Non-back gouging submerged-arc welding method of H-shaped steel

A technology of H-beam and submerged arc welding, which is applied in arc welding equipment, welding equipment, workpiece edge parts, etc., can solve the problems of low welding efficiency and poor welding quality, reduce the loss of welding materials, reduce the amount of milling, and is suitable for wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, the thickness of the H-shaped steel plate is 16mm, the material of the base metal is Q235B, the welding wire used is H08A, the diameter of the welding wire is 5mm, and the flux is SJ101, which requires full penetration and root cleaning welding.

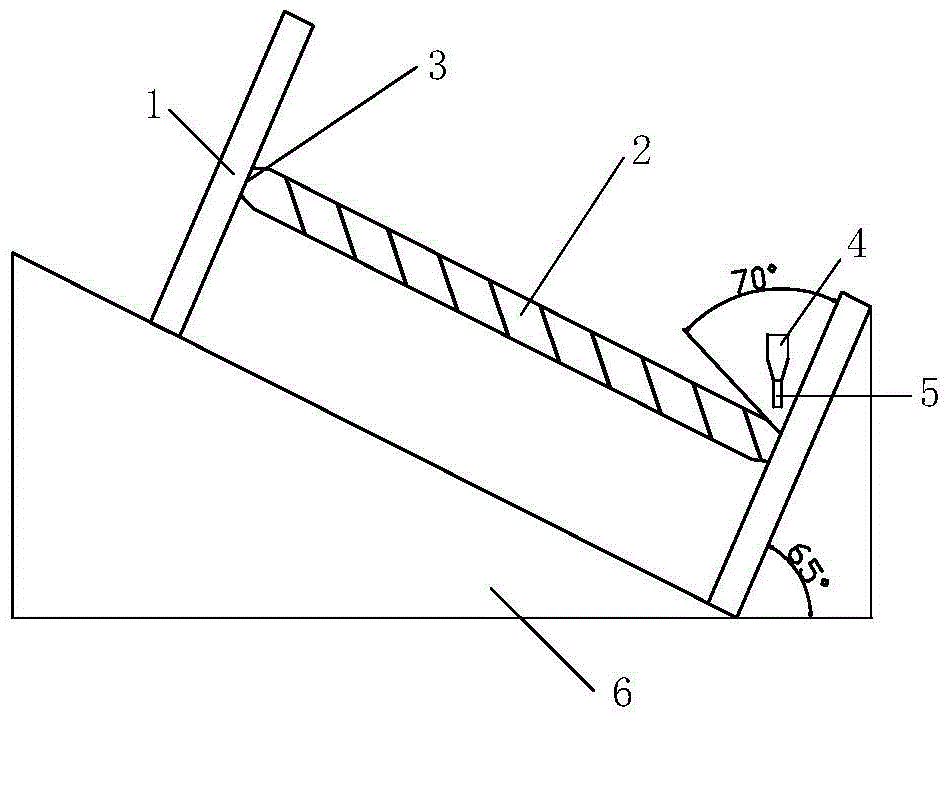

[0038] see figure 1 , adopt the method of the present invention to comprise the following steps:

[0039] Preparation before welding:

[0040] 1) Make a K-shaped symmetrical bevel on the web 2, the bevel angle is 70°, and the blunt edge 3 is 14mm;

[0041] 2) Remove the scale, rust and oil on the groove surface and near the weld, and polish it smoothly;

[0042] 3) Group pair, control the gap between the group pair to 0.5mm, and at the same time ensure that the axis of welding wire 5 is aligned with the center of the gap, the axis of welding wire 5 is perpendicular to the horizontal plane, and spot weld the web 2 and wing 1;

[0043] 4) Carry out grinding treatment on the tack welding place, with reference ...

Embodiment 2

[0052] In this example, the thickness of the H-shaped steel plate is 14mm, the material of the base metal is Q235B, the welding wire used is H08A, the diameter of the welding wire is 5mm, and the flux is SJ101, which requires full penetration and root cleaning welding.

[0053] see figure 1 , adopt the method of the present invention to comprise the following steps:

[0054] Preparation before welding:

[0055] 1) Make a K-shaped symmetrical bevel on the web 2, the bevel angle is 68°, and the blunt edge 3 is 12mm;

[0056] 2) Remove the scale, rust and oil on the groove surface and near the weld, and polish it smoothly;

[0057] 3) Group pairs, control the gap between the groups to be 0 mm, and at the same time ensure that the axis of the welding wire 5 is aligned with the center of the gap, the axis of the welding wire 5 is perpendicular to the horizontal plane, and spot weld the web 2 and the wing 1;

[0058] 4) Carry out grinding treatment on the tack welding place, with...

Embodiment 3

[0066] In this example, the thickness of the H-shaped steel plate is 18mm, the base material is Q235B, the welding wire used is H08A, the diameter of the welding wire is 5mm, and the flux is SJ101, which requires full penetration without root cleaning.

[0067] see figure 1 , adopt the method of the present invention to comprise the following steps:

[0068] Preparation before welding:

[0069] 1) Make a K-shaped symmetrical bevel on the web 2, the bevel angle is 72°, and the blunt edge 3 is 16mm;

[0070] 2) Remove the scale, rust and oil on the groove surface and near the weld, and polish it smoothly;

[0071] 3) Group pairs, control the gap between the group pairs to be 1 mm, and at the same time ensure that the axis of the welding wire 5 is aligned with the center of the gap, the axis of the welding wire 5 is perpendicular to the horizontal plane, and spot weld the web 2 and the wing 1;

[0072] 4) Carry out grinding treatment on the tack welding place, with reference t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com