Method for preparing bismuth selenide micron-tablet

A technology of micron flakes and bismuth selenide, applied in the direction of binary selenium/telluride compound, metal selenide/telluride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

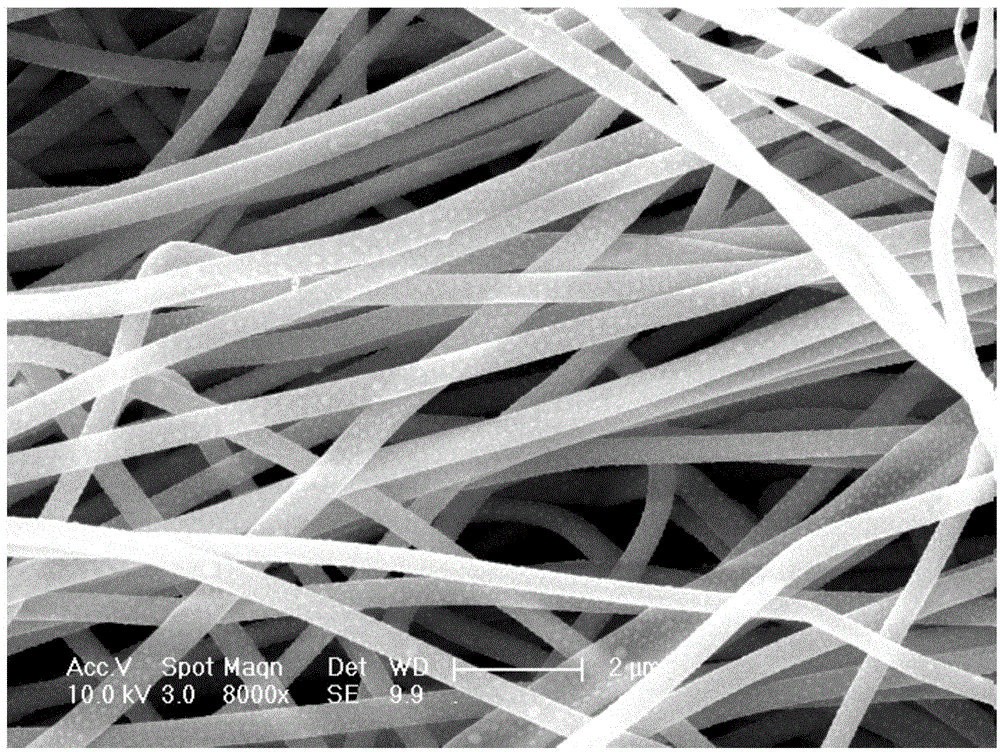

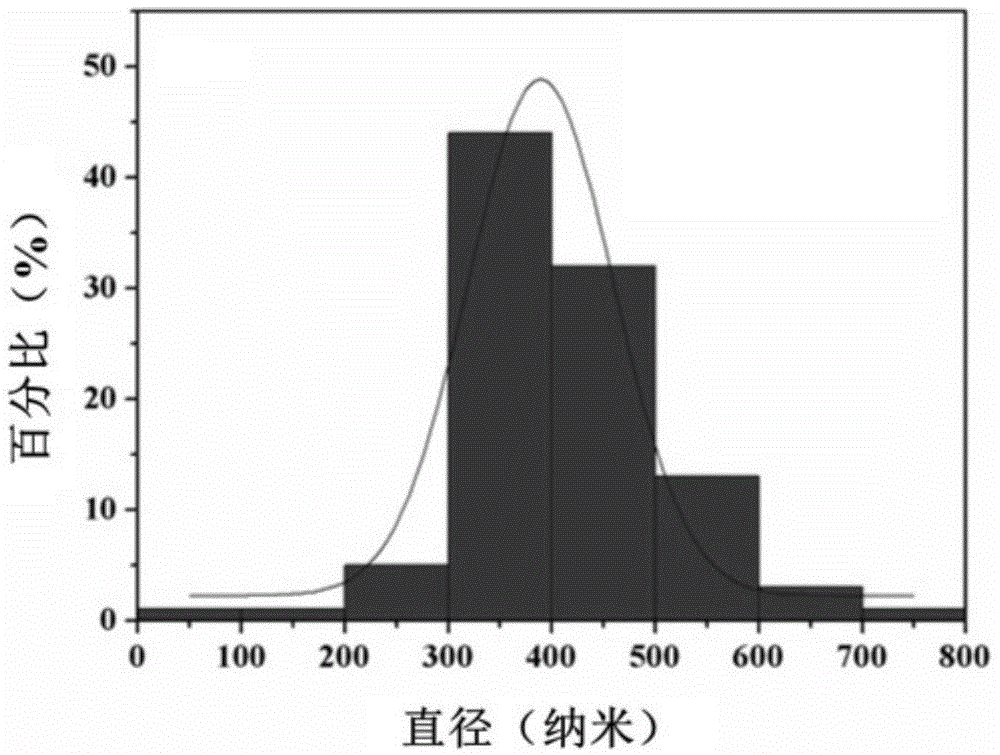

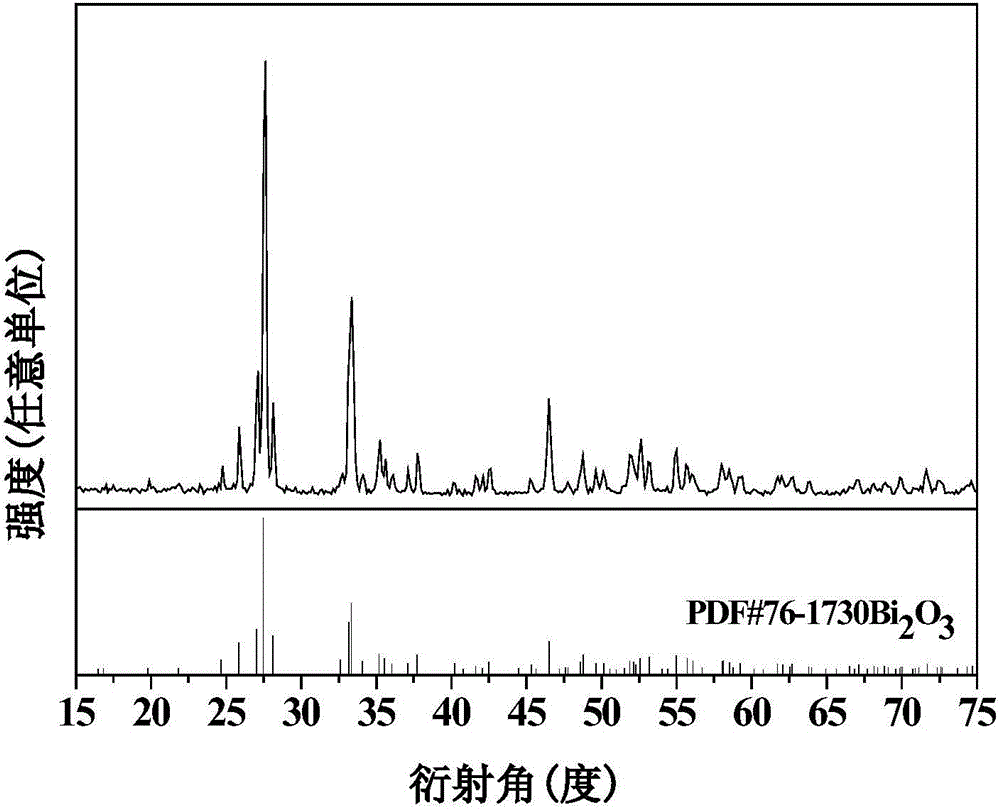

[0028] Example: 4.9110g Bi (NO 3 ) 3 ·5H 2 O was dissolved in 13.6g DMF, and 2.4g PVP was added after magnetic stirring to dissolve it. After stirring for 12h, a uniformly dispersed spinning solution was obtained; the spinning solution was injected into a 10mL syringe with a 1mL plastic spray gun, and an aluminum wire was inserted. As the anode, use the wire mesh receiving device as the cathode, adjust the angle between the nozzle and the horizontal plane to be 30°, the distance between the nozzle and the wire mesh to be 18cm, the spinning voltage to be 13kV, the ambient temperature to be 20-25°C, and the relative humidity to be 20%-30 %, get PVP / Bi (NO 3 ) 3 composite nanofibers; the PVP / Bi (NO 3 ) 3 The composite nanofibers were placed in a porcelain crucible, placed in a temperature-programmed furnace, heated to 450°C at 1°C / min, held for 3 hours, then cooled to 200°C at a rate of 1°C / min, and then cooled to room temperature naturally with the furnace body , get Bi 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com