Automatic discharge mechanism for coiler for trimmings

An automatic unloading and edge rolling technology, applied in the field of waste edge coiling machine, can solve the problems of increasing operating time and energy of operators, damage to waste edge rolling equipment, etc., to reduce unloading time, reduce workload, and avoid scratching The effect of wounding and smashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

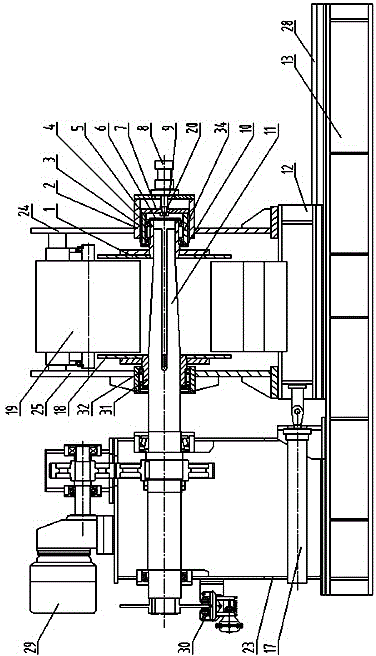

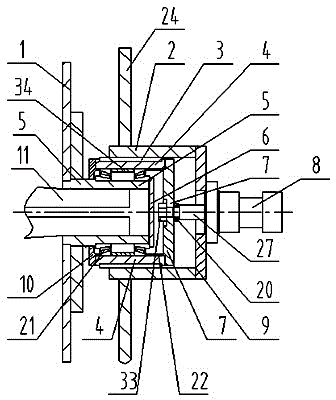

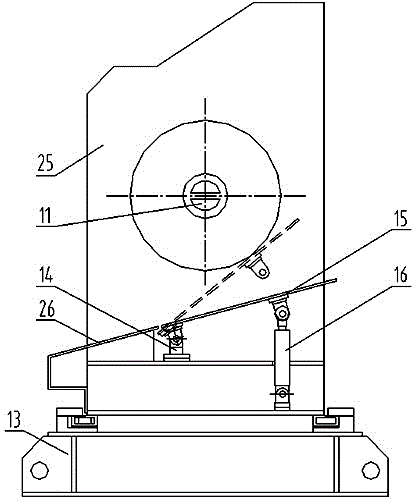

[0015] like figure 1 , figure 2 The shown automatic unloading mechanism of a waste edge coiler includes a base 13, on which a fixed seat 23 and a movable seat 12 are arranged, and the base 13 is provided with a slide rail 28 extending forward and backward in a guiding direction, and the movable The seat 12 is slidingly assembled on the slide rail 28, and the unwinding oil cylinder 17 hinged with the two is provided between the movable seat 12 and the fixed seat 23, and the rotation of the axial limit on the fixed seat 23 is equipped with a rotary shaft 11, and the rotary shaft 11 The axis of rotation of the rotary shaft extends along the front and rear directions. The front end of the rotary shaft 11 is provided with a recovery section for reclaiming corresponding waste edges. The rotary shaft 11 is connected with the drive motor 29 through a transmission mechanism.

[0016] The movable seat 12 is provided with a front vertical plate 24 and a rear vertical plate 25 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com