Chitosan dressing and production process thereof

A production process, chitosan technology, applied in the field of medical supplies, can solve the problems of complex performance control of chitosan, unfavorable solubility, poor appearance, poor moisture retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

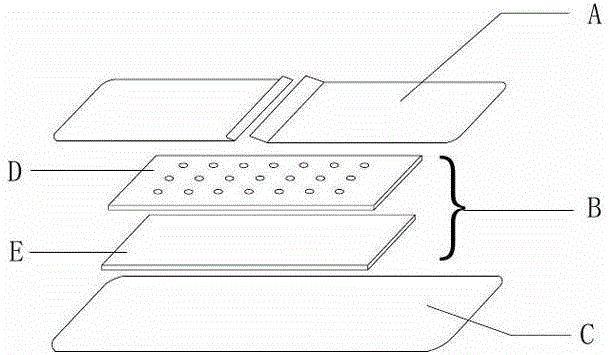

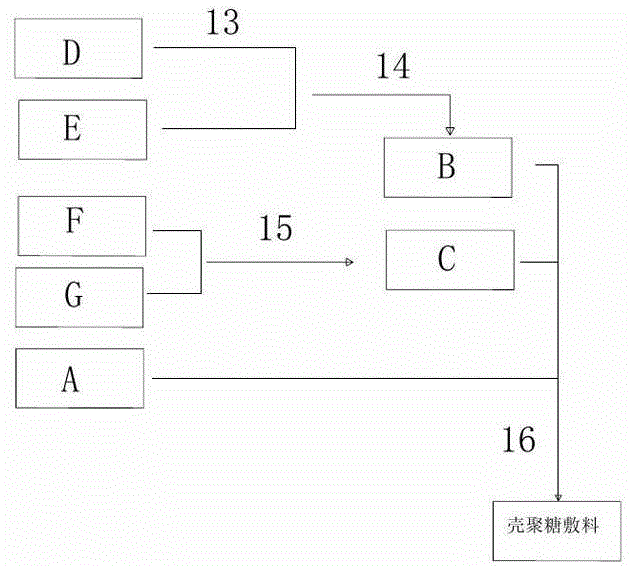

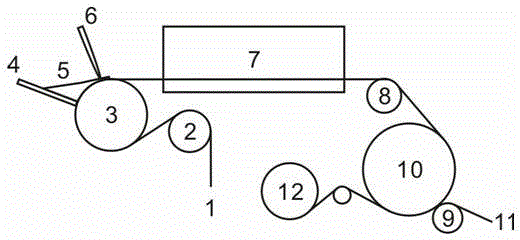

[0037] Example 1: Reference figure 1 , figure 2 and image 3 :

[0038] Take 350g of carboxymethyl chitosan with a molecular weight of 30,000, a deacetylation degree of 90%, a substitution degree of 0.75, a pH of the insoluble region of 4~7.5, and a pH of 7.5~9 of the swelling region, add 1100g of glycerin, and 8550g of purified water, and stir well Swell to get a coating with a viscosity of 7000mpa.s, add figure 1 In the trough of the coating machine with the structure, start the traction roller to drag the anti-sticking paper, adjust the gap between the knife edges to 0.8mm, and measure the coating amount of 648g per square meter, enter the oven, and the coating machine oven has 5 sections, and the temperature of each section is set in order. The next time is 50°C, 60°C, 70°C, 80°C, 70°C, reduce the weight to 85%, cover the pressure roller with non-woven fabric, wind up, and the roll material enters the oven again, the temperature of each section is as above, wind up, A...

Embodiment 2

[0040] Take 350g of carboxymethyl chitosan with a molecular weight of 96,000, a degree of deacetylation of 95%, a degree of substitution of 0.87, a pH of 4~7.5 in the insoluble region, and a pH of 7.5~9 in the -swelling region, add 1100g of glycerin, 8550g of purified water, and stir well Swell to get a coating with a viscosity of 8000mpa.s, add figure 1 In the trough of the coating machine with a structure, start the traction roller to drag the anti-sticking paper, adjust the gap between the knife edges to 0.8mm, and measure the coating amount to 740g per square meter, enter the oven, and the coating machine oven has 5 sections, and the temperature of each section is set in order. The second time is 50°C, 60°C, 70°C, 80°C, 70°C, the weight is reduced to 83%, the pressure roller is covered with non-woven fabric, and the roll is wound. The roll material enters the oven again. The temperature of each section is as above, and the roll is rolled. After two hours, the coil material...

Embodiment 3

[0042] Take 400g of carboxymethyl chitosan with a molecular weight of 16,000, a degree of deacetylation of 83%, a degree of substitution of 0.7, a pH of 4 to 7.5 in the insoluble region, and a pH of 7.5 to 9 in the swelling region, add 1200g of glycerin, and 8400g of purified water, and stir well Swell to get a coating with a viscosity of 6000mpa.s, add figure 1 In the trough of the coating machine with the structure, start the traction roller to drag the anti-sticking paper, adjust the gap between the knife edges to 0.8mm, and measure the coating amount of 720g per square meter, enter the oven, and the oven of the coating machine has 5 sections, and the temperature of each section is set in order The second time is 50°C, 60°C, 70°C, 80°C, 70°C, the weight is reduced to 82%, the pressure roller is covered with non-woven fabric, and the roll is wound. The roll material enters the oven again. The temperature of each section is as above, and the roll is rolled. After two hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com