A fully automatic straw pulverizer

A straw pulverizer, fully automatic technology, applied in the direction of harvesters, crop processors, agricultural machinery and implements, etc., to achieve the effect of improved work efficiency, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

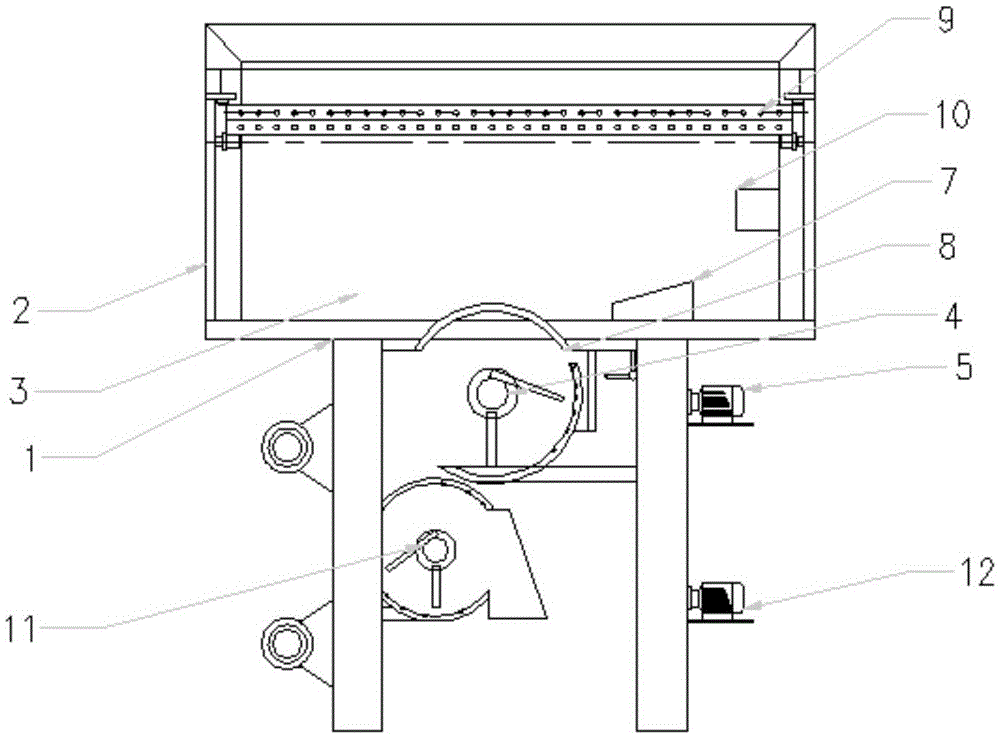

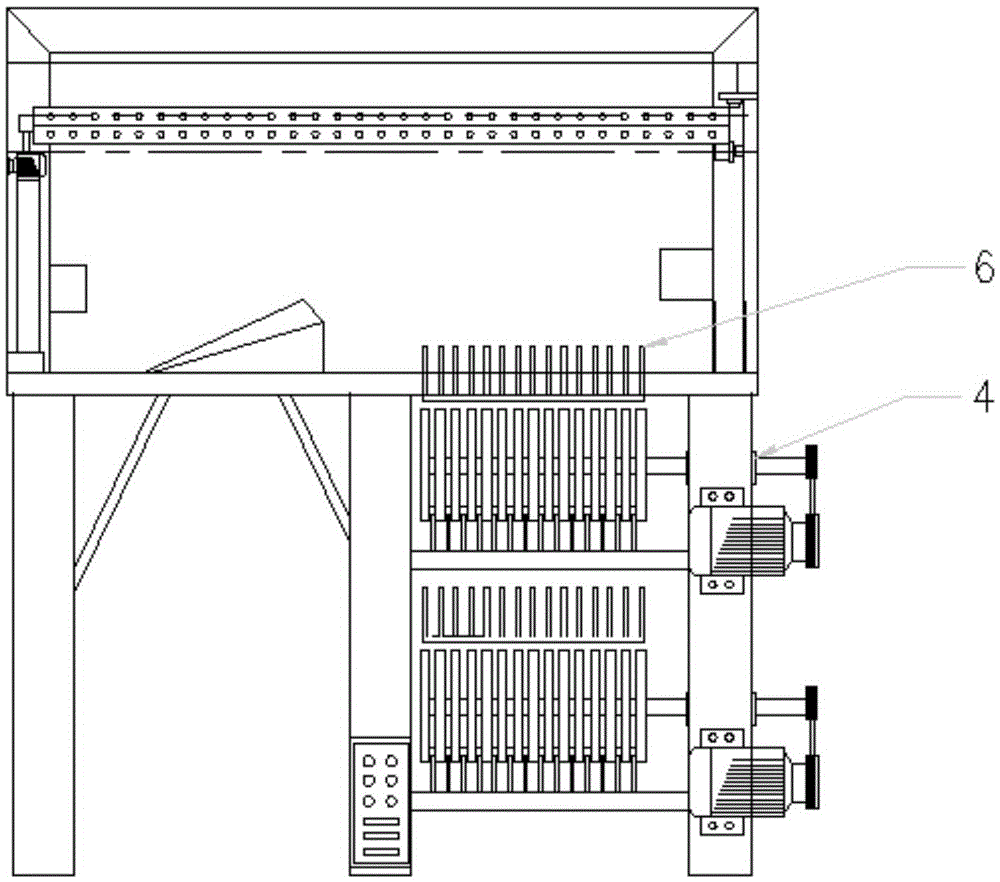

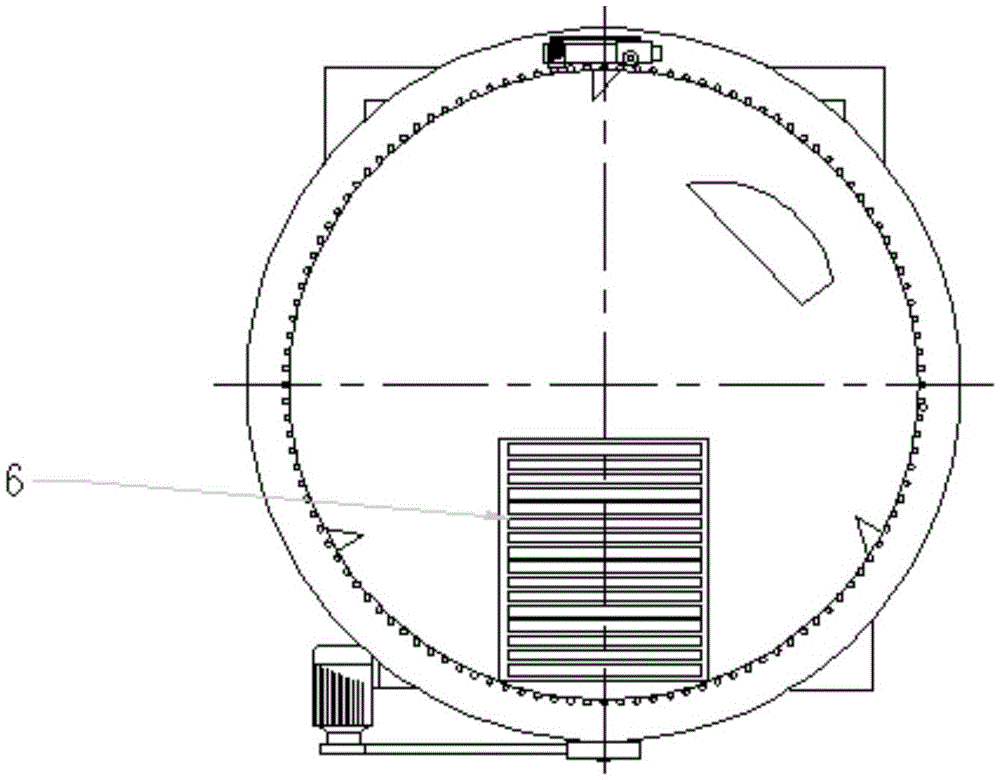

[0018] A fully automatic straw grinder, comprising a frame 1, a rotary feeding bin 2, and a grass cutting device, the frame 1 is provided with a rotating feeding bin 2, and the bottom of the rotating feeding bin 2 is a bin bottom plate 3 , the main shaft 4 of the mowing device is provided with the bottom of the warehouse floor 3, and the main shaft 4 is provided with a blade, a cutter head and a blade pin; the main shaft 4 is driven by a motor-5 through a belt; A grid 6 is installed at the opening of the bin bottom plate 3 that the bottom plate 3 contacts; the bottom of the rotary feeding bin 2 is also provided with an idler wheel, and the rotary feeding bin 2 rotates without a shaft, and is supported and oriented by the idler wheel. The idler wheel is driven by the second motor; the inside wall of the rotary feeding bin 2 is provided with a sloping plate 7 for pushing grass, and the bottom plate of the warehouse is equipped with an oblique circular arc mowing block 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com