Transfer device for automatic diode combing machine

A technology of transfer device and sliver machine, which is applied in the field of machinery, can solve the problems of increased manufacturing cost of diodes, difficulty in manual handling of diodes, and low work efficiency, and achieves the effects of convenient production and processing, improved production and processing efficiency, and energy saving in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

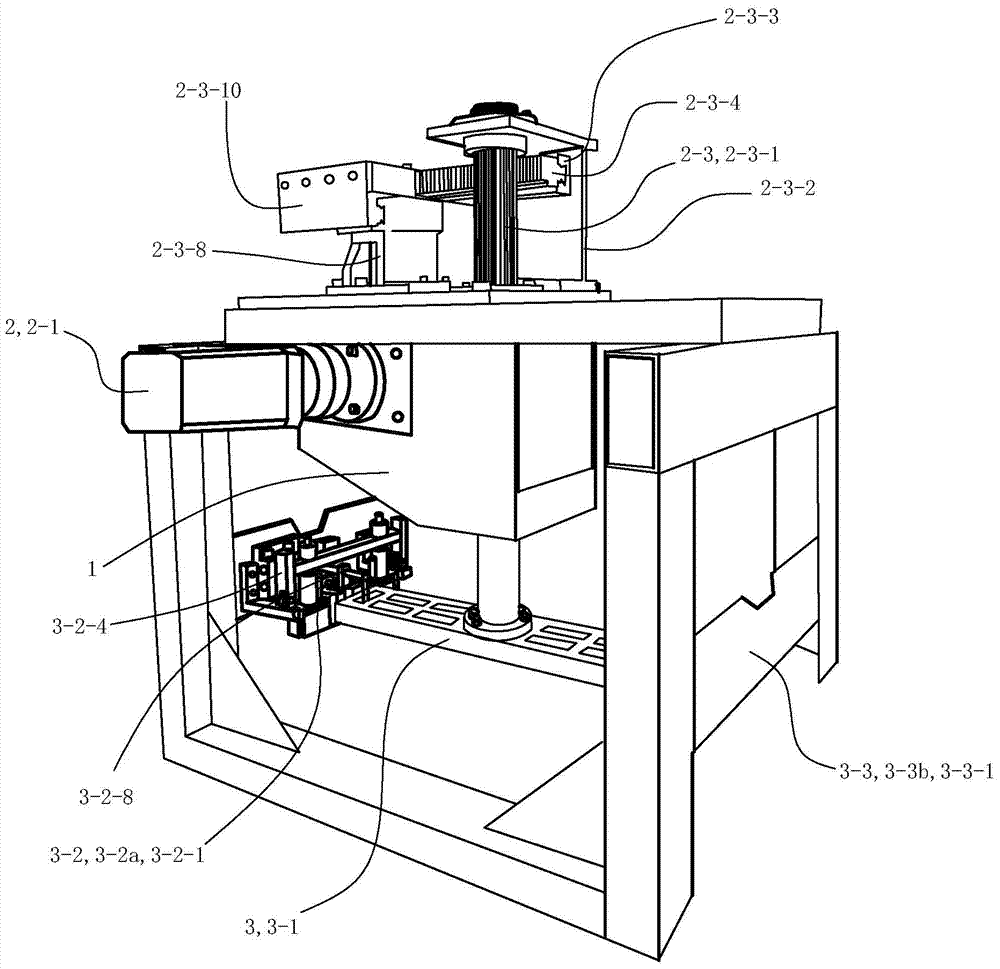

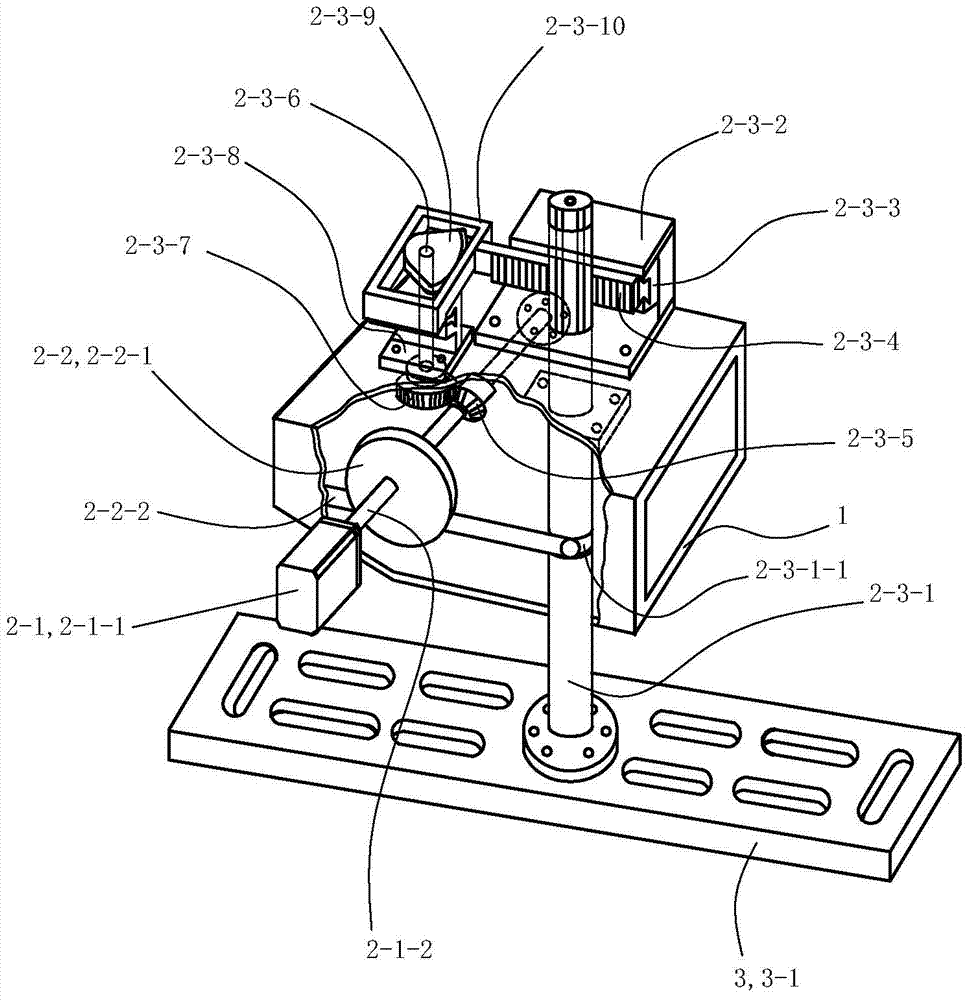

[0053] See figure 2 , The transfer device 2 of the diode automatic sliver machine of the present invention includes a drive mechanism 2-1, a lifting mechanism 2-2 and a rotary mechanism 2-3.

