Gas purifier

A gas purification device and gas technology, which are used in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficulty in designing the diameter and length of the separation tank, large volume of the separation tank, and decreased separation efficiency, and reduce oil and water. and solid impurities, reducing the amount of impurities, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

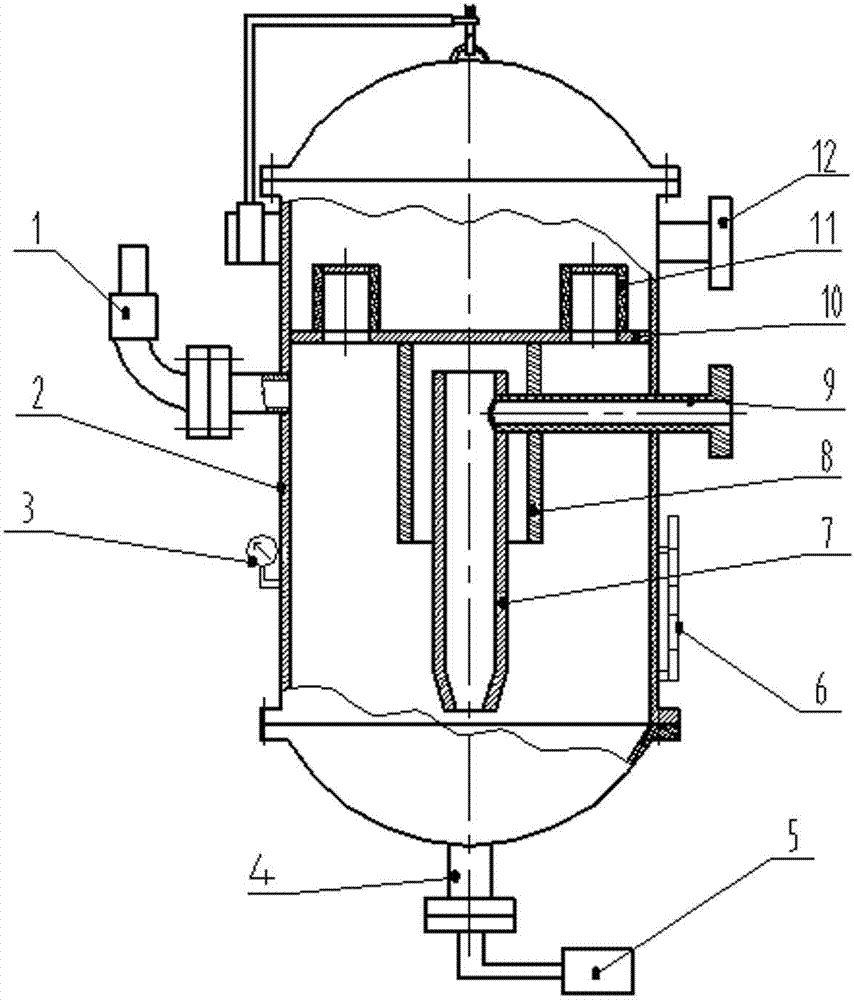

[0016] Refer to attached figure 1 , The gas purification device includes a separation tank, a gas inlet and outlet pipe and a sewage pipe. The separation tank 2 is divided into upper and lower chambers by a partition 10, the upper chamber communicates with the gas outlet pipe 12; the lower chamber is respectively equipped with a safety valve 1, a sewage pipe 4, a liquid level gauge 6 and a pressure measuring device 3 , the sewage pipe 4 is externally connected to the sewage device 5; the partition 10 is processed with a through hole, and a filter 11 is installed on the top, and the lower chamber of the separation tank 2 passes through the through hole on the partition and the filter core of the filter 11. The pores communicate with the upper chamber of the separation tank 2; the lower part of the partition 10 is connected to a round pipe 8, the upper part of the round pipe 8 is sealed and connected with the partition, and the lower part of the round pipe 8 is open; a separatio...

Embodiment 2

[0020] A gas purification device includes a separation tank, a gas inlet and outlet pipe and a sewage discharge pipe. The separation tank is divided into upper and lower chambers by the partition, the upper chamber is connected with the gas outlet pipe; the lower chamber is respectively equipped with a safety valve and a sewage pipe; the partition is processed with through holes, and a filter is installed on the upper part of the separation tank. The lower chamber communicates with the upper chamber of the separation tank through the through holes on the partition and the pores between the filter cores of the filter; the lower part of the partition is connected to a round tube, the upper part of the round tube is sealed with the partition, The lower part is open; a separating circular tube is suspended inside the circular tube; the gas inlet pipe is tangentially inserted into the separating circular tube.

Embodiment 3

[0022] On the basis of Example 2, the upper part of the separating circular tube is cylindrical, and the lower part can be processed into a tapered shape. The cross-section of the gas inlet pipe can be processed into a rectangle or a crescent shape. The round pipe connected to the lower part of the partition can also be processed into a frustum of a cone, that is, an umbrella shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com