Preparation method of two-dimensional gallium telluride material

A technology of gallium telluride and adhesive tape is applied in the field of preparation of two-dimensional gallium telluride materials, which can solve the problems such as the inability to meet the requirements of large-area two-dimensional materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

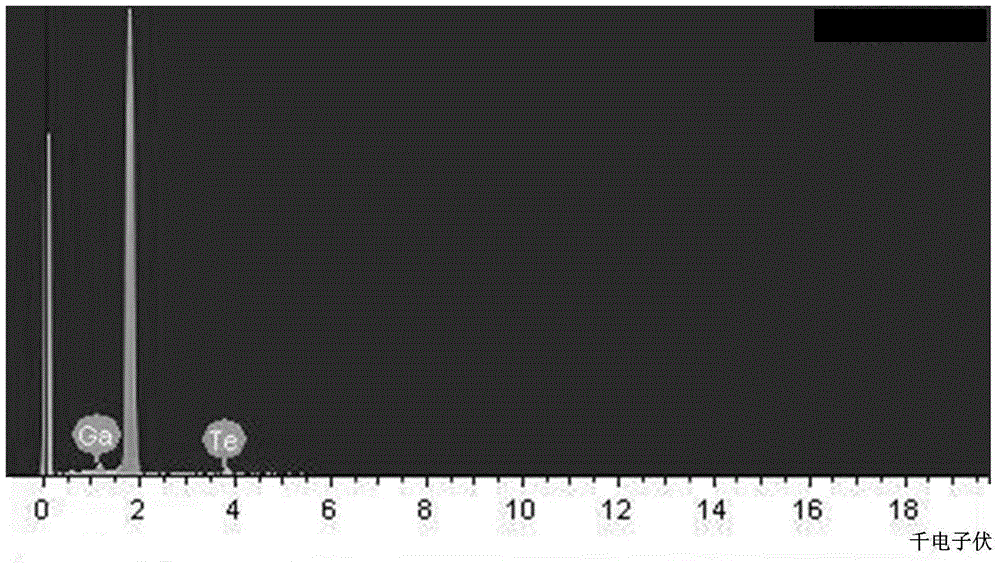

[0022] In step 1, the vertical Bridgman crystal growth method is used to mix Ga:Te according to the material ratio of 1:1 to prepare a GaTe single crystal.

[0023] Step 2: In the Michelon Universal 2440-750 glove box under the Ar atmosphere, select a large GaTe bulk material with a smooth surface and no wrinkles, and separate it into two pieces along the natural cleavage plane.

[0024] Step 3: In the Michelon Universal 2440-750 glove box under the Ar atmosphere, use Scotch tape to tear off a GaTe sheet with a thickness of about 6 μm from the surface of the GaTe bulk material with a bright surface and less damage.