[0054] See figure 1 with figure 2 , the drive mechanism 2-1 includes a motor 2-1-1 and a drive shaft 2-1-2. The motor 2-1-1 is fixedly arranged on the frame 1, and the motor 2-1-1 is arranged horizontally backward by its motor shaft. The drive shaft 2-1-2 is rotatably arranged on the frame, and is connected with the motor shaft transmission of the motor 2-1-1, and the drive shaft 2-1-2 is driven by the motor 2-1-1 to rotate.

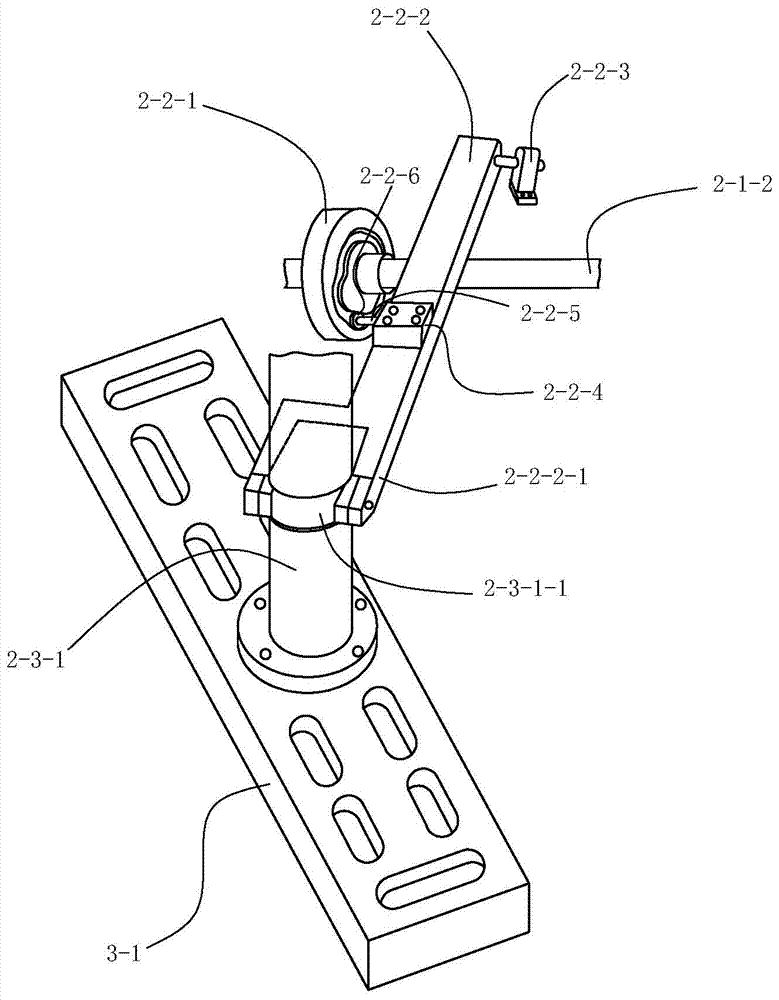

[0055] See figure 2 , image 3 with Figure 7 , the lifting mechanism 2-2 includes a lifting cam 2-2-1, an adjusting arm 2-2-2, an adjusting arm mounting seat 2-2-3, an adjusting arm guide seat 2-2-4, and an adjusting shaft 2-2-5 and guide wheels 2-2-6. The lifting cam 2-2-1 is fixedly arranged on the front part of the drive shaft 2-1-2. The lifting cam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap