High-accuracy powerful hydraulic machine

A hydraulic press, powerful technology, applied in punching presses, presses, fluid pressure actuating devices, etc., can solve the problems of heavy volume, inconvenient transportation and use, large shape of hydraulic cylinders, etc., to achieve small size, convenient production layout, human body low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1

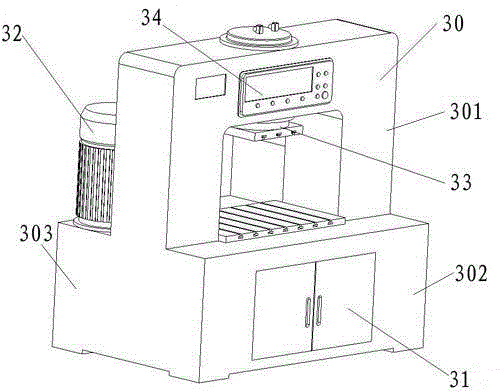

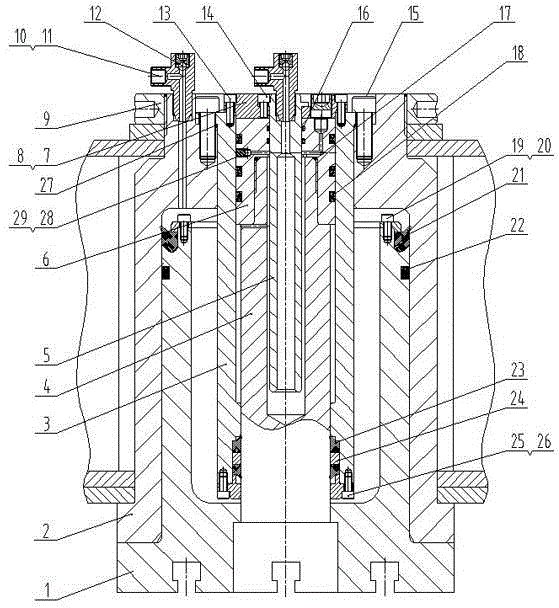

[0040] Such as figure 1 with figure 2 As shown, the high-precision powerful hydraulic press of the present invention includes a frame body 30, the middle part of which is a working area, and a hydraulic cylinder 33 is arranged above the working area, wherein the rear portion of the frame body 30 is set as A hydraulic station 32 , the hydraulic station 32 communicates with the hydraulic cylinder 33 to supply liquid; the front part of the frame body 30 is provided with an electric control cabinet 31 , and the electric control cabinet 31 is connected to and controls the hydraulic station 32 . The hydraulic cylinder 33 is located above the middle of the working area, and an electric control board 34 is arranged above the working area, and the electric control board 34 is connected to the electric control cabinet 31 . The high-precision powerful hydraulic machine can be a monolithic structure or a combination of split structures, so the front part of the fra...

Embodiment 2

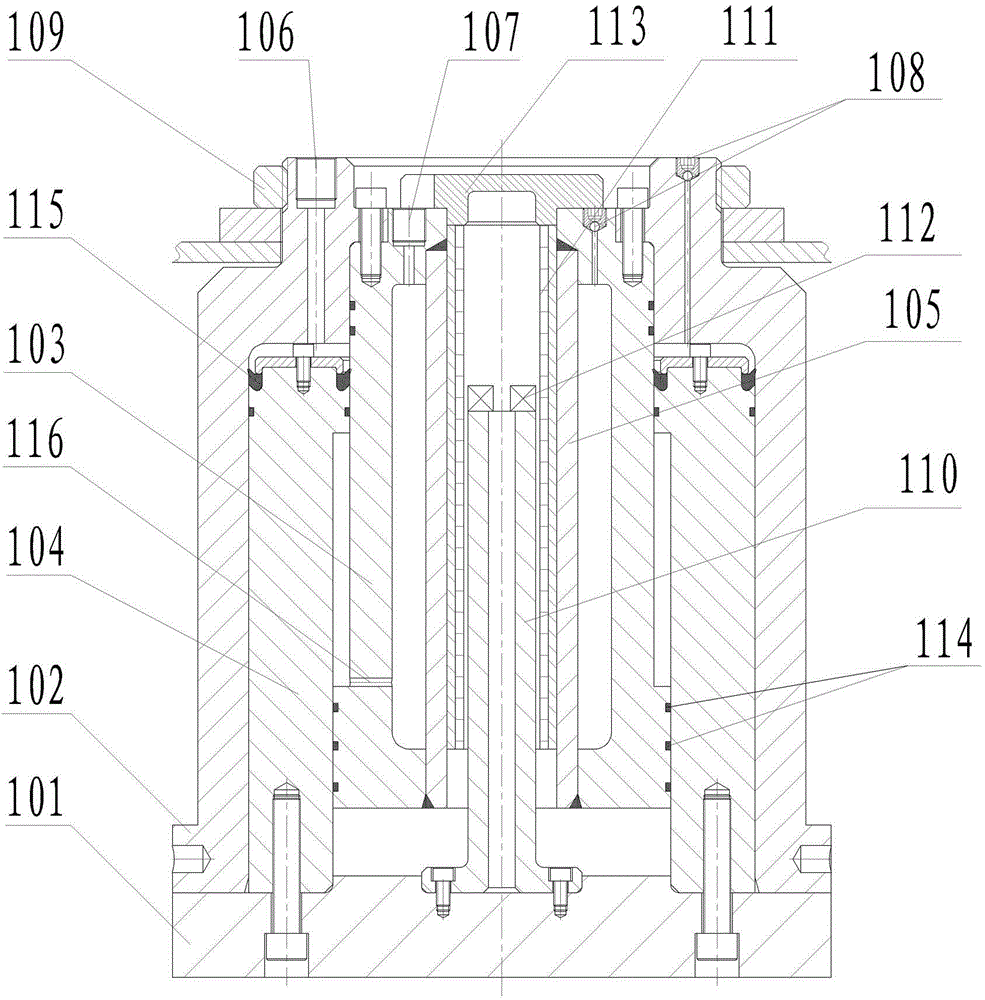

[0045] Such as image 3 with Figure 4 As mentioned above, this embodiment is similar to Embodiment 1, except that the hydraulic cylinder 33 adopts a different structure. In the high-precision and powerful hydraulic machine of the present invention, the hydraulic cylinder 33 includes a master cylinder block 102, so The inner top of the master cylinder body 102 is sealingly connected with a return cylinder body 103, and a cylindrical main plunger 104 is sleeved between the inner wall of the master cylinder body 102 and the outer wall of the return cylinder body 103, and the top of the main cylinder body 104 is The inner and outer walls are respectively provided with dynamic seals, that is, the top outer wall of the main plunger 104 and the top inner wall of the main plunger 104 are respectively provided with L-shaped sealing rings 105, so that the main plunger 104 and the master cylinder A dynamic seal is formed between the body 102 and the return cylinder body 103 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com