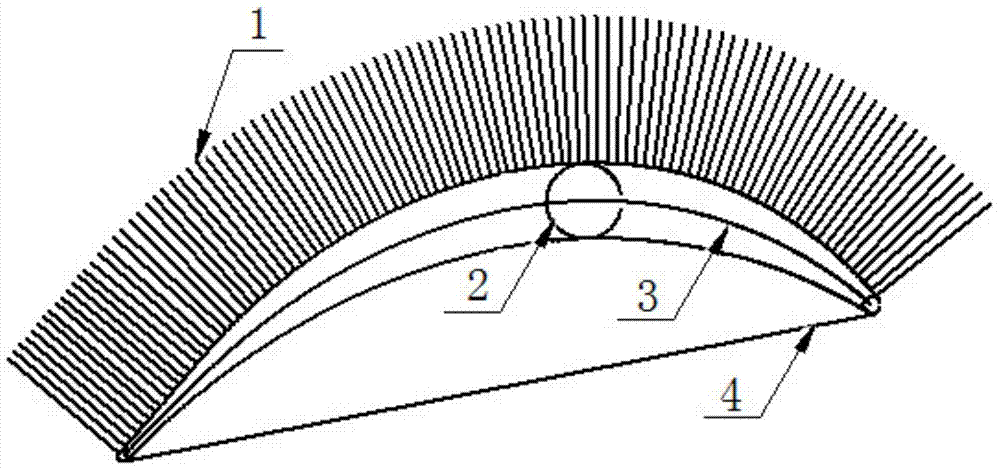

[0026] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

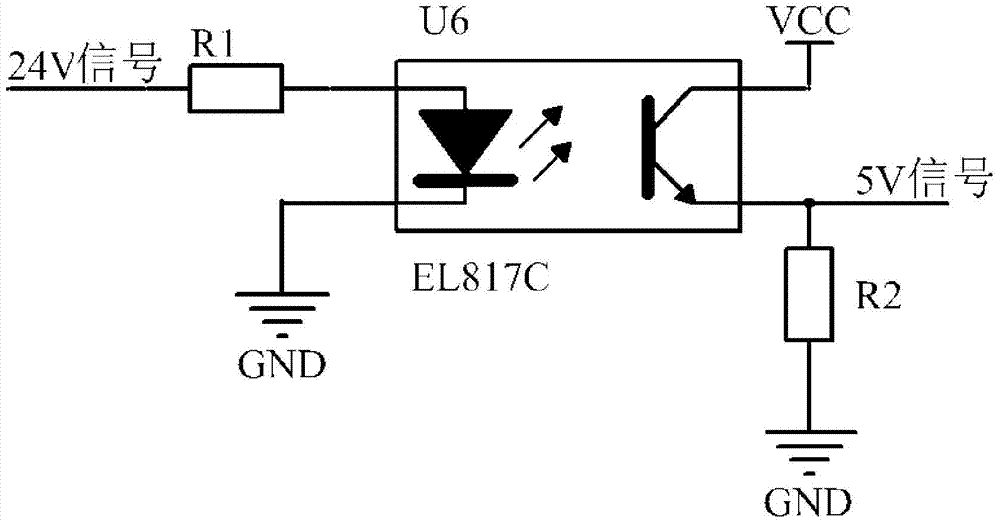

[0027] Since the cooling system of the machine tool is not used in the blade detection process, an external circuit switching module is connected between the operation panel of the CNC machine tool and the cooling system. The numerical control controller is used to correspond to the DO output port of the cooling system, and an external "single-pole double-throw switch" is used to realize the switching between the two states of blade processing and detection.

[0028] Considering other processing purposes of CNC machine tools, if the output interface is not occupied by other outputs in the measurement state, replace the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com