Rigid Alloy Plastic Bridge Drain Pipe

A technology of alloy plastics and drain pipes, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of low adhesion strength, heat and weather resistance, dimensional stability, poor impact resistance, seepage, etc., and achieve dimensional stability Strong performance and impact resistance, strong anti-oxidation performance, enhanced adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

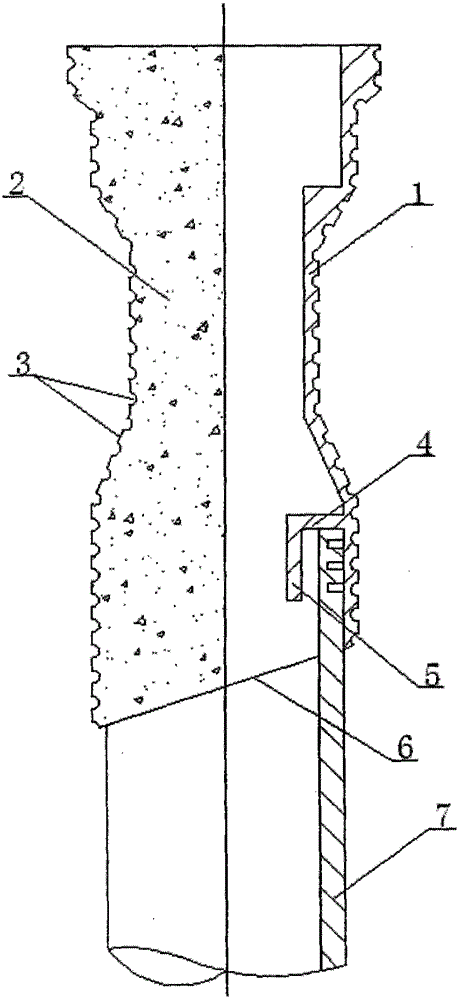

[0020] Such as figure 1 As shown, the rigid alloy plastic bridge drain pipe includes a pre-embedded pipe body 1 and a lower connection pipe 7, the pre-embedded pipe body 1 is straight, the lower end surface of the pre-embedded pipe body 1 is set as an inclined surface 6, and the pre-embedded pipe body The lower end of 1 is connected with the upper end of the lower connecting pipe 7, and the limit platform 4 is arranged on the inner wall of the lower end of the pre-embedded pipe body 1, and the edge of the limit platform 4 is provided with a water-seeking anti-seepage eaves 5, the limit platform 4 and the water-proof anti-seepage The seepage eaves 5 are all ring-shaped, and the upper end of the lower connecting pipe 7 is connected to the inner wall of the embedded pipe body 1 on the outer side of the anti-seepage eaves 5 along the water through a threaded button, and the outer wall of the embedded pipe body 1 is provided with a pitted surface layer 2 , the embossed surface laye...

Embodiment 2

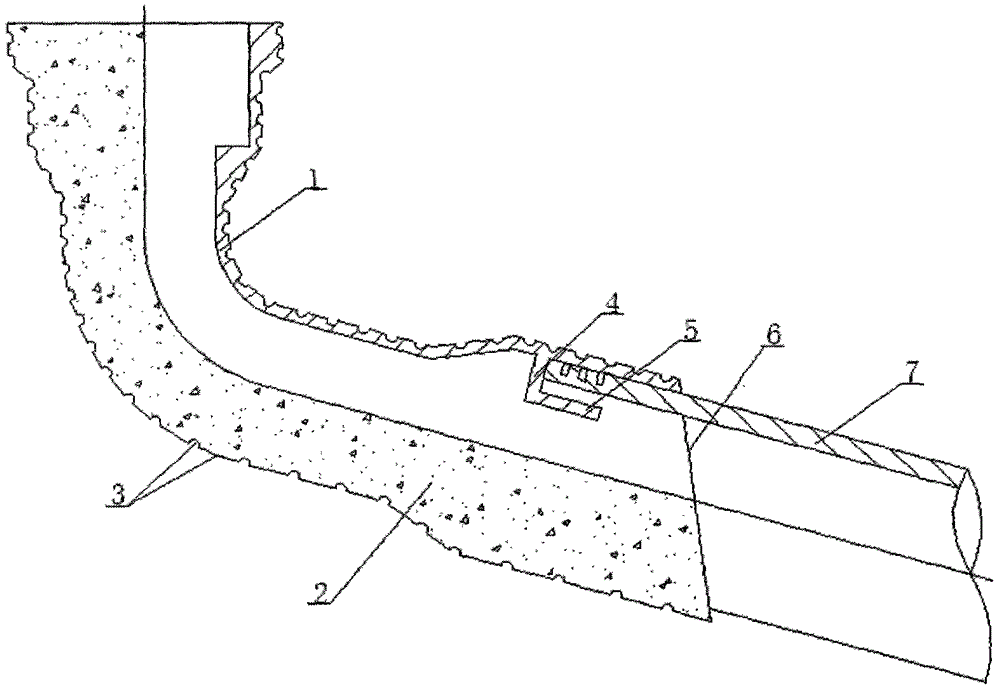

[0022] Such as figure 2 as shown in figure 1 As shown, the rigid alloy plastic bridge drain pipe includes a pre-embedded pipe body 1 and a lower connecting pipe 7. The lower end of the body 1 is connected to the upper end of the lower connecting pipe 7, and the inner wall of the lower end of the pre-embedded pipe body 1 is provided with a limiting platform 4, and the edge of the limiting platform 4 is provided with a water-seeking anti-seepage eaves 5, and the limiting platform 4 and the downstream The anti-seepage eaves 5 are all ring-shaped, and the upper end of the lower connecting pipe 7 is connected to the inner wall of the pre-embedded pipe body 1 on the outside of the anti-seepage eaves 5 along the water through a threaded button, and the outer wall of the pre-embedded pipe body 1 is provided with a pitted surface layer 2. The embossed surface layer 2 is provided with an anti-exfiltration concave-convex groove 3, and the embedded pipe body is made of rigid alloy plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com