A photocatalyst bi 4 o 5 br 2 The synthesis and application method of

A photocatalyst and synthesis method technology, applied in the field of nanomaterials, can solve the problems of impure catalyst, low Br content, long time required, etc., and achieve the effects of good photocatalytic activity, stable performance and single composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

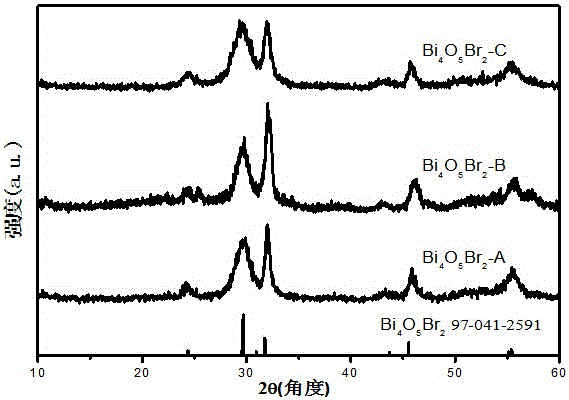

[0019] 4.85g Bi(NO 3 ) 3 ·5H 2 O was added to 40 mL of ethylene glycol and stirred at room temperature for 1.5 h, then 1.19 g of KBr was added under stirring, and continued stirring until a clear solution was formed, then 16 mL of H was added to the solution. 2 O and 4 mL NH 3 ·H 2 A mixed solution of O, adjust the pH of the solution to 9, and react continuously for 4 hours under this condition until a precipitate is formed, and finally separate, wash and dry the obtained precipitate to obtain Bi 4 o 5 Br 2 Catalyst, denoted as Bi 4 o 5 Br 2 -A.

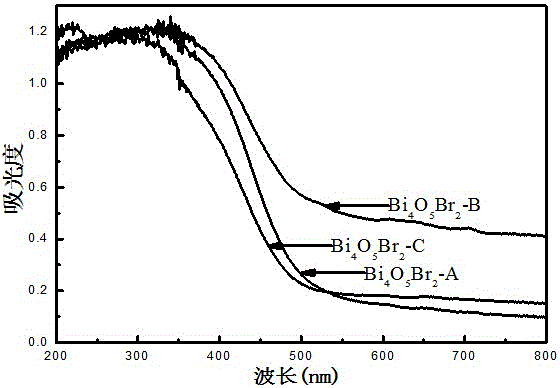

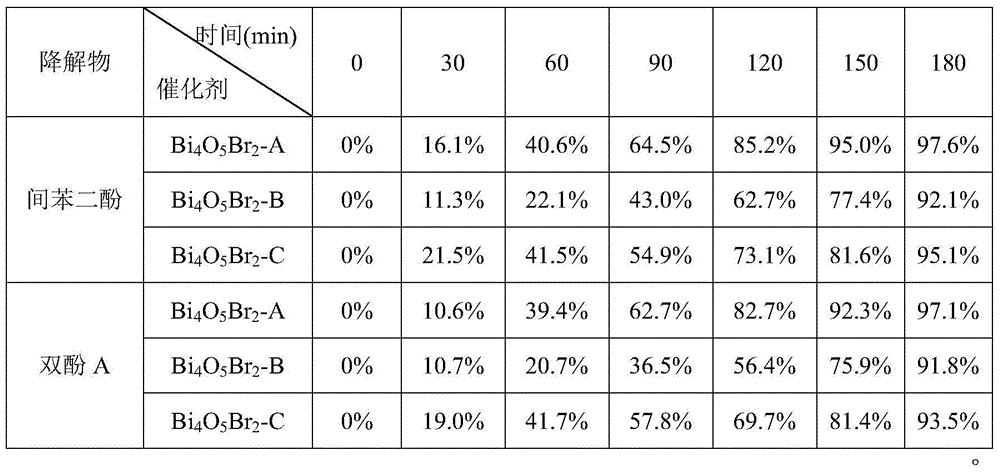

[0020] Income Bi 4 o 5 Br 2 -A photocatalyst is used for photocatalytic degradation of resorcinol and bisphenol A solution. The reaction conditions are: normal temperature and pressure, the amount of catalyst is 0.1g, the treatment amount of organic pollutant resorcinol or bisphenol A in water is 100mL, 10mg·L -1 , the light source used is a xenon lamp, the power is 500W, the illuminance is 120klx, and the distance from...

Embodiment approach 2

[0022] 0.5g BiBr 3 Add it into 15mL of ethylene glycol solvent, stir and dissolve at room temperature for 1h, after a clear liquid is formed, add 1mL of NH 3 ·H 2 O, adjust the pH value of the solution to 8, and then continue to react under this condition for 6h until the precipitate is formed, and the resulting precipitate is separated, washed and dried to obtain Bi 4 o 5 Br 2 Catalyst, denoted as Bi 4 o 5 Br 2 -B.

[0023] Income Bi 4 o 5 Br 2 -B photocatalyst is used for photocatalytic degradation of resorcinol and bisphenol A solution. The reaction conditions are: normal temperature and pressure, the amount of catalyst is 0.1g, and the treatment amount of organic pollutant resorcinol or bisphenol A in water is 50mL, 10mg·L -1, the light source used is a xenon lamp, the power is 500W, the illuminance is 120klx, and the distance from the reaction interface is 20cm, and the emitted light is visible light with a wavelength greater than 420nm. The photocatalytic deg...

Embodiment approach 3

[0025] 0.5g BiBr 3 Add it into 15mL of propylene glycol solvent, stir and dissolve at room temperature for 2h, after forming a clear liquid, add 1mL of NH 3 ·H 2 O, adjust the pH of the solution to 8, and then react for 8 hours until the precipitate is formed, and the precipitate is separated, washed and dried to obtain Bi 4 o 5 Br 2 Catalyst, denoted as Bi 4 o 5 Br 2 -C.

[0026] Income Bi 4 o 5 Br 2 -C photocatalyst is used for photocatalytic degradation of resorcinol and bisphenol A solution. The reaction conditions are: normal temperature and pressure, the amount of catalyst is 0.1g, the treatment amount of organic pollutant resorcinol or bisphenol A in water is 100mL, 10mg·L -1 , the light source used is a xenon lamp, the power is 500W, the illuminance is 120klx, and the distance from the reaction interface is 20cm, and the emitted light is visible light with a wavelength greater than 420nm. The photocatalytic degradation experiment of diphenol or bisphenol A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com