Over-speed dynamic capture hydraulic system for rail transportation carts

A technology of rail transportation and hydraulic system, which is applied to the operating mechanism of railway vehicle brakes, railway braking systems, transportation and packaging, etc. It can solve the problems of poor system reliability, easy off-track, poor track adaptability, etc., and achieve a high rate of malfunction Low, avoid falling off the road, fast braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

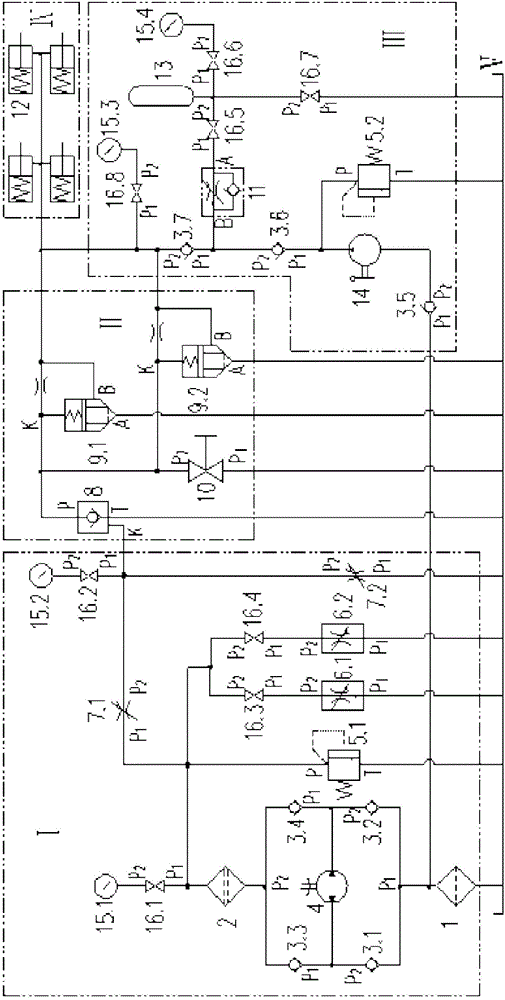

[0032] figure 1 Among them, the present invention includes a signal detection part I, a pressure relief part II, a liquid filling part III, an execution part IV and a fuel tank V; the P of the second throttle valve 7.2 of the signal detection part I 2 The port is connected to the K port of the hydraulic control check valve 8 of the pressure relief part II; the liquid outlet of the coarse filter (1) of the signal detection part I is connected to the P port of the No. 5 check valve 3.5 of the liquid filling part III 1 Port connection, port B of No. 1 cartridge valve 9.1 of pressure relief part II, port B of No. 2 cartridge valve 9.2 and P of No. 7 one-way valve 3.7 of liquid filling part III 2 The port is connected to the liquid inlet and outlet of the brake cylinder 12 piston rod cavity of the executive part IV; the oil return port of the detection part I, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com