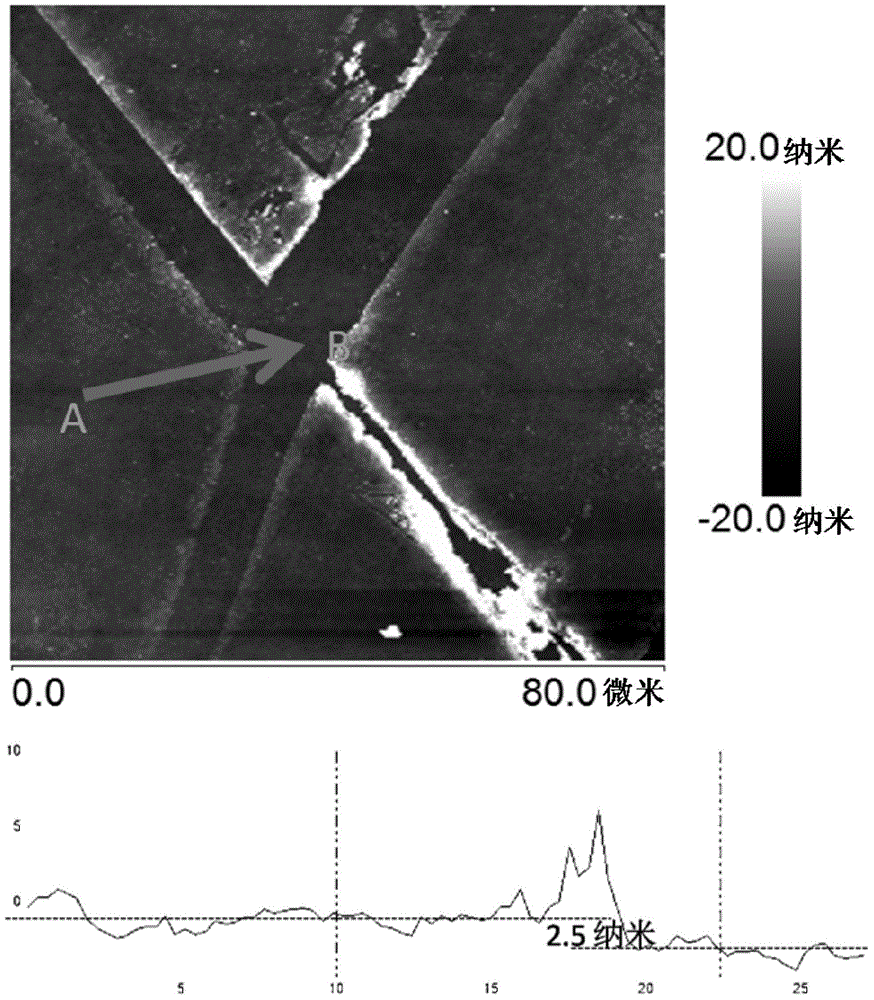

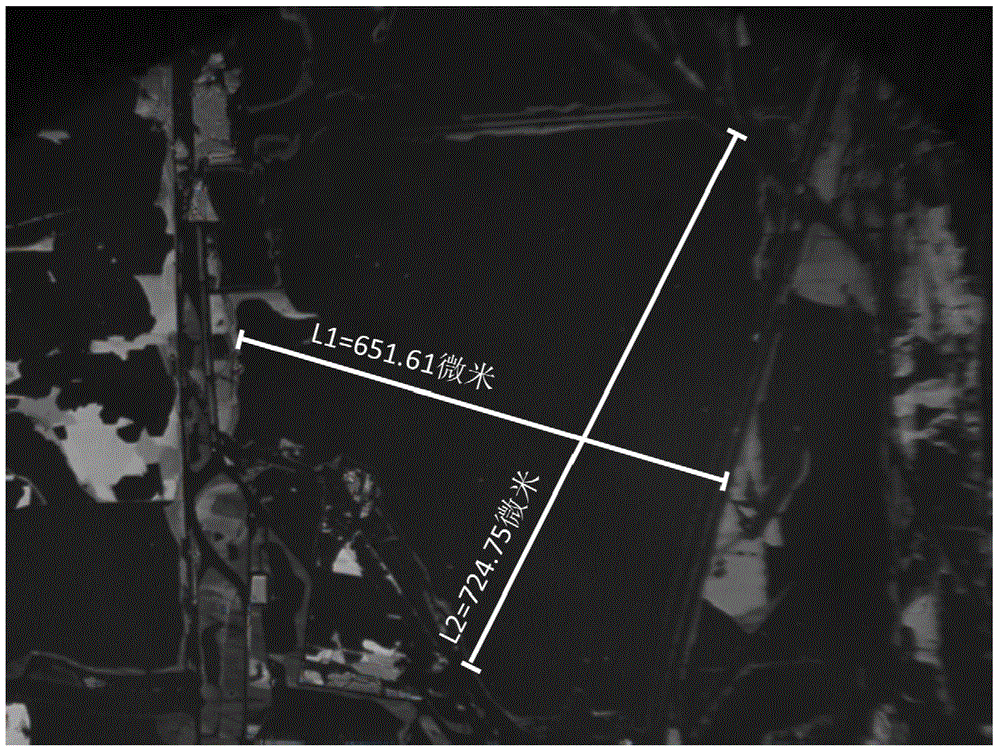

[0025] In the fourth step, in the Michelon Universal 2440-750 glove box under the Ar atmosphere, the Scotch tape with the GaTe flakes was bonded and separated 15 times until the surface of the tape was no longer bright, and a relatively dense 200nm thickness was successfully attached. GaTe flakes. In order to protect the flat surface of the GaTe bulk material, th...

Embodiment 2

[0030] In step 1, the vertical Bridgman crystal growth method is used to mix Ga:Te according to the material ratio of 1:1 to prepare a GaTe single crystal.

[0031] Step 2: In the Michelon Universal 2440-750 glove box under the Ar atmosphere, select a large GaTe bulk material with a smooth surface and no wrinkles, and separate it into three pieces along the natural cleavage plane.

[0032] Step 3: In the Michelon Universal 2440-750 glove box under the Ar atmosphere, use Scotch tape to tear off a GaTe sheet with a thickness of about 8 μm from the surface of the GaTe bulk material with a bright surface and less damage.

[0033] In the fourth step, in the Michelon Universal 2440-750 glove box under the Ar atmosphere, the Scotch tape with the GaTe flakes was bonded and separated 15 times until the surface of the tape was no longer bright, and a relatively dense 210nm thickness was successfully attached. GaTe flakes. In order to protect the flat surface of the GaTe bulk material, ...

Embodiment 3

[0042] In step 1, the vertical Bridgman crystal growth method is used to mix Ga:Te according to the material ratio of 1:1 to prepare a GaTe single crystal.

[0043] Step 2: In the Michelon Universal 2440-750 glove box under the Ar atmosphere, select a large piece of GaTe bulk material with a smooth surface and no wrinkles, and separate it into four pieces along the natural cleavage plane.

[0044] Step 3: In the Michelona Universal 2440-750 glove box under the Ar atmosphere, use Scotch tape to tear off a GaTe sheet with a thickness of about 7 μm from the surface of the GaTe bulk material with a bright surface and less damage.

[0045] In the fourth step, in the Michelon Universal 2440-750 glove box under the Ar atmosphere, the Scotch tape with the GaTe flakes was bonded and separated 15 times until the surface of the tape was no longer bright, and a relatively dense 210nm thickness was successfully attached. GaTe flakes. In order to protect the flat surface of the GaTe bulk m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com