Electrodeless lamp amalgam pipe and making technology

A manufacturing process, electrodeless lamp technology, applied in the direction of discharge lamp, discharge tube, electric tube/lamp exhaust, etc., can solve the problem that the heated temperature of the amalgam easily flows into the lamp tube, affects the efficiency and life of the lamp tube, and the amalgam is easy to The problem of flow into the lamp tube, etc., achieves the effect of simple structure, strong practicability, and avoiding waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

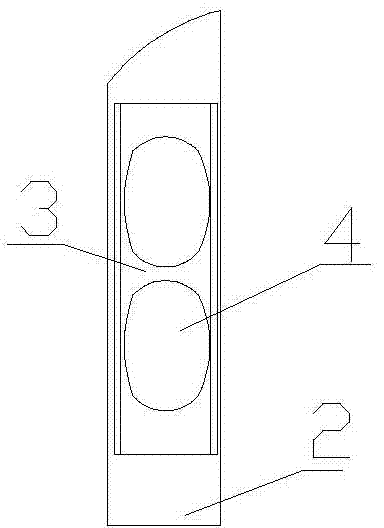

[0028] First, the amalgam tube of the spherical electrodeless lamp and the capillary glass tube inside the amalgam tube are cleaned in dilute hydrofluoric acid solution; one end of the capillary glass tube is sintered and sealed with a flame, and the amalgam is put into the other end of the capillary glass tube and fired Finally, the caliber becomes smaller; the amalgam tube is sealed on the lamp tube, and the amalgam tube is connected with the lamp tube; when the lamp tube is exhausted, the capillary glass tube containing the amalgam is put into the amalgam tube, and the lamp tube And the amalgam tube connected with the lamp tube and the capillary glass tube that is put into the amalgam tube to maintain a vacuum state; the port of the amalgam tube that is exhausted and put into the capillary tube is sealed by flame sintering, so the product is completed; the capillary glass tube The length of the tube is 8 mm, the outer diameter of the capillary glass tube is 2.5 mm, and the i...

Embodiment 2

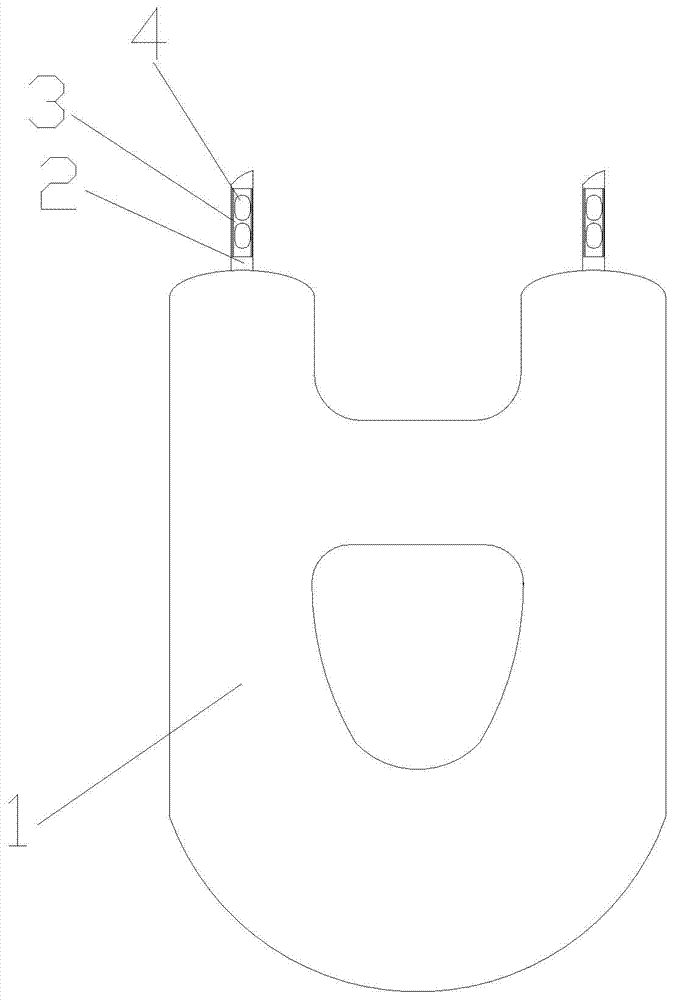

[0030] First, clean the amalgam tube of the U-shaped electrodeless lamp and the capillary glass tube in the amalgam tube in dilute hydrofluoric acid solution; seal one end of the capillary glass tube with flame sintering, put the amalgam from the other end of the capillary glass tube and burn it Make the caliber smaller after making; seal the amalgam tube on the lamp tube, and the amalgam tube is connected with the lamp tube; when the lamp tube is exhausted, put the capillary glass tube with the amalgam The amalgam tube connected to the tube and the lamp tube and the capillary glass tube that is later put into the amalgam tube maintain a vacuum state; the port of the amalgam tube that is exhausted and put into the capillary tube is sealed by flame sintering, so the product is completed; the capillary tube The length of the glass tube is 8 mm, the outer diameter of the capillary glass tube is 2.5 mm, and the inner diameter of the capillary glass tube is 1.5 mm.

Embodiment 3

[0032] First, the amalgam tube of the spherical electrodeless lamp and the capillary glass tube inside the amalgam tube are cleaned in dilute hydrofluoric acid solution; one end of the capillary glass tube is sintered and sealed with a flame, and the amalgam is put into the other end of the capillary glass tube and fired Finally, the caliber becomes smaller; the amalgam tube is sealed on the lamp tube, and the amalgam tube is connected with the lamp tube; when the lamp tube is exhausted, the capillary glass tube with the amalgam in it is put into the amalgam tube, and the lamp tube And the amalgam tube connected to the lamp tube and the capillary glass tube that is put into the amalgam tube to maintain a vacuum state; the port of the amalgam tube that is exhausted and put into the capillary tube is sealed by flame sintering, so the product is completed; the capillary glass tube The length of the tube is 10 mm, the outer diameter of the capillary glass tube is 2.0 mm, and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com